Pos:

Home KnowledgeTechnologyBoron-doped single-crystal diamond exhibits excellent electrical propertiesAmong various semiconductor materials, diamond boasts the most superior properties. It integrates the excellent characteristics of numerous wide-bandgap semiconductors (with a bandgap Eg>2.3eV), featuring a large bandgap width (5.45 eV), an extremely high critical breakdown electric field Ec (exceeding 106V/cm and varying with doping concentration), a high saturation velocity (2.8×10⁷ cm/s), a small dielectric constant (εr=5.5), relatively high electron mobility, strong radiation resistance, and high wear resistance. These properties make it conducive to manufacturing electrically coupled devices and non-volatile high-performance memory. Additionally, diamond has the highest thermal conductivity (), which is advantageous for producing high-power amplifiers and lasers. Its insulation strength is remarkably high—33 times that of silicon (Si)—rendering it suitable for manufacturing high-power amplifier switches and diodes.

Diamond’s figure of merit (the product of the maximum allowable voltage and cutoff frequency) surpasses that of all existing semiconductor materials. For instance, the figure of merit of n-type diamond is over 90 times that of Si. Today, while silicon device technology is quite mature, it is approaching its development limits; thus, researching a new generation of diamond semiconductor devices holds significant importance. Currently, research on micro-electro-mechanical systems (MEMS) fabrication primarily focuses on silicon-based micromachining, including surface silicon micromachining technology and bulk silicon micromachining technology. However, these silicon devices fail and cease to operate at temperatures above 80°C, which limits their applications.

With appropriate doping, diamond films can be transformed into excellent semiconductor materials or conductive materials. Compared with other semiconductor materials, diamond exhibits outstanding high thermal conductivity and high breakdown electric field characteristics. These attributes enable it to serve as a material for high-frequency and high-energy devices, which can be widely applied in sectors such as electronics, machinery, optics, aerospace, and the military industry—particularly in micro-electro-mechanical systems (MEMS).

Due to the rarity and high cost of natural diamonds, as well as the small particle size of diamonds synthesized via high-temperature and high-pressure (HTHP) methods, they are rarely used except in the production of special devices. Chemical vapor deposition (CVD) diamond, however, has opened up possibilities for its application in the field of semiconductors. From a technical perspective, research on diamond thin-film semiconductors follows two main approaches: one is the heteroepitaxial growth of doped single-crystal diamond films, and the other is the growth of polycrystalline diamond semiconductor films on non-diamond substrates. The targeted applications of these films lie in semiconductor devices, particularly in high-temperature, high-voltage, and high-radiation environments where silicon (Si) and gallium arsenide (GaAs) semiconductors are inapplicable, as well as in high-frequency and high-power microwave solid-state devices.

Currently, only boron doping of diamond has been realized, with significant progress made. Nevertheless, boron-doped diamond has a relatively high activation energy (0.37 eV), meaning that only a small portion of boron atoms contribute carriers to the valence band at room temperature. This results in a much higher resistivity of diamond films (10–100 Ω·cm) compared to silicon (0.5 Ω·cm) under the same doping concentration. Even so, thanks to the high breakdown electric field characteristic of diamond films, high-voltage and high-power diamond film sensors still exhibit lower resistance than similar devices made from Si and GaAs. The commonly used Si piezoresistive micro-sensors today can no longer operate normally at temperatures above 300°C and are unsuitable for use in harsh chemical environments, high-radiation environments, and high-temperature environments. In contrast, even polycrystalline diamond films have a piezoresistive coefficient of over 1000 at room temperature. This property allows them to be used in manufacturing a new category of excellent, unique, and widely applicable high-sensitivity sensor materials and devices, thereby further promoting the industrial application of diamond films.

The impurity energy levels in a crystal depend on how impurities interact with the electronic and geometric periodic structure of the host lattice. They are determined by the lattice position, size, and electronic shell structure of the impurities, with which the maximum solid solubility is closely associated. In the diamond lattice, impurity atoms participate in chemical bonding, and their diffusion behavior and electrical activity form a complex function of lattice integrity and diffusion conditions. To analyze the behavior of a given impurity in a diamond matrix, it is essential to calculate the formation energy (E₁), impurity diffusion, and solid solubility (S). The relationship between the formation energy (E) and the solid solubility (S) is as follows:

Currently, significant progress has been made in the research on boron-doped p-type diamond films. Their resistivity at room temperature can reach the level of 10² Ω·cm, and the activation energy is 0.013 eV, which has met the application requirements. However, their energy levels are relatively deep, and the resistivity is sensitive to temperature. For p-type diamond films, since boron is incorporated into diamond as an acceptor impurity, and boron is a deep-level impurity with an activation energy of approximately 0.31 eV, only about 1% of boron acceptors are activated at room temperature. Therefore, diamond is highly sensitive to changes (even minor ones) in the activation energy of boron. The boron concentration of the sample is determined by combining Secondary Ion Mass Spectrometry (SIMS) analysis with Hall coefficient measurement. Using the relationship between film resistivity and temperature, the Arrhenius equation is applied: ρ = const·exp(W/(kT)), where ρ is the resistivity, W is the activation energy (ranging from 0.1 to 0.37 eV, and related to the doping concentration [9-21]). The relationship between the activation energy of the diamond film and the doping concentration can be derived by varying the impurity concentration over a wide range. When the doping concentration is 10¹⁸ cm⁻³, W ≈ 0.32 eV; when the doping concentration is 10²¹ cm⁻³, W < 10⁻³ eV.

At low doping concentrations, the ionization energy of boron acceptor atoms is relatively high (0.37 eV), and only 0.2% of acceptor atoms are ionized at room temperature, which poses difficulties for the application in electronic devices. At relatively high doping concentrations, the activation energy (W) decreases, but variable-range hopping conduction occurs between ionized boron atoms, accompanied by a decrease in hole mobility. At even higher doping concentrations, due to the formation of impurity bands, W further decreases, and the metallic conductivity no longer changes with temperature.

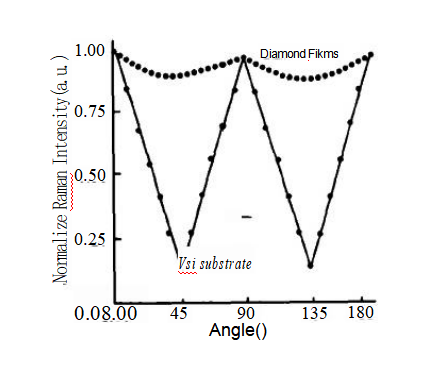

High-concentration boron doping causes significant changes in the structure of diamond films, thereby seriously affecting their electrical properties. To meet the requirements of electronic devices, it is necessary to strictly control the doping concentration of diamond films, while also reducing defects and improving film perfection.

High-quality electronic components require high-quality epitaxial diamond films. However, most diamond films prepared by the Chemical Vapor Deposition (CVD) method are polycrystalline films. In polycrystalline diamond films, the high density of defect states and a large number of grain boundaries greatly reduce the carrier mobility, which severely limits the application of diamond films in electronic devices. The difficulty in preparing large-area single-crystal diamond films has become one of the major technical obstacles to vigorously advancing the research on the application of diamond films. It is essential to further clarify the growth mechanism of CVD diamond films both theoretically and experimentally to continuously improve the technical level of diamond film fabrication and synthesize high-quality epitaxial single-crystal diamond films. Meanwhile, in-depth research on diamond film doping technology, optimal design of device structures, and optimization of electrode ohmic contacts are all key research contents for further promoting the application of diamond films in electronics and realizing their industrialization.

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message