Heating up neutron detection with CVD diamond wafer

Neutron-based measurements are important diagnostic tools across a range of industrial, security and research applications and the emergence of diamond-based neutron detectors has delivered significant capabilities as more sophisticated diagnostic tools develop.

In what ways diamond-based neutron detectors make a great contribution to neutron-based measurements?

1.Neutron diagnostics for fusion reactors

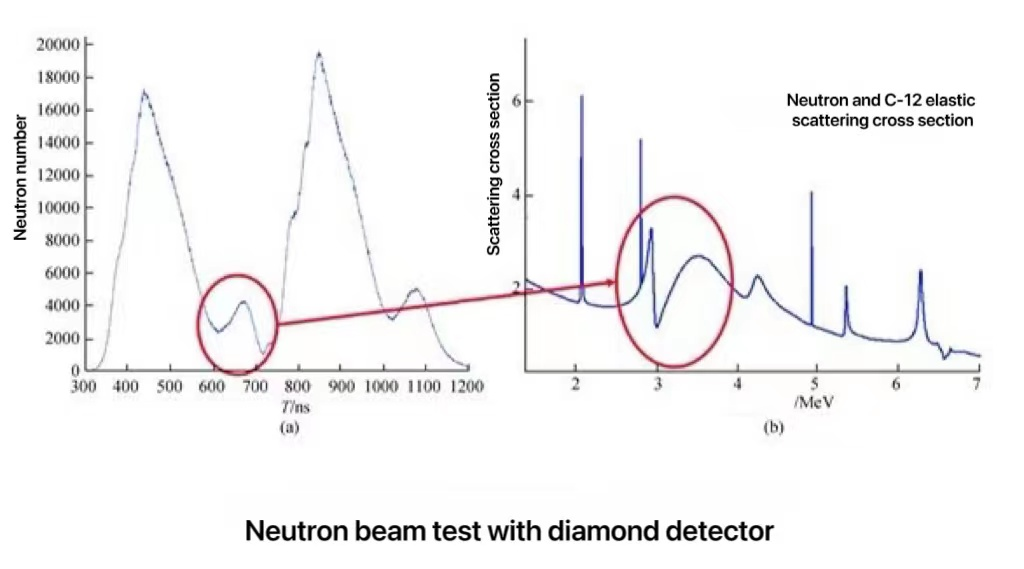

For deuterium-tritium (DT) plasma diagnostics in fusion reactors, such as ITER, diamond is an ideal sensor material. Its radiation hardness, combined with fast response, allow diamond detectors to directly identify fast neutrons and distinguish them from the background.

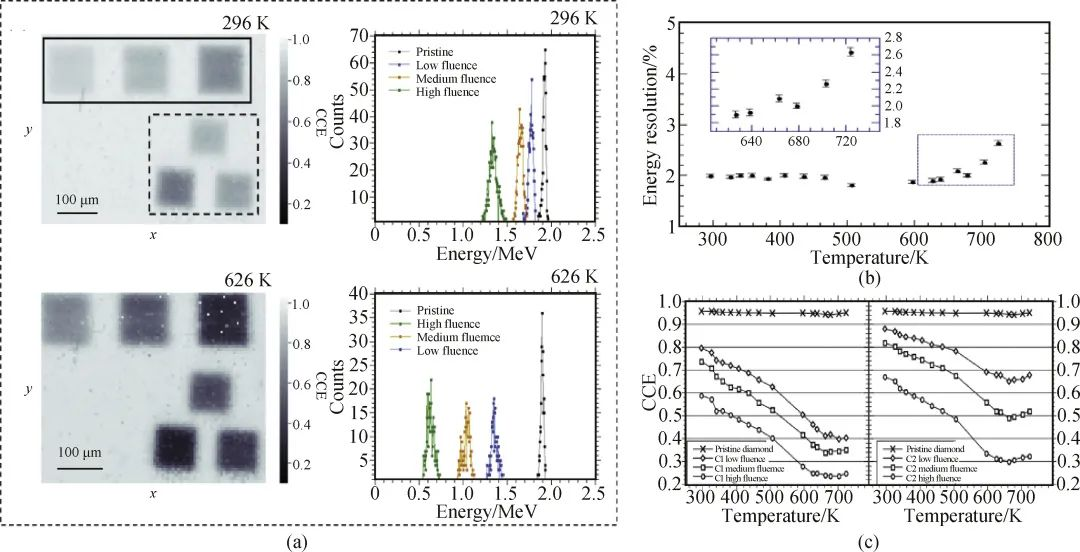

2.Temperature stability

Neutron generators often operate at high temperatures. Being insensitive to these conditions is critical for effective neutron diagnostic tools. Based on this requirement, diamond is an ideal material solution as it is proven to operate with constant performance up to 500 K.

3.Gamma ray rejection

Rejecting gamma radiation background is the key to effective neutron diagnostics as neutron environments are inherently characterised by significant levels of gamma radiation. Thanks to its low atomic number and, hence, intrinsic gamma insensitivity, diamond is the ideal sensor material for gamma ray rejection.

4.D-D plasma: the special case

In particular for D-D plasma diagnostics, with intrinsically low neutron energy deposition, the gamma insensitivity and high spectroscopic performance of single crystalline diamond sensors are crucial. Commercially available high-quality material allows the sensors to be configured in the most suitable way for these applications.

Diamond detectors are a compact, temperature insensitive, radiation hard and mechanically robust platform neutron diagnostic technology and can be tailored to meet the requirements of a wide range of experiments and industrial applications.

Diamond material has the characteristics of high carrier mobility, high carrier saturation drift rate and strong breakdown field. It is an ideal material for manufacturing high power, high temperature and high frequency devices. CSMH is a high-tech enterprise focusing on the research and development, production and sales of wide band-gap semiconductor materials and is committed to becoming the world's leading wide band-gap semiconductor materials company. The existing core products are diamond wafer (Ra < 1nm), CVD diamond heat sink (thermal conductivity up to 1000-2000W/m.k), diamond window,diamond and GaN heterointegration,AIN on diamond,etc.,which can be used in the production of neutron detector.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message