High-power radio-frequency (RF) power amplifiers are used in military and commercial applications such as radar systems, electronic warfare, and cellular base stations. The latest high-power RF PAs consist of GaN epitaxial material, which performs exceptionally well at higher frequencies, boosts efficiency, and handles higher power densities.

However, these GaN RF devices have very small hotspots that can generate heat fluxes 10 times that of the sun’s surface. As a result, thermal-management challenges often severely limit their intrinsic performance advantages. GaN-on-diamond wafers eliminate this thermal limitation by bringing the diamond within less than one micron from the heat-generating gate junction.

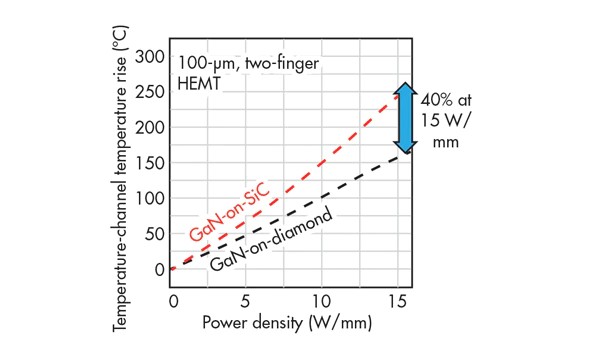

1. A plot of thermal-resistance measurements (peak channel temperature, derived from Raman measurements) demonstrates the heat-transfer superiority of GaN-on-diamond compared to GaN-on-silicon-Carbide. (Source: University of Bristol)

In one example, TriQuint fabricated identical HEMT’s (high electronic mobility transistors) on GaN-on-diamond substrates and GaN-on-SiC substrates. The University of Bristol used micro-Raman methodology to measure thermal resistances of the two transistor types, and found that the thermal resistance of the GaN-on-diamond HEMTs was at least 40% lower than that of the GaN-on-SiC HEMTs1(Fig. 1).

GaN-on-diamond technology offers two key benefits. First, it enables devices that are more than three times smaller than with other approaches, making them less expensive and providing much more power in a smaller form factor.2 Second, devices are able to run in ambient temperatures as much as 50% hotter, thereby lowering the cost of cooling subsystems and ultimately saving on-going energy expense.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message