IGBT is the core device of the NEV (new energy vehicle) drive motor, which plays a leading role in the efficiency, power density and reliability of automotive electric drive. So it is called the “heart of the car”. The temperature characteristic is an important index of IGBT module product's design and reliability evaluation. To greatly improve its power density, heat dissipation performance and long-term reliability, efficient heat dissipation scheme is particularly important.

The full name of IGBT is " Insulated Gate Bipolar Transistor ". It is a composite fully controlled voltage-driven power semiconductor device that is composed of BJT (bipolar junction transistor) and MOS (Metal-Oxide-Semiconductor), with self-turn-off characteristics. For EVs, IGBT directly controls the conversion of direct current and alternating current of the drive system, which determines the torque and maximum output power of the vehicle, etc. It can improve the efficiency and quality of electricity consumption and it is energy-efficient and environmental friendly.

NEVs tend to be high endurance and the heat dissipation of the power battery is increasing. It is necessary to introduce thermal conductivity materials with higher performance to solve the increasing heat dissipation problem. The industry's three major trends of "high performance, high integration, and high growth rate" mean higher demand for heat dissipation materials.

Taking hybrid electric vehicles as an example, specifications of IGBT module are generally 600V~1200V/200A~800A. The heat is concentrated because its own heat is large, and its motor, engine, etc. are in the front compartment of the car, the space is closed. If the temperature exceeds the IGBT junction temperature 125℃, it will destroy the module. Therefore, heat dissipation has always been the top priority in IGBT design.

As we all know, diamond is currently the highest thermal conductivity material. The thermal conductivity of diamond can reach 2000W/(m·k), which is 5 times that of copper and silver. Besides, it is a good insulator. So it is an ideal heat dissipation material for high-power laser devices, microwave devices, and highly integrated electronic devices. To meet the requirement of thermal conductivity between 1000 and 2000W/(m·k), diamond is the first and the only choice of heat sink material.

In addition, NEV has a large demand for super-hard tools, especially PCD tools. PCD tools have obvious advantages in the processing of aluminum alloy and composite materials. At present, NEVs are in a stage of rapid development, and the demand for super-hard tools will increase accordingly. Motor shell, shaft parts, battery boxes, differential and other parts in NEV need diamond tools processing.

The remaining driving range of EVs is difficult to predict accurately, and battery current sensors cannot accurately predict charge. The charging state has a margin of error of 10% because the battery current of electric vehicles can reach up to hundreds of amps, while the average current is only about 10 amps, which makes the battery use inefficient.

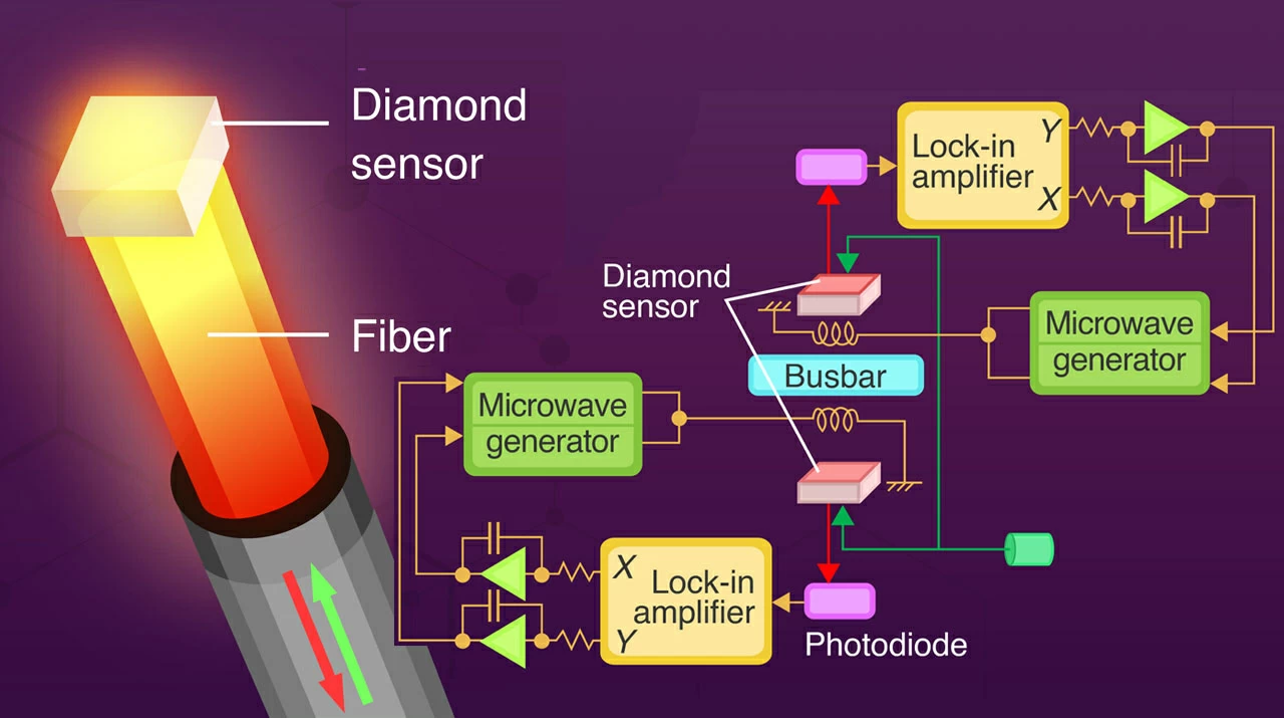

The diamond quantum sensor is applied to new energy vehicles. The current measurement range is ± 1,000A, the accuracy is 10 mA, which can effectively reduce the on-board battery capacity of electric vehicles, and improve power consumption by reducing weight, etc.

CSMH has been committed to the research and development and production of diamond materials. Now it has products such as diamond heat sink sheet, wafer grade diamond, diamond window to provide customers with a comprehensive thermal management solution.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message