Diamond heat sink material has superior properties as a highly-conductive isotropic thermal management solution. It is the result of more than 10 years of intense development that only recently has been commercially available for use in power electronic applications and other high-heat-flux environments. Typical applications include heat spreaders and heat sinks for RF and microwave transistor and RFIC and MMIC packages (especially those based on Gallium Nitride – GaN), DC power device packages, laser diode packages, complex carriers for optoelectronics, and LEDs and detectors.

Diamond heat sink is a composite of high-thermal-conductivity industrial grade diamond ,for emerging RF and microwave applications (among others) makes it unchallenged. For example, it has:

Thermal conductivity greater than 500 W/mK, 80% higher than any other material for these applications.

Low coefficient of thermal expansion of 6 ppm/K at room temperature compatible with semiconductor materials

Low density of 3.17 g/cc, which reduces overall system weight in comparison to copper alloy heat spreaders.

In heat-spreading applications it provides far superior performance to conventional thermal management materials such as copper tungsten, copper moly, and copper moly copper.

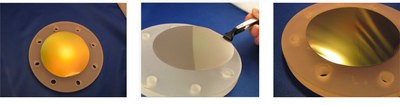

Heat spreaders can be nickel-gold electroless, gold electroless, or electrolytic plated, sputtered, CVR, or PVD

Is dimensionally stable and has a smooth surface finish and uniform flatness.

Netshape, multi-level, and irregular geometries can easily be fabricated.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message