Pos:

Home KnowledgeTechnologyEfficient heat dissipation perovskite lasers using a high-thermal-conductivity diamond wafer substrate

Semiconductor lasers based on solution-processed materials with simple fabrication, color tunability, large active areas, and excellent optoelectronic properties have promising applications in information, biomedicine, and computing for which standard inorganic materials are not ideally suited . Hence, organic semiconductor lasers have been extensively studied. Hampered by the lower mobilities and lower damage thresholds of organic semiconductors compared with their inorganic counterparts, electrically driven solution-processable lasers comprise a long-standing challenge in laser research. Lead halide perovskite semiconductors have significantly progressed in solution-processed optoelectronic devices. Long diffusion length, low trap density, and high charge carrier mobility of perovskites have turned these semiconductors into promising candidates for developing electrically driven solution processable lasers.

Perovskite lasers have rapidly achieved progress in developing continuous-wave excited lasing from a femtosecond pulse excited lasing, which is considered a critical step towards electrically excited lasing . After continuous-wave lasing at room temperature, the next goal is to realize electrically driven lasing . In commercially available electric injection lasers, traditional epitaxial grown single crystal semiconductors with both large thermal conductivity κ and high charge carrier mobility m usually exhibit small resistive heating under large current flow. While perovskites possess large and balanced charge carrier mobilities, they suffer from small κ values . The thermal conductivity of MAPbI3 is 1–3 W m−1 K−1, which is inferior to that of GaAs (50 W m−1 K−1) . Hence, heat converted from energy loss through nonradiative pathways cannot be effectively dissipated. This failure will increase the lasing threshold as carriers occupy a broader energy range at a higher temperature, diluting the population inversion of any given transition along with other problems such as degradation and heat-induced defects. The lowest electric excitation threshold of a distributed-feedback (DFB) perovskite laser would be as high as 24 mA cm−2 . Moreover, owing to high current injection in conventional perovskite light-emitting diode architectures used for laser devices, the external quantum efficiency would be significantly restricted under high current injection conditions owing to Joule heating. Hence, heat management is a bottleneck for developing perovskite-based electrically driven lasers.

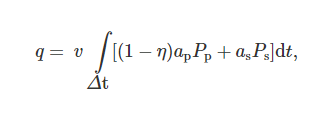

In a perovskite laser, temperature rising from absorptions of excitation light can be described by

|

where ρ, C, κ, and q are the density, specific heat, thermal conductivity, and heat source inside the device. For a pulsed pumped laser,

(2) (2) |

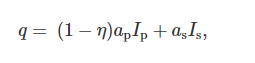

where Δt is the period used for the time integration of one laser pulse, v is the pulse repetition frequency, and η is the quantum efficiency of perovskites. ap and as are absorption coefficients of perovskites and the substrate, respectively. Pp and Ps are energy densities in the perovskite layer and substrate, respectively. For a continuous-wave pumped laser, q can be expressed as

(3) (3) |

where Ip and Is are light intensities in the perovskite layer and substrate, respectively. Normally, pump light propagates through the perovskite layer and substrate sequentially. According to the Beer-Lambert law, 90% of the pump light is absorbed by the perovskite layer as ap can be as high as 3 × 105 cm−1 . Therefore, Pp is much higher than Ps. To avoid further heat accumulation from the substrate, as should be much smaller than ap.

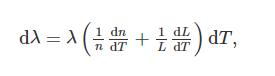

High-thermal-conductivity substrates are usually considered as solutions for tackling the above issue in perovskite lasers. Equation (1) shows that substrates with high thermal conductivities are capable of efficient heat dissipation for lasers with different injection mechanisms. The resonant wavelength λ of an optical microcavity is determined by λ = 2nL / p, where p is an integer, n is the refractive index, and L is the cavity length. Hence, the resonant wavelength of a whispering gallery mode (WGM) microcavity laser is only determined by the refractive index and cavity length. As both n and L are temperature sensitive, the wavelength shift induced by temperature is as follows:

(4) (4) |

where dn/ndT is the thermal optical coefficient, and dL/LdT is the thermal expansion coefficient. This characteristic makes monitoring the resonant wavelength shift of a laser ideal for temperature-sensing applications . For more efficient heat dissipation, a low-temperature continuous-wave perovskite laser was demonstrated using a sapphire substrate with high thermal conductivity (~25 W m−1 K−1). With improved heat dissipation, the demonstrated lasing shows a thermally induced peak wavelength shift of ~0.9 nm as the pump intensity increases from 17.5 to 18.4 kW cm−2 . Using a silicon substrate (~150 W m−1 K−1) and high-quality gain medium, even room-temperature continuous-wave lasing can be realized. Ascribed to the efficient heat management, the laser shows a thermally induced center wavelength shift of ~0.4 nm as the pump intensity increases from 2.5 to 22.5 W cm−2. To achieve optical confinement, we can introduce a low-refractive-index gap layer between the perovskite and silicon substrate. Using a YAG crystal-fiber scheme, thermal dissipation is improved by spreading heat over a crystal fiber that has high thermal conductivity (9.48 W m−1 K−1 ). Other high-thermal-conductivity materials, such as silicon carbide (490 W m−1 K−1), have also been reported to be used as substrates .

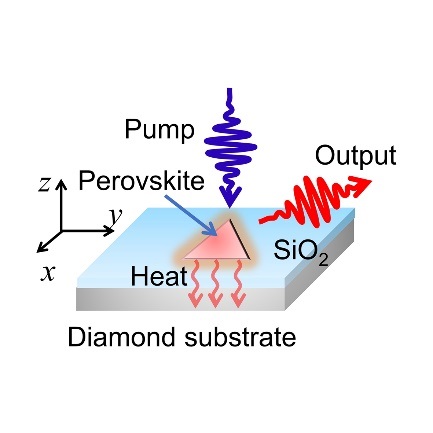

Among all natural materials, the diamond substrate has the highest thermal conductivity (2400 W m−1 K−1), which has already been widely applied as an ideal heat spreader for high-powered electronics . However, it has never been employed for developing high-performance perovskite lasers. Moreover, the lower refractive index of diamond (~2.40) compared with silicon is beneficial for realizing a lower effective refractive index for the substrate and may enable better optical confinement while improving heat dissipation . In this study, we report a perovskite laser with efficient heat dissipation based on a diamond substrate, which can successfully control the temperature elevation during optical pumping. We fabricated perovskite nanoplatelets through a chemical vapor deposition method on mica substrates. These nanoplatelets were then transfer-printed by thermal release tapes onto the diamond substrate covered with a low-refractive-index SiO2 gap layer . Benefitting from efficient thermal management and improved optical confinement, the perovskite laser exhibited a quality factor Q of ~1962 and lasing threshold of 52.19 μJ cm−2, with a pump density (P)-dependent temperature sensitivity as low as 0.56 ± 0.01 K cm2 μJ−1. The sensitivity is one to two orders of magnitude lower than values for previously reported perovskite nanowire lasers on glass substrates . This study facilitates the development of electrically driven perovskite lasers.

CSMH focuses on the research and production of diamond wafers, and currently has diamond wafer, diamond heat sink , GaN on diamond ,AIN on diamond and other products, providing diamond thermal management solutions for our customers.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message