Pos:

Home KnowledgeTechnologyDiamond wafer for Resistives - The passive way to manage the heat and keep the VSWR low at high frequenciesTypically, RF resistors are made of a thin lossy strip of metal (TaN or NiCr) deposited on a dielectric substrate. For high power applications large amounts of heat must be handled and dissipated while ensuring operation temperatures below 125°C. The conflicting demands of minimizing the parasitic impedance of the resistors, through reducing resistor size and using low permittivity substrates, typically work against the requirement to maintain low operating temperatures with increasing power density.In this work it will be shown that using CVD diamond substrates provides an optimum solution that enables RF resistors to operate above 8 GHz while handing over 100 W of power.

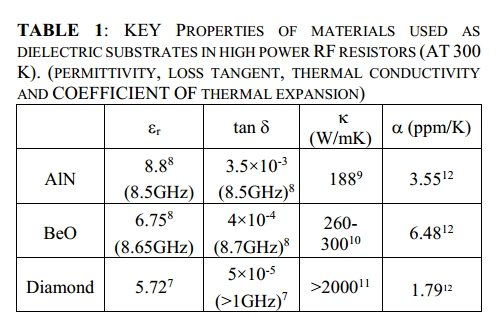

Table 1 summarizes the values of the key parameters affecting performance for the different high thermal conductivity substrates used in RF resistors. It is evident that AlN, with the highest permittivity and the lowest thermal conductivity will perform worse than BeO, with diamond excelling having the best combination of low permittivity and high thermal conductivity.

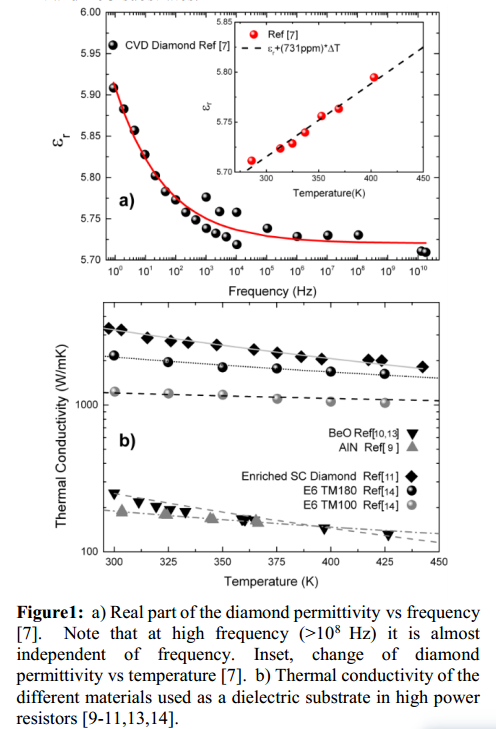

Diamond’s permittivity is ~15-35% lower than those of BeO and AlN respectively and is stable to changes in frequency and temperature, varying by only 5% from low frequencies up to tens of GHz, and only shifting by 730 ppm/°C from room temperature up to few hundreds of °C (Figure 1-a) .Stability of thermal conductivity as a function of temperature is also an important factor for successful operation of resistives at elevated frequencies. At 125°C the thermal conductivity for AlN and BeO are reduced by 30-40% from room temperature values (Figure 1-b). For the same span of temperature change the thermal conductivity of CVD diamond is changed by 10-15%.

Stability of RF and thermal properties enables a resistor made from purest single crystal diamond to potentially outperform AlN and BeO by factors of 10-15, as demonstrated through the ability of diamond to continue to dissipate higher level of the reflected power with increasing temperature.Figure 1-b shows the thermal conductivity of two polycrystalline diamond grades with bulk thermal conductivity of 1000 W/mK and 1800 W/mK, demonstrating significant improvement and stability over the thermal conductivities of AlN and BeO. In combination with its lowerpermittivity (Figure 1-a), CVD diamond resistives enable a 4-8x improvement in performance over that of resistives built on AlN and BeO substrates.

CSMH has been committed to the research and development and production of diamond materials. Now it has products such as diamond heat sink sheet,diamond wafer, diamond window to provide customers with a comprehensive thermal management solution.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message