Pos:

Home KnowledgeTechnologyAccelerate! “The Ultimate Semiconductor” Diamond Chip Industrialization RevolutionCurrently, the semiconductor industry has entered a critical period of transition, silicon-based semiconductors encountered high-power, high-frequency, high-temperature and radiation bottlenecks. The third generation of semiconductors represented by GaN, SiC, leading power devices to high-power, miniaturization, integration and multifunctionality, but heat dissipation and energy efficiency is still the focus of the industry. In this context, the chip revolution driven by diamond materials quietly emerged, the essence of the unprocessed diamond. The emerging “diamond” chips are attracting attention for their unique charm and have great potential in the future, but they are also accompanied by technological progress and multiple challenges.

Diamond, known as “nature's hardest”, combines high hardness, excellent thermal conductivity, high electron mobility and high voltage, radio frequency, low cost, high temperature and other characteristics. Its semiconductor properties include ultra-wide bandwidth, high breakdown field strength, high-speed carrier drift, high thermal conductivity and excellent device quality factor, which is suitable for high-temperature, high-frequency, high-power, anti-irradiation electronic devices and solves the problems of “self-heating” and “avalanche breakdown”. Diamond also exhibits excellent optical transmittance, electrical insulation stability, and high mechanical strength and wear resistance, and is widely used in optoelectronic devices, complex circuits, and chips with extreme working conditions. It plays a key role in 5G/6G communications, microwave integrated circuits, sensing, and other fields, and is regarded as the “ultimate semiconductor material”. The use of diamond in electronic devices reduces the burden of thermal management, improves energy efficiency, and increases resistance to voltage and harsh environments.

Diamond is used in electric vehicles to improve power conversion efficiency, extend battery life, and shorten charging time; in 5G and future network deployments to meet high-frequency and high-power requirements, and to power communication equipment such as RF switches and amplifiers; and in consumer electronics to promote device miniaturization, high-speed, and high efficiency. According to Virtuemarket, the diamond semiconductor substrate market is forecas to grow from $151 million in 2023 to $342 million by 2030, with a CAGR of 12.3%. Its characteristic advantages promote diamond in semiconductor applications, covering thermal management, packaging, micro-nano-processing to BDD electrodes and quantum technology, leading technological innovation and industrial upgrading.

Global diamond semiconductor R & D and industrialization accelerated, a number of the world's leading enterprises to lead the technological breakthroughs and mass production plans. With the active participation of many countries, the industry chain has been gradually perfected, covering raw materials to packaging and testing. The industry is highly concerned about the acceleration of the process with the convergence of resources, heralding the arrival of the diamond wafer era. Diamond semiconductor with its excellent characteristics such as high thermal conductivity, wide bandwidth, etc., is moving towards a multi-functional development transition period. In the future, large-size high-quality diamond deposition technology will help integrated circuits into a new era.

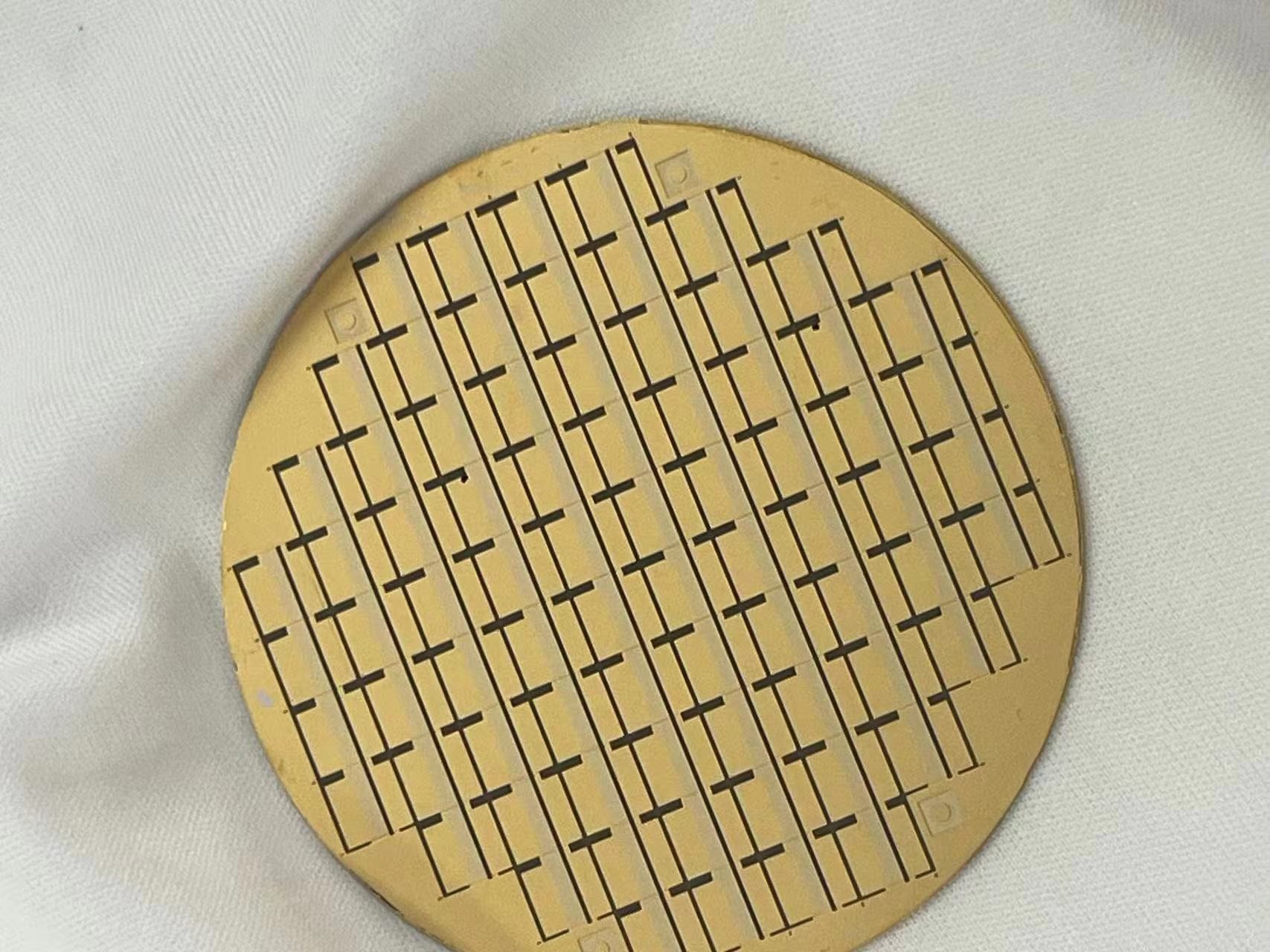

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds, and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows, diamond hetero junction integrated composite substrates, etc. Among them, the thermal conductivity of diamond heat sinks is 1000-2200W/(m.k), and the surface roughness of diamond wafer Ra<1nm. lt has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message