Pos:

Home KnowledgeTechnologyImprovement of interfacial thermal conductivity of diamond wafer / graphene heterostructuresWith the rapid development of artificial intelligence and micro-/nano-scale devices with precise chips, the accumulated heat in chips leads to their performance and reliability deterioration, which even incurs the chip to be destroyed and the whole system to damage . Hence, heat management and temperature control significantly affect the performance of microelectronic devices. Microcosmic heat transfer in this area has attracted attention, in which interfacial thermal transport dominates, and a large number of researches focused on heat transfer at the interface.

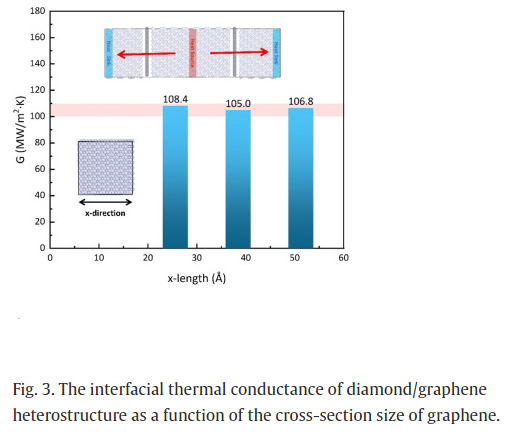

Materials with high thermal conductance can better facilitate the heat dissipation in microelectronic devices. Due to their strong bonding between atoms, carbon materials, especially two-dimensional graphene, possess ultra-high thermal conductivity. However, the internal phonon transmission of graphene is susceptible to surface or edge perturbation. That is, the in-plane thermal conductance would get obviously reduced once contacted with a substrate. Therefore, it is critical for graphene to select an ideal substrate. Although a lot of previous studies tried to find a solution for this issue, the results are discouraging as the thermal conductance across graphene/silicon, or metal interface frequently turned out to be within 20–85 MW/m2·K range, limiting the heat transfer in the interface .Nevertheless, these studies have not yet revealed the thermal transport for the diamond/graphene heterostructure interface. Various factors, either internal or external, would substantially affect the interfacial thermal conductance.

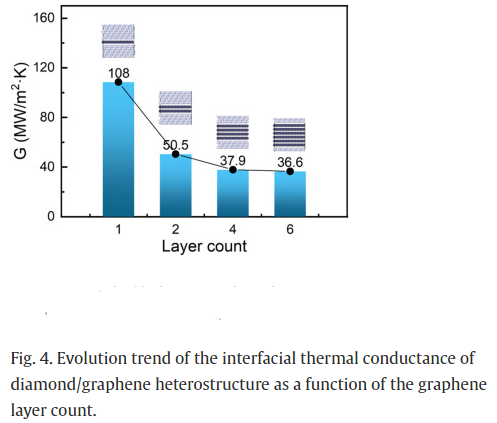

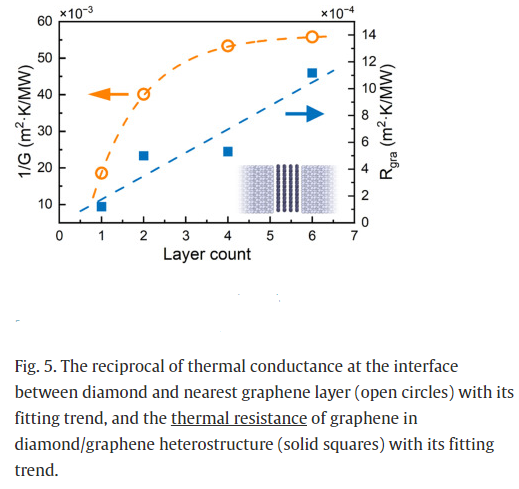

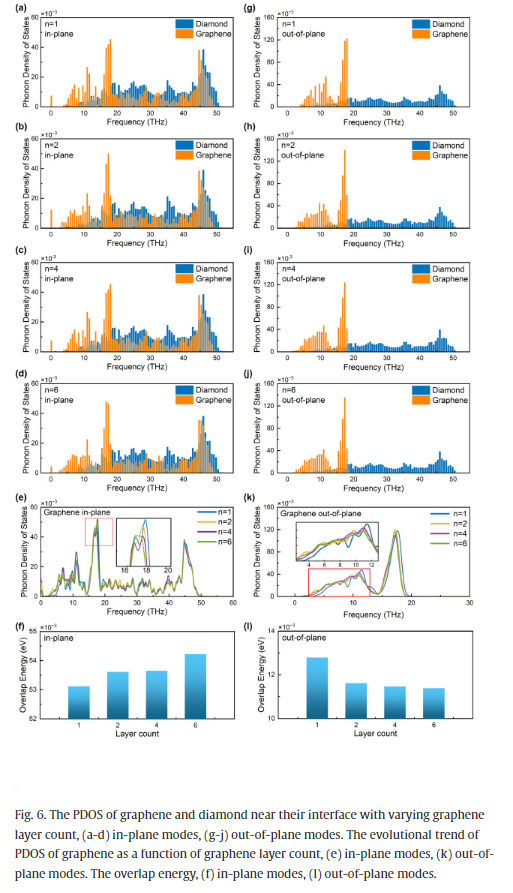

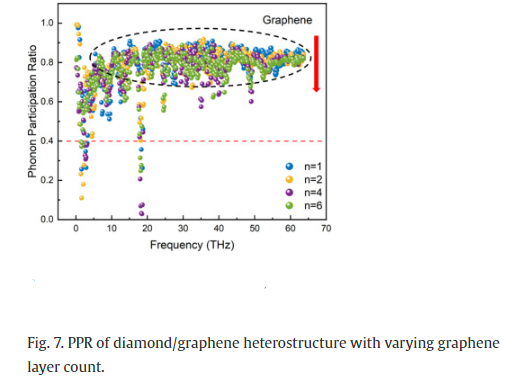

Recently, Professor Feng Yanhui of Beijing University of Science and Technology has made some progress in the study of interfacial thermal resistance between graphene and substrate. Based on non-equilibrium molecular dynamics ( NEMD ) simulation, the team studied the influencing factors of interfacial heat transport in diamond / graphene heterostructures, and the effects of graphene layers and temperature on the thermal conductivity of diamond / graphene heterostructures. The results show that the interfacial thermal conductivity of diamond / monolayer graphene heterostructure is at least twice that of diamond / multilayer graphene heterostructure. In addition, high temperature is also beneficial to the heat transport of diamond / graphene heterostructures. Due to the anisotropy of graphene, the team analyzed the in-plane and out-of-plane phonon density of states. The trend of overlap energy of out-of-plane phonon density of states is consistent with the interfacial thermal conductivity, which indicates that out-of-plane phonons have a greater impact on interfacial heat transfer. The increase of the temperature excites more high-frequency phonons, which promotes the phonon coupling of diamond and graphene. The research results well explain the reason for the increase of interfacial thermal conductivity at higher temperatures. The team provides guidance for improving the heat dissipation performance of micro-nano devices by analyzing the effects of key factors such as phonon state density ( PDOS ), overlap energy and phonon participation ratio ( PPR ) on interfacial thermal conductance.

Graphic analysis

-

-

CSMH focuses on the research and production of diamond wafers, and currently has diamond wafer, diamond heat sink , GaN on diamond ,AIN on diamond and other products, providing diamond thermal management solutions for our customers.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message