With the continuous development and progress of society, electronic information technology, like other electronic related fields, requires more and more data transmission, especially mobile phones, satellite broadcasing and wireless network systems. High-frequency surface acoustic wave (SAW) equipment is a target among the equipment that can help meet this requirement.

Compared with traditional vibration film materials such as carbon fiber film, ceramic film, beryllium film, etc., they do not have the low density of diamond film, good acoustic damping characteristics of diamond film, low specific gravity, high fidelity, and excellent high-frequency response characteristics. In addition, the crystal boundary of diamond film can cause internal loss. Compared with other materials, the loudspeaker vibration film made of diamond film is better. At the same time, because of the high elastic modulus of diamond, it can be made into SAW (surface acoustic wave) devices. The use of dielectric materials with high sound velocity is one of the effective ways to improve the working frequency of the device. The material with the fastest sound velocity in known materials is diamond (11000 meters/second), which can greatly improve the working frequency of SAW, thus converting the radio frequency signal into mechanical vibration, This has a broad application prospect in satellite mobile phone communication.

Advantages of satellite mobile phone made of diamond film:

1. The fastest sound propagation rate;

2. High elastic modulus;

3. Low mass density;

4. High thermal conductivity, clear and accurate sound positioning;

5. High fidelity;

6. Excellent high-frequency response characteristics;

7. Maximum hardness;

8. Good acoustic damping characteristics;

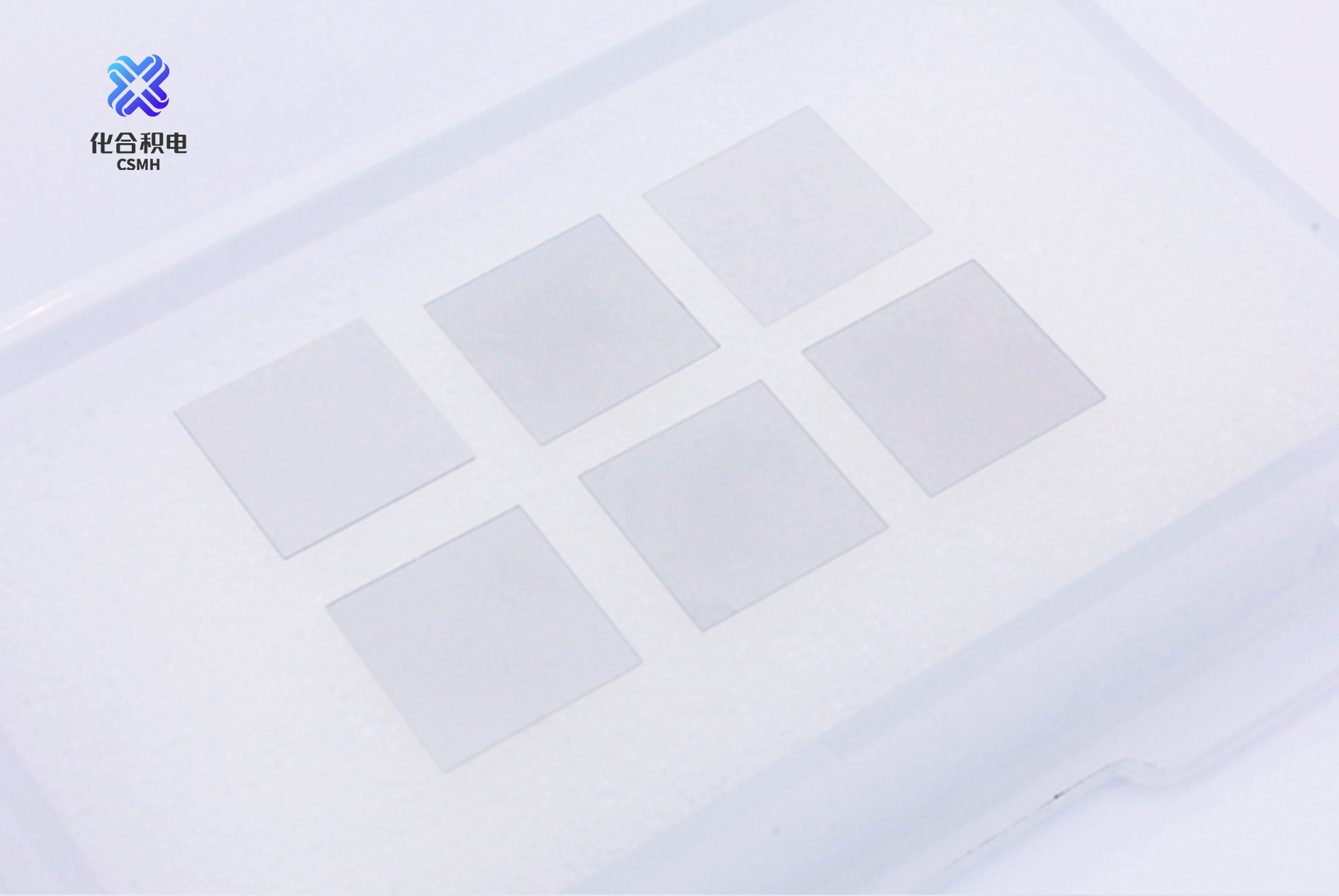

CSMH focuses on the research, development and production of diamond, and has the ability to design MPCVD equipment. It is the first in China to master the core technology of preparing high-quality diamond film by MPCVD and realize mass production. It also creates an efficient and precise processing method of diamond atomic surface based on plasma assisted polishing. Wafer grade diamond Ra<1nm, thermal conductivity of diamond heat sink 1000-2000W/m.k, and GaN on diamond, Diamond on GaN Diamond-based aluminum nitride and other products, the quality of which has reached the world-class level. At present, the products are widely used in 5G base stations, lasers, new energy vehicles, new energy photovoltaic, aerospace, defense and military industries and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message