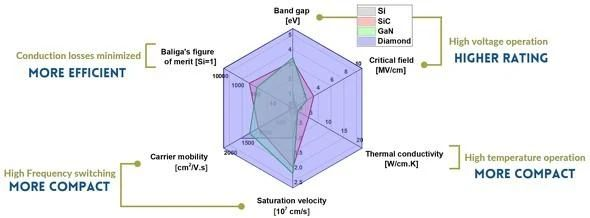

With the development of science and technology, silicon materials tend to reach physical limits in semiconductor production. It has been unable to meet the harsh conditions of some ultra-high specification electronic products, especially for RF chips, power devices in high frequency, high voltage, high power. At the same time, the chip manufacturing process continues to shrink, the key process is becoming more and more difficult, and the progress is getting slower and slower. For the efficient heat dissipation field of high power density devices such as chips, diamond with the highest thermal conductivity is regarded as the best "medicine" to cure the "fever".

Highly integrated chips generate a lot of heat but have uneven heat dissipation, causing them to reach excessively high temperatures, which reduces their performance, reliability and life. It’s important for highly integrated chips to solve the problem of "thermal death" caused by increasing power consumption.

In order to ensure the normal operation, good performance and service life of heat sink, it is necessary to consider the relevant physical and chemical properties such as thermal conductivity, thermal expansion coefficient, dielectric constant, resistivity, metallization and mechanical machinability. As the outstanding leader in the fourth generation of semiconductor materials, diamond has the highest thermal conductivity among natural substances known at present, stable chemical properties, good electrical insulation, small dielectric constant, high surface flatness and low density. By now, the most potential, efficient, long-life high thermal conductivity materials are carbon-based materials, mainly diamond.

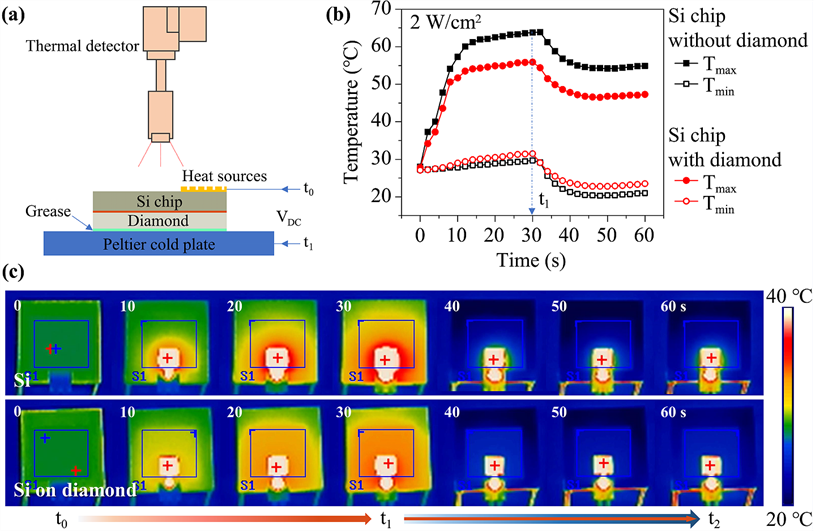

Experiments have shown that diamond has excellent thermal management ability under practical application conditions. In experiment, we placed a film heater on the surface of a silicon chip or silicon-diamond chip (27 × 28 mm2) to simulate a heat source (10 × 10 mm2) and placed the chip on a cooling plate, as shown in the figure. The heat source and cooling device are turned on at t0 and t1 respectively. Figure b reveals the change of surface temperature of Si chips and silicon-diamond chip with heating time at a heat source power of 2 W/cm2. After the cooling unit is turned on, the diamond radiator reduces the temperature of the hot spot by about 8 ° C, which achieves a cooling effect of 25 ° C at higher power (5 W/cm2).

CSMH has made breakthroughs in MPCVD diamond growth system, inch high thermal conductivity diamond production, diamond wafer and other production fields. It has become a technological innovator in the diamond industry, a promoter of industrial progress, and a popularizer of diamond technology.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message