Pos:

Home KnowledgeTechnologyDiamond Heat Sink Substrates Empower Raman Lasers for Multi-Scenario Applications: Technological Breakthroughs from HighRaman lasers, boasting advantages such as a broad wavelength tuning range and high beam quality, are indispensable in fields including astronomical observation, laser processing, and medical imaging. However, during high-power operation, the heat flux density in the active region can exceed 1000 W/cm², leading to increased device thermal resistance, attenuated output power, and shortened service life—traditional aluminum nitride (AlN) heat sinks (with a thermal conductivity of 230 W/(K·m)) can no longer meet such demands. Diamond heat sink substrates, featuring ultra-high thermal conductivity (up to over 1800 W/(K·m)), excellent thermal stability, and chemical inertness, have emerged as the core material to address this bottleneck. Their application directly drives Raman lasers to achieve breakthroughs toward higher power, miniaturization, and longer service life.

1. Thermal Dissipation Optimization for High-Power Continuous-Wave Raman Lasers

In high-power continuous operation scenarios, the low thermal resistance of diamond heat sink substrates is particularly critical. In a certain experiment, CVD diamond was used as a transition heat sink to package a 976 nm semiconductor laser chip. By matching the thermal expansion coefficient (the thermal expansion coefficient of the gallium arsenide chip is 4.5×10⁻⁶/K) through the flip-chip sintering process and indium solder, the device's thermal resistance was reduced from 2.91 °C/W with an AlN heat sink to 1.74 °C/W. At an injection current of 25 A, the junction temperature was only 53.94 °C, and the average output power reached 24.0 W, an increase of more than 30% compared with traditional solutions. This thermal dissipation optimization extends the continuous working time of Raman lasers from hundreds of hours to thousands of hours in fields such as industrial cutting and laser cladding.

2. Power Breakthrough for Sodium Guide Star Lasers

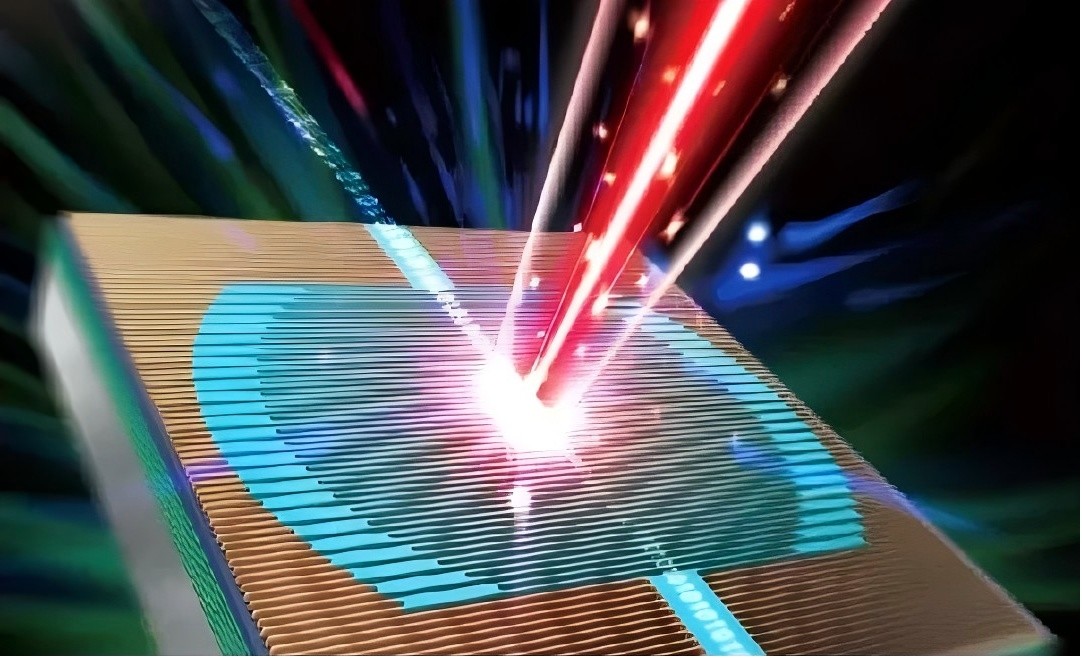

The synergistic application of diamond heat sink substrates and Raman crystals has solved the power limitation challenge of sodium guide star lasers. Leveraging the hole-burning-free effect of diamond Raman gain media, a V-shaped resonant cavity structure was constructed. A 1018 nm ytterbium-doped fiber laser was used as the pump source, and 589 nm sodium guide star laser output was achieved through intracavity frequency doubling. Benefiting from diamond's thermal conductivity of 2000 W/(K·m), the system achieved an intracavity power of up to 3200 W at a pump power of 75 W, with a Raman lasing threshold of only 16.8 W, providing a high-brightness guide star light source for astronomical observation. Such applications have become the core technical support for large-aperture telescopes.

3. Expansion of Multi-Wavelength and Specialized Raman Lasers

The broad spectral adaptability of diamond heat sink substrates has driven the development of multi-wavelength Raman lasers. In a 532 nm pulsed pump system, efficient thermal dissipation via diamond heat sinks enabled cascaded Raman output at 620 nm, 676 nm, and 743 nm, with a maximum conversion efficiency of 36.38% and a minimum pulse width of only 2.45 ns, meeting the sophisticated application requirements of biomedical imaging, spectral analysis, and other fields. In addition, in the field of vortex light, the combination of off-axis pumping and diamond heat sinks has realized the output of Gaussian fundamental mode (65.5 W) and LG mode (42.2 W) in the 1.2 μm and 1.5 μm wavebands. Its thermal management solution ensures mode stability, providing a new type of light source for quantum communication and particle manipulation.

The application of diamond heat sinks relies on precise packaging technology: a vacuum indium evaporation process is adopted, where parameters such as evaporation distance and current are controlled to form a buffer layer, reducing thermal mismatch stress; the primary sintering involves flip-chip mounting of the chip in a formic acid reducing atmosphere, and the secondary sintering uses indium-tin solder to achieve temperature gradient matching; finally, gold wire bonding ensures the reliability of electrical connections. This process minimizes the interfacial thermal resistance between the diamond heat sink and the device, increasing the heat dissipation efficiency by more than four times.

The selection of diamond type should be tailored to application scenarios: polycrystalline CVD diamond is preferred for high-power continuous lasers, whose isotropic thermal conductivity is suitable for complex cavity structures; single-crystal diamond can be used for pulsed lasers, and when combined with microchannel cooling design, it can withstand ultra-high heat flux density. The adoption of the Diamond-on-Cu solution controls the temperature rise of RF modules within 15 °C, providing a reference for integrated Raman laser systems.

In fields such as astronomical observation, industrial manufacturing, and biomedicine, diamond heat sink substrates have become the core key material for enhancing the performance of Raman lasers. In the future, it is necessary to further optimize interfacial thermal resistance and reduce manufacturing costs, driving this technology from high-end scientific research to large-scale industrial applications, and injecting new impetus into the innovation of laser technology.

As a leading manufacturer in the diamond semiconductor industry,CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), which has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message