According to statistics, GaN power device failures caused by heat concentration account for 55% of the total failure rate. Whenever a power device is broken or the device is burned out due to heat, have you ever thought about changing a new heat dissipation material instead of continuing to spend a lot of money to repair the device that cannot continue to operate due to failure? So, what new heat dissipation material can make you start without loss? Friends, please take a look, the diamond wafer will surprise you!

Diamond, which has been discovered by mankind for more than 2,000 years, is known as the "king of gemstones", but its value is much more than that. It has wide band gap, high thermal conductivity, high breakdown field strength, high carrier mobility, high temperature resistance, acid and alkali resistance, corrosion resistance, radiation resistance, and superior performance makes it play an important role in high power, high frequency, high temperature and other fields. As the name suggests, diamond can certainly be applied to GaN power devices.

At present, due to the limited thermal conductivity of GaN device substrates and epitaxial materials, traditional package-level thermal technology cannot effectively improve thermal performance when the device is running at high power, so it is necessary to improve the thermal management capabilities of GaN devices from within the device.

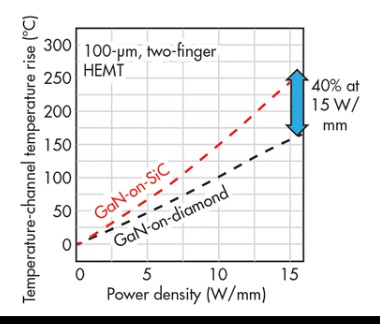

Experimental studies have shown that substrates such as SiC and diamond integrated into GaN can improve thermal management. For the same power density, GaN on diamond can reduce the channel temperature by at least 40% compared to GaN-on-SiC, which will increase the device life by a factor of approximately 10. Experimental studies have shown that substrates such as SiC and diamond integrated into GaN can improve thermal management. For the same power density, GaN on diamond can reduce the channel temperature by at least 40% compared to GaN-on-SiC, which will increase the device life by a factor of approximately 10.

Figure 1 Infrared image of a GaN transistor running on a different substrate dissipating the same power

An infrared image of a GaN transistor running on a different substrate dissipating the same power shows that GaN-on-Diamond is the one with the lowest operating temperature because the temperature rise between the substrate and the gate is reduced and can be used to operate at hotter ambient temperatures. Another study shows that the combination of diamond and gallium nitride (GaN) at room temperature can withstand heat treatment of 1000 ° C, which greatly improves GaN HEMT thermal management, thereby reducing the operating temperature of the device, so it is an ideal material for GaN HEMT high-temperature manufacturing process.

At present, Diamond & GaN combines three ways:

1. After GaN/diamond bonding GaN HEMT preparation is completed, transfer bonding to diamond substrate.

2. Diamond on GaN grows diamond on GaN HEMT structure.

3. GaN on Diamond grows GaN structure directly on diamond substrate.

CSMH is a high-tech enterprise focusing on the research and development and production of third-generation (wide bandgap band) semiconductor substrate materials and devices, and is committed to becoming the world's leading wide bandgap semiconductor materials and devices company. We have always adhered to the concept of customer first, to provide customers with the best products and services. At present, the company has realized the large-scale production of diamond and aluminum nitride related products, the existing diamond wafer Ra<1nm, diamond thermal imposition sheet thermal conductivity 1000-2000W/m.k, and GaN on diamond, Diamond on GaN, diamond-based aluminum nitride and other products. And has been widely used in 5G base stations, lasers, new energy vehicles, new energy photovoltaics and other fields.Here, we will provide you with the most comprehensive diamond thermal management program.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message