Pos:

Home KnowledgeTechnologyDiamond Heat Sink: Fueling the Material Revolution of UAVs from Structural Support to Intelligent FlightAs a product of the integration of modern aviation technology and artificial intelligence, the material selection of UAVs directly determines their flight performance, mission capabilities, and service life. The UAV material system has evolved from a single metal material to a multi-component composite material system. Modern UAV material design adheres to the principle of "the right material for the right part," pursuing the organic unity of lightweight, high strength, multi-functionality, and intelligence.

The core requirements of UAVs for metal materials can be summarized into four aspects:

Structural efficiency requires high specific strength and high specific stiffness to achieve maximum load capacity and endurance;

Environmental adaptability demands corrosion resistance, fatigue resistance, and high-temperature resistance to ensure reliability in complex environments;

Functional integration requires materials to possess special properties such as electrical conductivity, thermal conductivity, and stealth capabilities;

Manufacturing economy calls for good processability and low cost to support large-scale production.

In recent years, diamond materials have made significant progress in UAV transmission systems, as they can enhance data transmission rates, optimize equipment performance, and address endurance issues.

Nano-diamond reinforced copper matrix composites are used in high-load bearings, reducing the friction coefficient by 40% and extending the service life by more than 3 times;

Enabled by diamond heat sink wafer technology, UAVs can be put into operation within 1 minute of charging. Their ability to efficiently absorb high-density laser beams has completely resolved the endurance bottleneck;

The ultra-flexible characteristic allows diamond materials to be directly applied in elastic strain engineering and deformation sensing applications, accelerating the commercialization of diamond materials in UAV-related fields.

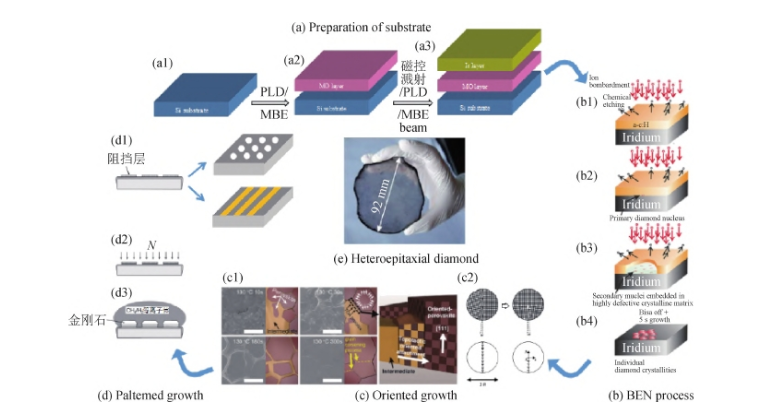

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message