Pos:

Home KnowledgeTechnologyDiamond Wafer : Breaking the "High-Temperature Curse" of New Energy Vehicle Fast ChargingIn the fast-charging race of new energy vehicles, there lies a fatal challenge: the heat generated by massive currents and voltages is sufficient to melt traditional electronic components. Traditional heat dissipation solutions have proven powerless. Although copper and aluminum boast good thermal conductivity, they are also electrically conductive and require additional insulating layers, which in turn impede heat transfer. At this point, a material with the dual properties of "super thermal conductivity" and "perfect insulation" has emerged prominently — diamond wafers.

In the new energy megawatt fast-charging system, diamond materials are strategically deployed in three key locations:

In the power conversion module of charging piles, Insulated Gate Bipolar Transistors (IGBTs) and Metal-Oxide-Semiconductor Field-Effect Transistors (MOSFETs) are the most critical power devices. BYD’s megawatt charging piles adopt a 1000V high-voltage platform, which imposes extremely high requirements on power devices.

Diamond Solutions:

Diamond-substrate MOSFETs: A MOSFET structure based on diamond substrates has been developed, with a hydrogen-terminated layer formed on the diamond substrate, and a gate dielectric layer and gate electrode arranged on the surface.

Innovative Packaging Technology: Heat is efficiently conducted to the heat sink through large-area exposed pads, and 95% of the heat can be directly transferred to the liquid cooling system.

Faced with the enormous heat generated by 1000A high-current charging, the integration of diamond materials can further improve heat dissipation efficiency by 90%.

Diamond Solutions:

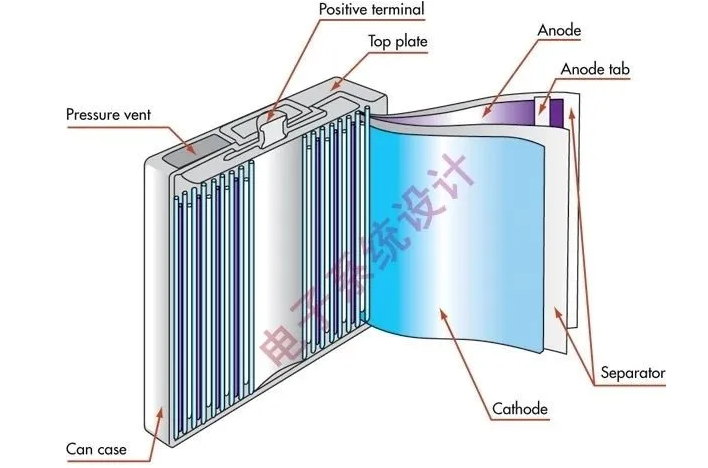

Diamond Coating on Battery Tabs: A 1-micron-thick diamond film is deposited on battery tabs (positive and negative electrode connectors), which reduces contact resistance while accelerating heat dissipation.

Diamond Heat Conduction Layer for Liquid Cooling Plates: A diamond heat conduction gasket is added between the liquid cooling plate and the battery module, with a thermal conductivity as high as 3.6W/m·K.

3D Diamond Heat Dissipation Frame: Structural components of the battery pack are made of composite materials filled with diamond micropowder, which balances structural strength and thermal management.

For gallium nitride (GaN) power devices used in on-board chargers and electric drive inverters, diamond substrates deliver remarkable performance:

Diamond Solutions:

GaN-on-Diamond Technology

The GaN devices are transferred onto diamond substrates via direct bonding technology.

Experimental data shows that:

At the same power density, the temperature of diamond-based GaN devices is 40% lower than that of silicon carbide-based counterparts, and the device lifespan can be extended by 10 times.

The output power can reach over 10W/mm at a high frequency of 10GHz, far outperforming traditional materials.

With the maturation of diamond processing technologies and the decline in costs, this cutting-edge material—once exclusive to the aerospace sector—is now shining brightly in the new energy vehicle field. It is not only the key to breaking the "high-temperature curse" of megawatt fast charging but also an important technological fulcrum for driving electric vehicles to comprehensively surpass fuel-powered vehicles.

The future is here. Electric vehicles enhanced with diamond are ushering in a new era of heat dissipation technology.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.CSMH offers high-quality diamond wafer substrates (e.g., on Si or SiC), whose surface roughness less than 1nm.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message