Hardness against environment Diamond radiation detector is promising for application in harsh environments because of its excellent chemical stability, operation at high temperatures, and radiation hardness. Historically, diamond has been used to measure neutrons and neutral particles generated from nuclear fusion reactors. In recent years, due to the accident at the Fukushima Daiichi Nuclear Power Plant, there has been a trend to use diamond for decommissioning and radiation monitoring in harsh environments. Today, high temperature operation and radiation resistance will be discussed.

High temperature operation In a semiconductor, the intrinsic carrier density de creases as the bandgap increases, resulting in a smaller leakage current. This makes it possible to operate the diodes at high temperatures.

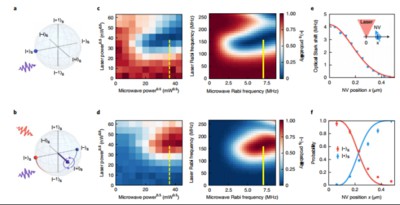

Diamond, an ultra-wide gap semiconductor, is expected to operate at even higher temperatures than conventional wide gap semiconductor materials such as SiC. Diamond Schottky barrier diodes have been reported to operate stably at 400 °C for 1500 h. Diamond radiation detectors have been confirmed to operate at temperatures between 150 °C and 500 °C. It shows alpha-particle induced charge measurements of diamond radiation detectors from 298 to 573 K.

Though the detector presents good CCE at 300 °C, the degradation of CCE and energy resolution were observed due to the decrease in mobility and carrier lifetime with increasing temperature. SiC radiation detector has also been reported to operate at high temperatures, however, degradation of energy resolution due to increased leakage current has been reported at 300 °C. CCE measurements induced by incident 5.486 MeV alpha-particles of 241Am up to 573 K for the detector of Diamond Detector Ltd., (DDL). The CCE and the resolution of DDL diamond indicated 98.2% and 1.6% of holes and 97.9% and 1.1% of electrons at room temperature. At 523 K, the CCE and the resolution of DDL diamond indicated 98.2% and 2.1% of holes and 96.7% and 2.2% of electrons. At temperatures higher than 573 K, only electron spectra were detected. The values were CCE 93.8%, with 2.6% resolution. At 623 K, no detection was possible.

CSMH focuses on the R&D and production of diamond wafers, and has created an efficient and precise machining method for diamond atomic-level surfaces based on plasma-assisted polishing, diamond wafer Ra<1nm, diamond heat sink thermal conductivity 1000-2000W/m.k, and GaN on diamond, Diamond on GaN, diamond-based aluminum nitride and other products. We will keep pursuing the innovation-driven development strategy in the future, offering our customers products of high quality and reliable performance while contributing the rapid development of the global semiconductor industry.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message