Recent developments in X-ray imaging systems have led to innovative X-ray tube architectures for high resolution imaging based on submicron spot size. The window material is chosen to ensure two functions: it must exhibit an appropriate mechanical strength to be vacuum tight and must feature the highest thermal conductivity in order to lower the target temperature under operation. In addition, it must present a good X-ray transparency in order to reduce the flux loss.

Diamond is good for such applications as it is composed only of carbon (low Z material with high X-ray transparency) and it has the highest known thermal conductivity of all bulk materials (up to 2000 W/(m/K) for single crystal diamond at room temperature). It has recently emerged as viable solution for transmission type X-ray generators with higher thermal performances.

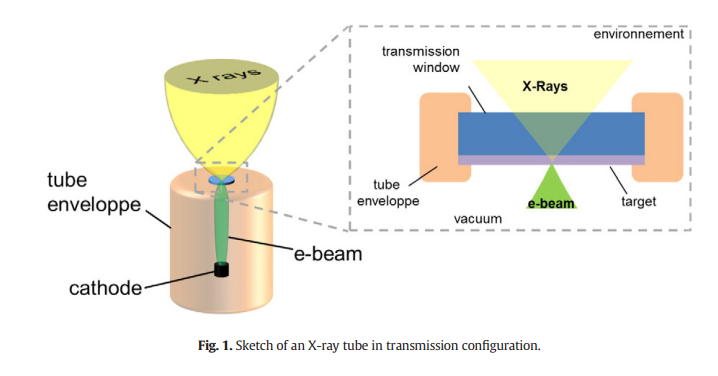

We considered a general problem based on a cylindrical window (as depicted in Fig. 1), of radius R and height H, which is the most common X-ray transmission tube window geometry. The membrane is considered to be edge-cooled by conduction only. The periphery of the cylinder is kept at a constant temperature by a perfect thermostat. A point heat source, dissipating a total power Q is placed at the center of the bottom face of the cylinder. The cylinder is made of perfect single crystal diamond with a constant thermal conductivity λ.

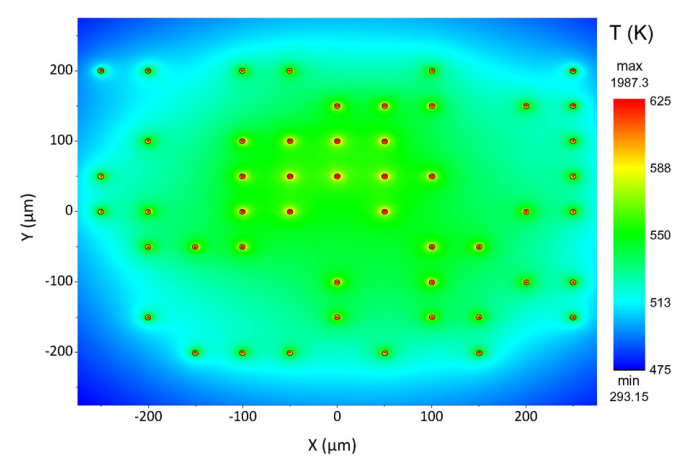

Recent developments have shown that imaging with an array of distributed X-ray sources is a promising alternative to standard techniques as it can give extremely good resolution and multiplexing capabilities. In such applications a patterned X-ray generation with small size sources is used resulting in a similar patterned heat generation. By using a linear superposition of the solution for several sources, distributed in a specific pattern, the overall temperature distribution is easily calculated.

For matters of comparison, a 3 × 3 matrix of 3.5 μm heat sources spaced by 50 μm has been modeled and the maximal temperature within each source is calculated in the model and the FEM simulation. The main advantage of such a simple model is to use it on more complex problems with a substantial gain on the computing time and resources. An example can be seen in figure below, where a complex pseudo-random matrix of sources is modeled and the surface temperature on the bottom side of the target is displayed. It is an application of coded aperture X-ray tube in which the patterned target acts as an irregular array of heat sources. Figure is obtained in few minutes with a standard computer while the complete FEM simulation of this system would take more time and resources.

Among the different applications aimed for this model, diamond windows for nanofocus X-ray tubes are of great importance. Undergoing developments on monocrystalline diamond windows will eventually lead to experimental comparison. It provides flexible and fast evaluation of the temperature with a controlled physical accuracy to bring a simpler vision to the field of thermal management in X-ray tubes.

Diamond is the ideal material for X-ray window as Diamond has the highest thermal conductivity to date and the widest spectral transmission range. CSMH can supply high quality diamond window, diamond heat sink, diamond wafer etc..

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message