With the continuous development of China's aerospace industry, the detection of the universe has reached an unprecedented height, so the performance requirements for the detector are getting higher and higher. For traditional Si, Ge and other semiconductor detectors, due to the small width of the material bandgap band, in the harsh environment of high-intensity radiation, the lattice is susceptible to radiation damage, so that the doping concentration changes, the leakage current and capacitance of the detector increase, the charge collection efficiency is significantly reduced, can not meet the high energy and dose of particles and rays sensitive, reliable detection, and for fast neutron monitoring in the field of nuclear technology, the detector needs to have the characteristics of radiation resistance, fast response and high temperature resistance. Therefore, a new type of high-performance detector is urgently needed to deal with this problem.

Diamond wafer has a large band free width (5.5 eV), high resistivity (> 1010 Ω/cm), a small dielectric constant (5.7), a high breakdown voltage (107V/cm), a high carrier mobility (electrons 4 500cm2/Vs, a hole 3800 cm2/Vs), a very high thermal conductivity (up to 2200W/m·K), and can suppress leakage current without forming a pn junction, thus ensuring that the diamond detector can work reliably directly in high temperatures and harsh environments It can withstand high operating voltage (leakage current of less than 40 pA/cm2 at 1000V applied voltage), strong radiation resistance (low atomic number and reinforcement bond make it have strong resistance to radiation damage), high charge collection efficiency, fast time response (charge collection time is 4 times faster than Si), and high signal-to-noise ratio (72:1), so it is considered the most promising detector material.

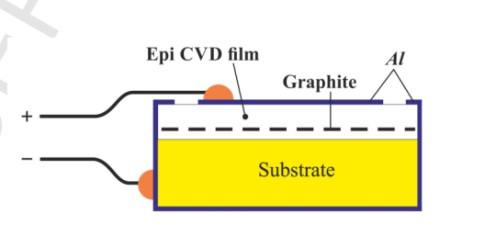

Figure 1 Simplified view of CVD diamond detector

In extremely harsh environments, the self-supporting CVD diamond window gauge used can detect the characteristic X-spectrum lines emitted by light elements such as boron, carbon, nitrogen, oxygen and fluorine that cannot be detected by the beryllium window, reducing the working risk factor.

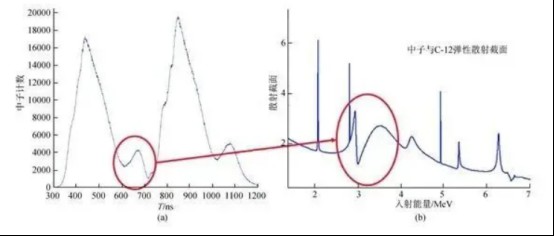

A series of experiments were conducted on whether diamond could be applied to nuclear detection: the single crystal diamond material prepared by the best process was polished and encapsulated to become a detector, and a neutron beam test was carried out on the Chinese spallation neutron source located in Dongguan, Guangdong Province. Spallation neutron source uses proton target to produce neutrons, every 40 ms accelerator will hit two proton beams with a time interval of 410 ns to bombard the tungsten target, generating neutron pulses, neutron pulses have the same time structure as proton pulses, you can take the proton target time as the time starting point, measure the flight time of the neutrons, and thus obtain accurate neutron energy information.

Figure 2 Neutron beam test of diamond detector

The two-bundle cluster structure with a time interval of 410 ns can be clearly seen. In addition, behind each main pulse can be seen a relatively small pulse with a neutron energy of about 3 MeV. The reason for its formation is due to the high scattering cross section of the C-12 nucleus to the 3 MeV neutrons (as shown in Figure 8(b)). The reaction cross-section is typical of (n, n) elastic scattering, which is not sufficient to further excite inelastic scattering due to the neutron energy of 3 MeV . The results of the neutron time-of-flight spectrum show that the current diamond detector has a high detection efficiency for the neutrons of this energy, thereby producing a formant structure on the time-of-flight spectrum.

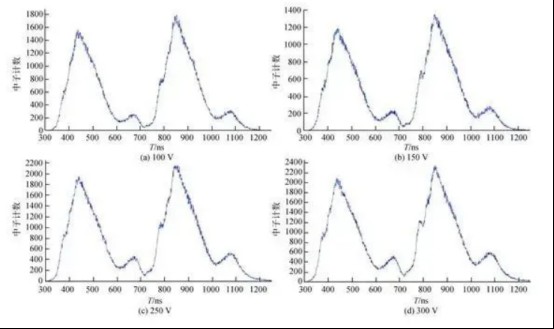

In addition, the effects of different biases on the neutron time-of-flight spectrum were also studied, as shown in Figure 3

Figure 3 Plot of the effect of detector bias on the neutron time-of-flight spectrum

In the process of increasing bias pressure, due to the continuous improvement of the charge collection efficiency of the detector, the neutron detection efficiency and the counting rate will be significantly improved, but there is no significant change in the neutron time-of-flight spectrum, indicating that the measurement of the neutron time-of-flight spectrum has high reliability and is less affected by detector fluctuations. The above results show that the currently prepared diamond detectors can accurately and stably measure the fast neutron flight time information, which can meet the needs of fast neutron beam monitoring.

CSMH adopts the most advanced MPCVD device to prepare a large area of high-quality diamond hot sink with thermal conductivity of 1000-2000W/m.k, with high thickness uniformity and high growth rate; the surface roughness of diamond wafer growth surface Ra < 1 nm by using grinding and polishing special equipment. CSMH has always been adhering to the concept of providing customers with "high quality, low cost, large area of products", constantly based on cutting-edge technology, continuous breakthroughs, leading the diamond thermal injection plate process innovation direction, at present, diamond heat dissipation products and solutions have been applied in 5G base stations, lasers, high-speed rail, new energy vehicles, national defense and military industry and other fields, the future we will continue to carry out product development and innovation, to contribute new strength to scientific and technological progress!

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message