Currently, a system-level comparison between diamond and silicon carbide (SiC) power devices has been proposed, demonstrating the advantages of diamond semiconductors in power electronics applications.

Actual diamond power devices were fabricated and characterised (DC, AC smallsignal, large-signal power switching in a buck converter). Models of the diamond devices are discussed based on the experimental data, and the expected performances of the future diamond semiconductors in power converters are presented. These performances are compared to the commercialised SiC Schottky diodes for a given application. Our analysis shows that diamond devices can be used to increase the performance of power converters, especially at high temperatures. We demonstrate that for a junction temperature of 450 K, diamond semiconductors can divide the semiconductor losses and heatsink volume by three, in comparison with SiC devices. We also demonstrate that the switching frequency with diamond devices can be five times higher than with SiC devices, with lower total semiconductor losses and smaller heatsink in diamond-based power converters. This system-level analysis clearly shows the future improvements in the efficiency and power densities of power converters thanks to diamond power devices. The need for management of the specific junction temperature, which is required in order to exploit all of the properties of diamonds, is demonstrated and discussed .

Wide bandgap (WBG) semiconductors have been used in recent years to improve the performances of power electronics converters. Materials such as silicon carbide (SiC) or gallium nitride (GaN) allow power converters to operate at higher voltages, higher temperatures, and higher switching frequencies than silicon (Si). These benefits are due to the superiorities of the WBG materials. Among WBG semiconductors, diamond is the most promising material for power electronics applications. Whereas the experimental benefits of SiC and GaN devices in actual power converters have been widely demonstrated, the system-level benefits of diamond power devices have not yet been clearly described.

As a comparison is presented between the performances of diamond and SiC power devices in order to highlight the benefits of diamond in the power electronics community. The characteristics of the diamond device are based on analytical models and were compared to a commercial SiC Schottky diode. The comparisons were performed on the estimated total 34 semiconductor losses in a 900 V/10 A buck converter, and the volume of the required heatsink as a function of the junction temperature during steady-state operation of the converted was determined. It was shown that by using diamond semiconductors both the heatsink volume and the power device losses could be reduced or the switching frequency could be increased with a smaller heatsink, allowing for an increase in the efficiency and power density of the converters. However, due to the incomplete ionisation of the diamond dopants at RT, the diamond devices have to operate at high temperature to surpass the performance of SiC components. Nevertheless, power converters made of diamond devices can operate at RT and below from start-up. The performances of the converter will be improved as the diamond devices warm up due to their operational losses. Even if these results are based on several hypotheses, it shows that the precise design of converters and temperature management are needed to exploit the full benefits of diamond semiconductors in power converters. It shows that special integration methods and special temperature managements have to be developed for the realisation of future high-efficiency power converters based on diamond devices.

Compound Semiconductor Manufacturing (Xiamen) Co.,Ltd is a wide bandgap Semiconductor Material company invested from the Korea, China and Singapore, registered in the city of Xiamen, China. We are equipped with advanced semiconductor manufacturing tools including MPCVD, MOCVD, LPCVD, HVPE and high temperature PVD.

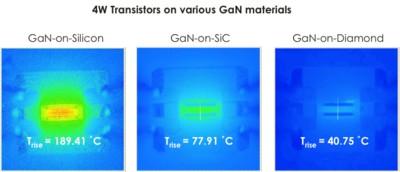

Products including: high quality diamond wafer, diamond heat sink, GaN & Diamond wafer and PVD AlN template etc.

We have strong R&D team and actively collaborate with best research group around the world. Currently, we are providing the thermal grade polycrystalline diamond, which can be used as an effective heat sink aims to solve the heat issue in temperature sensitive device, such as power devices, lasers and avalanche photodiodes etc. We also provides wafer scale polished diamond with sub-nanometer RMS surface roughness, which might be suitable for the integration of GaN, GaO and AlN epilayers and devices on Diamond via direct bonding or heteoepitaxy.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message