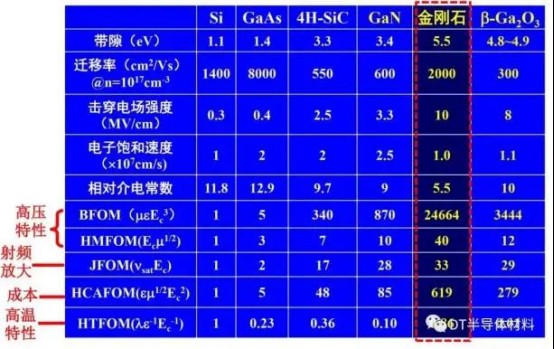

Diamond is an ultra-wide band gap semiconductor material with a band gap of 5.5 eV, which is larger than GaN, SiC and other wide band gap semiconductor materials. As shown in the following table, the band gap of diamond is 5 times that of Si; The carrier mobility of diamond is also 3 times that of Si material. Theoretically, the carrier mobility of diamond is more than 2 times higher than that of existing wide band gap semiconductor materials (GaN, SiC). Meanwhile, diamond has very low intrinsic carrier concentration at room temperature. Moreover, in addition to the highest hardness, diamond also has the highest thermal conductivity among semiconductor materials, which is 7.5 times that of AlN. Based on multiple excellent performance parameters such as high pressure resistance, high radio frequency, low cost and high temperature resistance, diamond is regarded as the most promising material for the preparation of the next generation of high power, high frequency, high temperature and low power loss electronic devices, and is known as the "ultimate semiconductor" in the industry.

FIG.1 Comparison of characteristics of several semiconductors

Because of the properties of diamond, from materials to devices, diamond research and development has made remarkable progress in recent years. A long time ago, people began to develop diamond research. In the 1970s, American scientists developed the method of high temperature and high pressure (HPHT) to grow small bulk diamond single crystal, which started the upsurge of diamond research. In recent years, with the advent of the post-Moore era, people's research and development investment in the field of new materials keeps increasing, which also accelerates the development of ultra-wide band gap semiconductor materials such as diamond. Both in material preparation and devices have significant new technological breakthroughs.

In terms of materials and preparation:

Diamond preparation methods are mainly divided into high temperature and high pressure method (HPHT) and plasma chemical vapor deposition (PCVD).

High Temperature High Pressure (HPHT) method belongs to thermodynamic equilibrium growth. According to the carbon phase diagram, it can be seen that the stable phase under high pressure is diamond, which transforms graphite into diamond by applying external pressure and temperature. During the growth process, the carbon source is usually graphite. Under the catalytic action of metal melt, the carbon source is kept under constant ultra-high temperature and high pressure conditions (usually the pressure is about 5.4 GPa and the temperature is about 1400 ℃) through the catalyst. The carbon source is transported to the surface of the crystal seed in the low temperature region by the metal catalyst and continuously deposited to grow into cultivated diamonds.

Chemical Vapor Deposition (CVD) is a process that utilizes gas precursors to undergo chemical reactions on specific conditions and substrate to deposit and form the required thin film materials. In the preparation of monocrystalline diamond materials, methane and hydrogen are usually used as precursors. Under the conditions of high temperature (about 1000 ℃) and low pressure in semi-vacuum, monocrystalline diamond is used as the substrate to grow in the way of gas epitaxy. Since the stable phase of carbon under atmospheric pressure is graphite phase, an endless supply of plasma hydrogen atoms is needed to surround methane (CH4) and decomposition of sp3 structure in the process of CVD diamond growth, and the activated carbon atoms are linked to the diamond seed crystal by controlling deposition growth conditions.

In general, compared with HPHT method and other PCVD methods, MPCVD has the advantages of non-electrode discharge, no pollution and strong epitaxial controllability, and has more obvious advantages in the preparation and doping of large-size and high-purity diamond. It is the preferred method for the preparation of diamond with high quality and multi-field applications. In addition, compared with polycrystalline diamond, single crystal diamond (SCD) without grain boundary restriction has better optical and electrical properties. It has outstanding application effect in frontier scientific and technological fields such as quantum communication/computational radiation detector, cold cathode field emission display, semiconductor laser, multi-dimensional integrated circuit of supercomputer CPU chip and thermal conduction support rod of microwave traveling wave tube of military high power radar. The premise is to prepare large size and high quality SCD. As a wafer, diamond must be at least 2 inches in size. At present, the main techniques for preparing large-size diamond and wafer are homogeneous epitaxy growth, Mosaic wafer fabrication and heteroepitaxy growth. The homogenous epitaxy of single crystal wafer has a low defect density, and the maximum size can reach 1 inch. And diamond heteroepitaxy wafers can reach up to 4 inches. In the case of low-cost heteroepitaxial CVD, the development and application of diamond polycrystalline films has been active, with wafers up to 8 in., which have been used as thermal conductivity substrates for the next generation of GaN power electronics. For this reason, diamond materials are required to develop in the direction of large size, low defect, low resistivity and high thermal conductivity.

In the research of diamond devices:

1. Diamond doping problem

For diamond semiconductor devices, doping of diamond material is the basic technology to form power devices, and has always been the focus of research. The biggest problem in the commercialization of diamond semiconductor is that the high efficiency doping of diamond has not been solved, and it is easy to manufacture P-type transistors and difficult to manufacture N-type transistors. Because of the dense structure of diamond and small gap. Traditional element doping techniques usually cause serious lattice distortion, deep level doping and difficult carrier activation at room temperature.

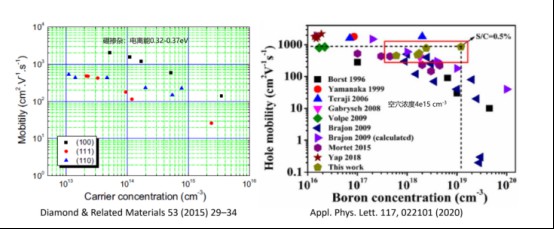

At present, the P-type doping technology of diamond is relatively mature, and the main doping is boron atom. For P-type diamonds, boron impurities can easily be incorporated into natural and MPCVD diamonds. There is no crystal orientation problem, but the activation efficiency of boron is less than 0.1% at room temperature. The doping concentration of boron in diamond and the mobility are the relationship between one and the other. Too large doping concentration often leads to a rapid decline in the mobility. When the boron doping concentration is 1019 cm-3, the mobility will be reduced to less than 100 cm2·V-1·s-1. According to the position of C atom of diamond (covalent radius 0.077 nm) in the periodic table, the nearest is nitrogen (N) atom (0.075 nm), which makes it also a favorable candidate for diamond N-type doping. However, due to the associated Jahn-Teller effect, the local lattice of the N atom of C atom in the doped replacement diamond is skewed, and the N atom deviates from the replacement position. The doping energy level is very deep (1.7eV), which makes it difficult to conduct electricity at room temperature.

FIG. 2 Ionization energy and hole concentration of boron doped diamond

2. Application progress of diamond devices

With the rapid development of 5G communication era, the application of single crystal diamond materials in semiconductor and high-frequency power devices is increasingly prominent. Diamond single crystal and its products are an important material basis for the implementation of major national strategies such as ultra-precision processing and smart power grid and the upgrading of industrial clusters such as intelligent manufacturing and 5G communication. Breakthroughs and industrialization of related technologies are of great significance for the independent security of intelligent manufacturing and big data industry.

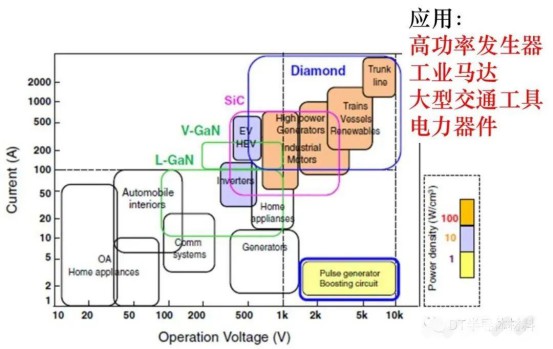

Diamond can be used as active device material to make field effect tube, power switch and other devices, and can also be used as passive device material to make Schottky diode. Because diamond has high thermal conductivity and extremely high charge mobility, its semiconductor devices can be applied in high frequency, high power, high voltage and other harsh environment, has a huge application prospect.

FIG. 3 Schematic diagram of diamond semiconductor application field

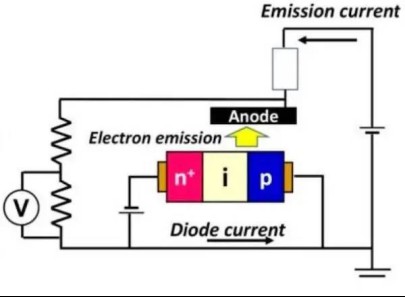

(1) One area where diamond is superior to other materials such as SiC is its high dielectric breakdown strength and high critical electric field. This advantage may be beneficial in reducing the on-going resistance of the Schottky barrier diode (SBD) breakdown voltage capability in high power engineering equipment and applications.

FIG. 4 An example of vacuum power switching using a diamond PiN diode in an emission current

(2) In the field of power electronics, the direction of high breakdown voltage, high breakdown field, high temperature operation, low on-resistance, high switching rate and normally off devices. Diamond transistors are dominated by various kinds of FETs, including metal semiconductor field effect transistor (MESFET), MOSFET and JFET, and their channels are of two kinds: two-dimensional hole gas on the surface of diamond hydrogen terminal and P-type doping layer. With the development of N-type doping materials, bipolar diamond devices have begun to appear, and recently heterojunction bipolar transistors have been developed. In the field of microwave electronics, hydrogen terminal FET is mainly used, and it is developing towards high fT /fmax and high power density.

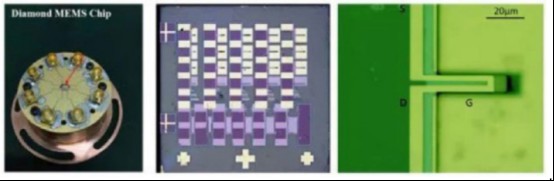

FIG. 5 Schematic diagram of diamond MEMS chip and diamond cantilever integrated into the chip

CSMH specializes in the research and production of diamond. Its core products are diamond wafer, diamond hot sink, diamond-based gallium nitride epitaxial sheet and aluminum nitride film. The quality of its products has reached the world's leading level. The thermal conductivity of diamond heat sink sheet can reach 1000-2000W/m.k, and the surface roughness of wafer diamond growth surface Ra < 1 nm. The products are widely used in 5G base stations, lasers, new energy vehicles, new energy photovoltaic and other fields. High-power semiconductor devices using diamond heat sink have been used in optical communication, RF power amplifier, laser diode, power transistor, electronic packaging materials and other fields are also used. We will always uphold the concept of customer first, continuous to provide customers with the best products and services.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message