Pos:

Home KnowledgeTechnologyOptical Quality Laser Polishing of CVD Diamond by UV Pulsed Laser IrradiationIt is a great technical challenge to precisely polish diamond substrates due to their

extremely high hardness, especially for micro-optics fabrication. Here, a simple laser

polishing process is demonstrated for the optical quality surface finish of chemical

vapor deposition diamond using a 355 nm nanosecond laser. Raman spectroscopy and

surface profile analyses reveal that the laser polishing is an ablation-based process that

consists of laser graphitization and the subsequent laser ablation of the graphitized

layer. An optimized strategy is proposed to realize the high-quality polishing by

combining the ablation effect and defocusing laser irradiation. The polishing strategy

can effectively reduce the peak-to-valley height difference of a rough surface and

automatically enables the laser fluence at a low level close to the ablation threshold.

Laser polishing at such critical laser fluence can greatly avoid harmful effects caused by

high laser fluence and achieve precision materials’ removal while maintaining optical

surface quality. The approach is capable of delivering an average roughness Ra down to

8.02 nm and a high transmittance up to 80% of mechanically polished diamond in the

visible spectrum. High optical performances make it possible to directly fabricate

micro-optical components on diamond heat sink substrates using this novel laser polishing

approach.

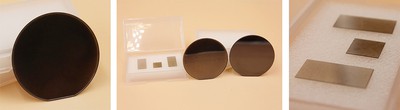

We focus on the R&D and production of heat sink diamonds. We have not only overcome the difficulties of "high speed, low deformation, high thermal conductivity, and large size" in the growth process, but also achieved success in the grinding and polishing process, cutting process and metallization process.A major breakthrough, achieving the world's leading technical indicators for diamond heat sinks and wafer-level diamond products.The surface roughness of the wafer-level diamond growth surface Ra<1nm, and the thermal conductivity of the diamond heat sink reaches 1000-2000W/m.K.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message