Pos:

Home KnowledgeTechnologyApplication of boron-doped single-crystal diamond in Power Electronics - Schottky DiodesIn recent years, the rapid development of the electronic information industry has placed higher demands on high-performance semiconductor materials. However, traditional semiconductor materials still have problems such as insufficient thermal conductivity, low breakdown voltage, and difficulty in simultaneously increasing device power and frequency.

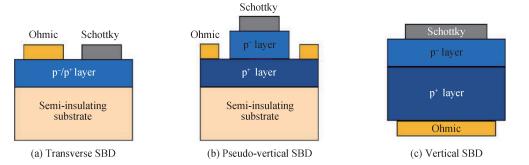

A Schottky diode is a type of power electronic device. It is a majority carrier device that operates by utilizing the Schottky barrier formed by the contact between metal and semiconductor. Diamond Schottky diodes are created by forming a p-type diamond film through boron doping and depositing metal on top to form a Schottky contact.

The quality of the contact between metal and p-type diamond semiconductors determines the performance of electronic devices, such as on-resistance, current, and breakdown voltage, and is crucial to their development and application. A Schottky diode is a unipolar device that utilizes both ohmic and Schottky contacts between metal and p-type diamond to achieve rectification. Diamond's inertness, wide bandgap, and high surface interface states make ohmic contact difficult to achieve. Therefore, ohmic contacts between metal and diamond are typically formed by depositing the metal on a heavily doped diamond surface to reduce the interface barrier width and increase the tunneling probability. Another method for creating ohmic contacts on diamond involves reacting the metal with diamond at the interface to form carbides, which lowers the barrier and exhibits ohmic properties. To achieve low ohmic contact resistance and realize high-current and low-power diamond power devices, research teams at home and abroad have extensively explored the properties of various metal-diamond contacts. The barrier height between titanium and p-type diamond is approximately -0.63 eV, making it a good ohmic contact.

Research has shown that high-temperature annealing can effectively improve ohmic contact performance. After annealing at 500°C in a vacuum atmosphere for 10 minutes, the contact resistance between Ti and diamond decreased from 2.9 × 10⁻³ Ω·cm² to 2.0 × 10⁻³ Ω·cm², a 30% improvement in ohmic contact. X-ray photoelectron spectroscopy (XPS) analysis indicates that the ohmic contact between Ti and diamond occurs due to a reaction at the interface, forming titanium carbide. To prevent surface contamination by metallic Ti, a protective layer of Au is often applied to the Ti layer. However, high-temperature annealing causes interdiffusion between Ti and Au, increasing the contact resistance and damaging the ohmic contact. Therefore, the currently widely used diamond ohmic contact is a three-layer Ti/Pt/Au metal layer. The Pt layer acts as a barrier, effectively preventing interdiffusion between Ti and Au during the annealing process. Metallic Ta forms TaC at the interface with p-type diamond, creating an ohmic contact. After annealing at 500°C, the TaC content increases, reducing the barrier height and contact resistance (from 1.52 × 10⁻³ to 7.19 × 10⁻⁵ Ω·cm²), improving the ohmic contact. Subsequently, metallic W was successfully applied as an ohmic contact electrode in a diamond Schottky diode. At 5 V, the device achieved a forward current of 16 A/cm², an on-resistance of 0.9 Ω·cm², a breakdown voltage of 640 V, and a breakdown field strength of 4.57 MV/cm².

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.Lightly B-doped diamonds offer excellent carrier mobility, making them ideal substrates for semiconductor applications. Heavily B-doped diamonds provide low electrical resistance, serving as conductive electrodes for ohmic contacts.Furthermore, it is an ideal material for the fabrication of high-temperature, high-power semiconductor components and can also be used in electrochemistry.Additionally, CSMH offers high-quality diamond wafer substrates (e.g., on Si or SiC), enabling customers to develop advanced semiconductor devices.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message