Pos:

Home KnowledgeTechnologyStudy on Electrical Properties of High-Quality Boron-Doped Single-Crystal DiamondDiamond semiconductors possess a series of excellent thermal, electrical, and mechanical properties, including high thermal conductivity (22 W/(cm·K)), an ultra-wide bandgap (5.5 eV), high breakdown field strength (10 MV/cm), high carrier mobility (electrons: 4,500 cm²/(V·s); holes: 3,800 cm²/(V·s)), and the highest Baliga figure of merit. These properties endow them with potential application prospects in high-temperature, high-frequency, and microwave power devices. Boron (B) acts as an acceptor impurity in diamond, with an activation energy of 0.37 eV. Through boron doping, p-type conductive single-crystal diamond materials can be obtained.

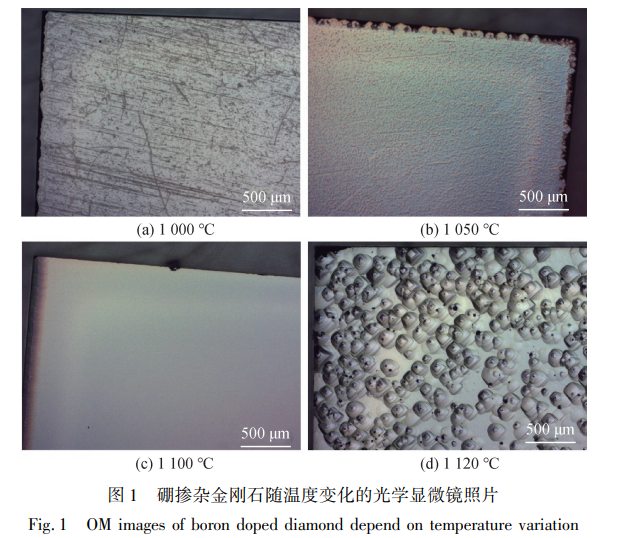

In the experiment, the boron-carbon ratio was controlled within the range of (20–2,400) × 10⁻⁶ (consistent with the samples used for testing doping concentration), while the growth temperature was fixed at 1,100 °C, the chamber pressure at 160 mbar, and the methane concentration at 8%. The Hall effect was employed to test the electrical properties of boron-doped diamond, such as conductivity type, carrier concentration, and mobility. All samples exhibited p-type conductivity. As can be seen from Figure 4, with the increase in the boron-carbon ratio, the carrier concentration increased accordingly, while the mobility showed an opposite trend. The reason for this is that the content of boron in diamond increases with the rise of the boron-carbon ratio. Due to the Coulomb interaction between the carriers activated by doping and the impurities, the probability of collision between carriers and impurities during the movement of carriers in the film increases, leading to a decrease in hole mobility. When the boron-carbon ratio was 20 × 10⁻⁶, the hole mobility of diamond was 207 cm²/(V·s) @ 1.6 × 10¹⁴ cm⁻³; in contrast, the mobility of heavily doped diamond films (with a doping concentration of 2.8 × 10²⁰ cm⁻³) was only approximately 10 cm²/(V·s) @ 4.8 × 10¹⁸ cm⁻³ (carrier concentration). It is evident that the boron-carbon ratio has a significant impact on the electrical properties of p-type diamond. Secondly, the growth temperature also affects the electrical properties of p-type doped diamond, as shown in Figure 5. In the experiment investigating the effect of temperature, the boron-carbon ratio was maintained at 20 × 10⁻⁶, the chamber pressure at 160 mbar, and the methane concentration at 8%. With the increase in growth temperature, the hole mobility gradually increased. As mentioned earlier, the surface of the boron-doped diamond film becomes smoother with the increase in growth temperature. However, when the temperature reached 1,120 °C, the mobility decreased sharply, which is caused by the diamond growth mechanism. The high-temperature environment intensifies the etching of the diamond surface by H₂ during the MPCVD reaction process, forming "pyramid"-shaped etching pits. That is, a large number of point defects are formed on the diamond surface, resulting in a decrease in film mobility.

This paper also studied the effect of methane concentration (CH₄/H₂) on the electrical properties of boron-doped diamond. The methane concentration ranged from 5% to 9.5%, while the boron-carbon ratio was maintained at 600 × 10⁻⁶, the chamber pressure at 160 mbar, and the growth temperature at 1,100 °C. The p-type mobility of diamond with a methane concentration of 5% was relatively low (119 cm²/(V·s)). The reason for this is that under the condition of low methane concentration, the growth rate of diamond is also relatively low, which leads to severe etching of the diamond surface by hydrogen atoms in the reaction gas and an increase in surface defects. When the methane concentration was increased to 7.7%, the mobility increased to 201 cm²/(V·s). With a further increase in methane concentration, the mobility decreased. At this point, the diamond grows in a step-growth mode, and the surface roughness of the film increases while the flatness decreases, resulting in a reduction in the carrier mobility. Combined with the relationship between growth rate and methane concentration shown in Figure 6(b), it can be seen that the growth rate reaches a peak when the methane concentration is 7.7%, and then decreases. For boron-doped diamond, it is necessary to find a balance between "growth rate" and "methane concentration" and precisely control the growth rate to meet the requirements of the epitaxial layer of diamond electronic devices.

Oxygen-assisted growth improves the crystallization quality and purity of boron-doped diamond, reduces the impurity scattering effect in the film, and thus significantly enhances the hole mobility. With the increase in oxygen concentration, the hole mobility values were 235 cm²/(V·s), 455 cm²/(V·s), 614 cm²/(V·s), and 278 cm²/(V·s) respectively, showing a trend of first increasing and then decreasing. The samples with oxygen contents of 0.4% and 1% had an uneven surface with many defects, and the rough surface caused scattering of carriers. In addition, the surfaces of the samples with oxygen contents of 0.6% and 0.8% both showed etching along a certain direction, but the etching of the latter was mainly concentrated at the edge of the sample, and its impact on carrier scattering was weaker than that of the former. Therefore, the sample with an oxygen content of 0.8% had the highest mobility, reaching 614 cm²/(V·s) @ 4.8 × 10¹⁵ cm⁻³ (carrier concentration). In general, the regulation of diamond doping via the MPCVD method is a complex growth kinetics issue. Due to the continuous incorporation and precipitation of impurity atoms, which dynamically change with the growth process parameters, the doping in the film becomes a dynamic process. Therefore, it is necessary to couple multiple process conditions to obtain p-type single-crystal diamond with excellent electrical properties.

High-quality boron-doped single-crystal diamond was prepared using the MPCVD method. By adjusting the boron-carbon ratio in the reaction gas, controllable doping process conditions with a boron doping concentration ranging from 10¹⁶ to 10²⁰ cm⁻³ were achieved, and the maximum doping concentration reached 2.8 × 10²⁰ cm⁻³. Subsequently, the influence of growth temperature and methane concentration on the electrical properties of p-type diamond was studied, and the phenomenon and mechanism of diamond surface etching under different conditions were analyzed. Finally, the oxygen-assisted growth process of boron-doped diamond was investigated, which effectively improved the mobility of p-type diamond. This study provides important experimental support for promoting the development of diamond-related electronic devices.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), and the surface roughness of diamond wafer a<1nm.It has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message