Pos:

Home KnowledgeTechnologyThermal Conductivity Enhancement of Low-Cost Diamond Composite Materials via Cr₃C₂ Interface DesignWith the continuous miniaturization of semiconductor technology nodes, the integration density of modern electronic and high-power devices has achieved an unprecedented increase. This technological advancement inevitably brings about thermal management challenges: the increased transistor density leads to an exponential rise in power density. If heat cannot be effectively dissipated, it may cause thermal failure of devices, and traditional thermal interface materials can hardly meet the heat dissipation requirements of next-generation high-power-density electronic equipment. Metal matrix composites have emerged as a potential solution due to their tunable thermophysical properties by selecting reinforcement phases. Current studies mostly use micron-sized monocrystalline diamond (MBD) particles (180-220 μm) as reinforcement phases. Although these particles can provide excellent thermal performance, the complex preparation process results in excessively high costs, limiting the industrial production of diamond-copper composites. In addition, diamond micropowder (30 μm and below), a by-product of diamond cutting, can reduce costs but suffers from poor interfacial wettability and permeability with the copper matrix, making it difficult to form a stable bond. This issue restricts its application in thermally conductive composites.

In this study, diamond micropowder with an average particle size of 30 μm, chromium powder with a purity of 99.5 wt%, and copper powder with a purity of 99.99 wt% (average particle size of 20 μm) were used as raw materials. First, the diamond micropowder was pretreated: it was sequentially treated with 0.5 mol/L sulfuric acid and 0.5 mol/L sodium hydroxide solutions, rinsed with deionized water to remove residues, and then subjected to microwave irradiation at 800 W for 15 minutes. Subsequently, a Cr₃C₂ coating was prepared on the surface of the diamond micropowder via the molten salt method. The pretreated diamond micropowder and chromium powder were mixed at molar ratios of 100:3.5, 100:4.5, and 100:5.5, covered with a mixed salt of KCl and NaCl at a molar ratio of 8:10, and sintered in a tube furnace at 950 °C under a vacuum of 1×10⁻³ Pa for 30 minutes. Finally, the metallized diamond micropowder and copper powder were mixed at a specific volume ratio, placed in a graphite mold, and sintered in a hot-pressing furnace at 850 °C under vacuum for 1 hour to prepare the diamond-copper composite.

In terms of coating and microstructure: when the molar ratio of diamond micropowder to chromium powder was 100:3.5, the coating had defects and could not fully encapsulate the diamond micropowder; at a molar ratio of 100:4.5, the Cr₃C₂ coating effectively encapsulated the micropowder, with a thickness of approximately 180 nm, a smooth surface, and no voids at the interface; at a molar ratio of 100:5.5, the coating could encapsulate the micropowder, but its thickness increased to about 410 nm and the surface became uneven. XPS analysis showed that the main component of the coating was Cr₃C₂, with an extremely thin chromium oxide layer on the surface; XRD patterns only detected the characteristic peaks of diamond and Cr₃C₂, with no Cr₇C₃ or Cr₃O₂ phases, confirming the completeness of the reaction. SEM and TEM analyses indicated that under the optimal molar ratio, the composite had a tight interfacial bond. The Cr₃C₂ layer formed a continuous heat transfer path of diamond-Cr₃C₂-copper, reducing interfacial voids, and the diamond micropowder was uniformly distributed in the copper matrix.

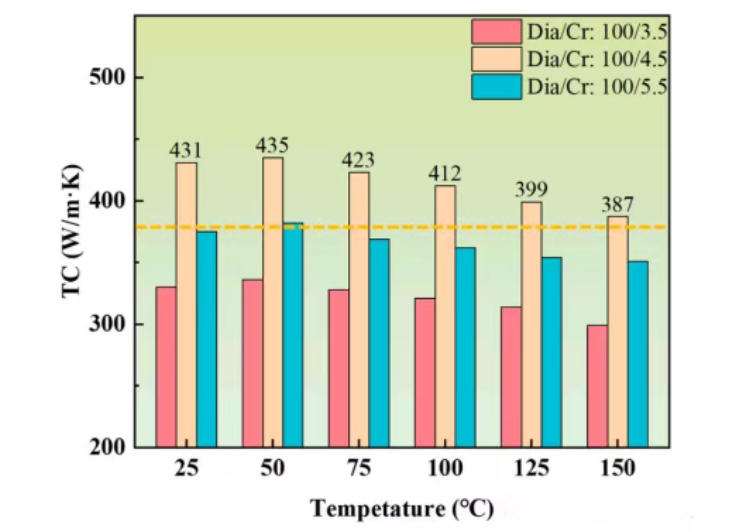

In the thermal conductivity tests: among the composites with a diamond volume fraction of 40%, the one with a molar ratio of 100:4.5 exhibited the highest thermal conductivity, reaching 431 W·m⁻¹·K⁻¹, and remained at 412 W·m⁻¹·K⁻¹ at 100 °C, which was higher than that of pure copper (approximately 380 W·m⁻¹·K⁻¹). As the temperature increased, the thermal conductivity of the composites showed an overall downward trend, mainly due to the shortened mean free path of electrons and phonons and the intensified phonon vibration of diamond. Finite element analysis revealed that an increase in the thickness of the Cr₃C₂ layer (e.g., 400 nm, 600 nm) led to a more obvious temperature gradient and increased heat loss, reducing heat transfer efficiency. In the air interface model, heat was mainly transferred along the copper matrix, while in the Cr₃C₂ interface model, more heat was transferred to the diamond phase, resulting in a more uniform temperature gradient. In practical application tests, when the composite was used for SSD chip packaging, its surface temperature was 61.4 °C at 300 s, which was 12.5 °C lower than that of SSDs without a heat dissipation layer and 2.5 °C lower than that of SSDs with a pure copper heat dissipation layer, demonstrating a significant heat dissipation effect.

In this study, by optimizing the molar ratio of diamond micropowder to chromium powder, the thermal conductivity of the diamond micropowder/copper composite was successfully enhanced. With diamond micropowder serving as the reinforcement phase, an optimal metal carbide interface was achieved at a molar ratio of 100:4.5, which effectively addressed the penetration issue of diamond micropowder in the copper matrix. This enhancement increased the thermal conductivity of the composite to 431 W·m⁻¹·K⁻¹, while the use of diamond micropowder also reduced the material preparation cost. Finite element simulation verified the influence of the metal carbide interface thickness on the thermal performance of the composite, and SSD read-write speed tests further confirmed the effectiveness of this composite in heat dissipation for electronic devices. This study provides a feasible approach for the development of low-cost, high-thermal-conductivity diamond-copper composites, promotes their application in thermal management fields such as electronic packaging, and also offers a reference for the subsequent research and development of thinner and lighter thermal management materials.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), and the surface roughness of diamond wafer a<1nm.It has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message