Pos:

Home KnowledgeTechnologyFluxless bonding technique of diamond wafer to copper using silver-indium multilayer structureEffective thermal management is crucial for efficient and reliable performance of optoelectronic and electronic devices. CVD diamond is among the best materials for efficient conduction and removal of the highly concentrated heat in the device.

Moreover, recently, the cost of diamond grown by chemical vapor deposition has been on a decline, making them more affordable . Diamond exhibits a very low coefficient of thermal expansion (1x10 /C). When it comes to bonding diamond to common metallic heat sinks such as copper with a much higher CTE value (16.5x10-6C), selection of bonding material and process becomes more demanding. These bonding techniques should result in a rigid yet ductile joint capable of managing the remarkable CTE mismatch between bonding components. Numerous thermal interface materials (TIM) and lead free solders are being used for purposes of making interconnection and heat dissipation in electronics packaging, however thermal resistance of lead free solders are roughly one order of magnitude lower than commercially available TIMs, making them more advantageous. Our research group has implemented Ag-In joints for bonding a wide array of materials during the past few decades . These joints can be achieved at low temperatures, while being capable of withstanding high operating temperatures.

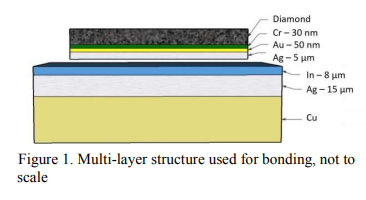

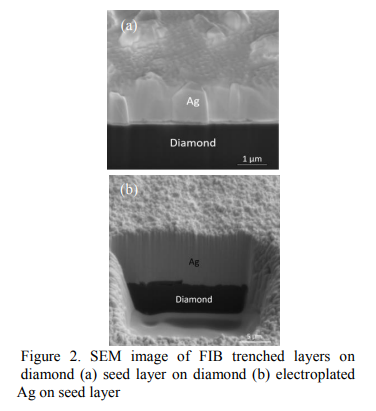

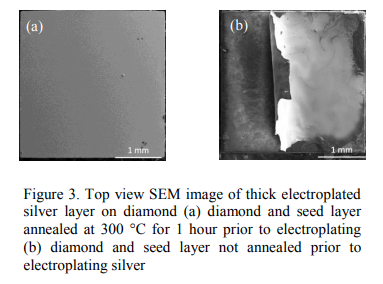

In this study we report on successful bonding of chemical vapor deposition (CVD) grown diamond to Cuusing a multi-layer Ag-In structure. To manage the large coefficient of thermal expansion (CTE) mismatch between copper and diamond, Ag-rich Ag-In solution is chosen as the final phase in joint. In our previous investigations, we have shown that Ag-In solid solution exhibit superior mechanical properties, such as low yield strength, high tensile strength. and large elongation. Here, we show that by using a fluxless process at vacuum, mechanically robust joints can be formed at 180·C between copper and diamond. Numerous samples that were bonded with proposed structure show acceptable shear strength and by performing a post bond annealing at 250 °C for 192 hours, we were able to achieve a joint almost fully composed of Ag solid solution with In, with significantly increased shear strength The deposited multi-layer structure is examined using scanning electron microscopy (SEM) coupled with focused ion beam (FIB prior to bonding. Following the bonding, samples are sheared and fracture surfaces are examined using energy dispersive X-ray spectroscopy (EDX). Our studies show that Cr/diamond interface, which is the metallization scheme on diamond is a weak interface in the bond design and as the joint becomes stronger by conversion of Ag-In intermetallic compounds into (Ag), more delamination occurs in the Cr/diamond interface. Additionally, it is reported that annealing the Cr/diamond interface can effectively improve its adhesion.

Graphic analysis

CSMH focuses on the research and production of diamond wafers, and currently has diamond wafer, diamond heat sink , GaN on diamond ,AIN on diamond and other products, providing diamond thermal management solutions for our customers.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message