Pos:

Home KnowledgeTechnologyExcellent performance of diamond thermal management, and huge application potentialBefore the 1930s, the gems of choice for engagement rings included opals, rubies, and sapphires. But in the 1940s, De Beers--the South African mining firm that controls the majority of the world's diamond supply--introduced "A Diamond Is Forever." The success of this campaign turned diamond into the symbol of eternal love and dramatically increased demand for the gems.

DIAMOND RING

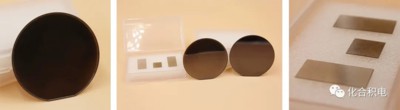

Because of its optical transparency, high thermal conductivity, and resistance to chemical attack, synthetic diamond is an attractive material for making optical windows for instruments used in extremely environments.Today, two start-up companies are staking their futures on the lure of more affordable, laboratory-grown diamond gemstones. But because of diamond's remarkable optical, thermal, chemical, and electronic properties, synthetic diamond promises to offer a lot more than just beautiful jewelry.

In a warehouse in Sarasota, Fla., a company called Gemesis is growing diamonds in two dozen or so high-pressure, high-temperature crystal growth chambers, each the size of a washing machine. Within each chamber, a tiny sliver of natural diamond is bathed in a molten solution of graphite and a proprietary metal-based catalyst at approximately 1,500 °C and 58,000 atm of pressure. Slowly, carbon precipitates onto the diamond seed crystal. A gem-quality, 2.8-carat rough yellow diamond grows in just under three-and-a-half days.

A rough diamond of this size can be cut and polished to give a diamond gem larger than 1.5 carats. (One-half carat is equal to 100 mg of diamond and is roughly the size of a kernel of corn.) Just like naturally occurring yellow diamonds, the yellow lab-grown stones get their color from trace amounts of nitrogen impurities: Replacing fewer than five out of each 100,000 carbon atoms in the diamond crystal lattice with nitrogen atoms gives a yellow diamond.

Naturally occurring fancy-colored diamonds--yellows, blues, pinks, and reds--are very rare and thus very valuable. A Gemesis-created yellow fancy-colored diamond--visibly indistinguishable from a natural one, even to a trained gemologist--can be purchased for about $4,000 per carat. That's about 30% less than the price of a natural diamond of similar color and quality, according to Robert Chodelka, Gemesis' vice president for technology.

SYNTHETIC DIAMONDS are nothing new. Producing them has been a stable business for the past half century. Today, more than 100 tons of the stones is produced annually worldwide by firms like Diamond Innovations (previously part of General Electric), Sumitomo Electric, and De Beers. Tiny synthetic diamonds are used in saw blades for cutting asphalt and marble, in drill bits for oil and gas drilling, and even as an exfoliant in cosmetics.

To grow its gem-quality yellow diamonds (a rough one is shown above), Gemesis uses washing-machine-sized crystal-growing chambers to reproduce the high pressures and high temperatures that nature relies on.The first synthetic diamonds (diamond grit) were produced in the early 1950s by researchers at the Allmanna Svenska Elektriska Aktiebolaget Laboratory in Stockholm, Sweden. They did not immediately publish their work. Soon thereafter, GE researchers reported their own successful diamond synthesis in Nature. Like Gemesis, both teams used conditions that mimic the pressures and temperatures under which diamonds are thought to form naturally.

Prior to Gemesis, GE, Sumitomo Electric, and De Beers had reported the synthesis of large diamonds by similar processes. But these companies marketed their synthetic stones as heat sinks for electronics or used them solely for research purposes. Gemesis, on the other hand, is growing diamonds for jewelry. And because Gemesis' yellow lab-grown diamonds are visually indistinguishable from their mined counterparts, some in the gem industry have expressed concern that the lab-grown diamonds could be passed off as naturals.

Chodelka tells C&EN that Gemesis is "committed to disclosure," noting that all of the firm's diamonds are laser inscribed. In addition, he says trace amounts of nickel left in the diamond from the metal catalyst cause a short-lived phosphorescence after exposure to intense ultraviolet light--a characteristic not shared by most natural diamonds. He also points out that differences in the spatial distribution of nitrogen defects between natural and Gemesis-grown diamonds can be detected by Fourier transform infrared spectroscopy and X-ray absorption spectroscopy.

But Gemesis' business plan only begins with gems. Diamond has an extraordinary range of materials properties: It is the hardest and stiffest material known; is an excellent electrical insulator; has the highest thermal conductivity of any material yet barely expands when

heated; is transparent to UV, visible, and infrared light; and is chemically inert to nearly all acids and bases.

Diamond's superlative properties are fine-tuned by impurities found in the carbon lattice--the same impurities that produce colors in naturally occurring diamond. Diamonds having a perfect carbon crystal lattice without defects or substitutions are colorless. Such diamond has a large band gap--meaning that the energy required to free an electron so it can move through the diamond lattice is high--and therefore is an excellent electrical insulator. But replacing some of the carbon atoms in the diamond lattice with boron--an impurity that produces the pretty blue color in some rare diamonds, including the famed Hope Diamond--transforms diamond into a p-type semiconductor. That's because boron has only three outer-shell electrons and can make only three of four bonds that carbon normally does in the diamond lattice. The result is a missing electron or "hole" that can move freely through the crystal, allowing the diamond to conduct positive charge.

For materials applications that take advantage of these remarkable properties, natural diamonds have obvious flaws: They are prohibitively expensive and limited in size. "Plus, with natural diamonds, you can't control the type or placement of dopants," notes James E. Butler, who is spearheading attempts to study, grow, and use diamond at the U.S. Naval Research Laboratory. As a consequence, Gemesis and many others are eager to create large synthetic diamonds with carefully selected impurities--for instance, boron-doped semiconducting diamonds that could be used to fabricate diamond-based electronic devices that could stand up to heat and chemical attack.

But high-pressure, high-temperature methods of synthesizing diamond like Gemesis' offer limited control of impurities and produce diamonds of limited size, Butler says. Apollo Diamond, a start-up company in Boston, thinks that a low-pressure technique called chemical vapor deposition (CVD) could be the answer. Butler agrees. "As interesting and as important as the high-pressure, high-temperature method is, it won't have the technological impact of diamond growth by chemical vapor deposition," he tells C&EN.

Apollo is using CVD to grow single-crystal diamond wafers big enough to be cut into diamond gemstones of a carat of more. Apollo's method can grow larger diamonds and is less expensive than high-pressure, high-temperature methods, notes Robert C. Linares, Apollo's founder and chairman.

CVD allows finer control of impurities than do high-pressure, high-temperature methods, Linares says. This enables Apollo to produce a wider variety of colored diamonds--including colorless, pink, blue, honey brown, and even black. Like Gemesis, Apollo inscribes its larger lab-grown gems to aid detection. A combination of spectroscopic methods--including infrared spectroscopy and photoluminescence spectroscopy--can normally be used to distinguish Apollo gems from naturally occurring ones, according to Wuyi Wang, a research scientist at the Gemological Institute of America in New York City [Gems & Gemol., 39, 268 (2004)].

A slow, tedious version of the low-pressure CVD process was first documented in 1952 by William G. Eversole of Union Carbide. Back then, "there was a great deal of skepticism that one could grow diamond at low pressures because diamond is thermodynamically unstable with respect to graphite," recalls John C. Angus, professor of chemical engineering at Case Western Reserve University, Cleveland. "Many people said that growth of diamond at low pressure violated the second law of thermodynamics. You were thought to be a fool or a fraud if you proposed this," he says.

Union Carbide subsequently abandoned the project. But a small band of Russian and American scientists, including Angus, pushed forward. By the late 1960s, Angus managed to prove that diamond growth by CVD was indeed feasible. The method was further refined into a viable commercial process in the 1980s by scientists at the National Institute for Research in Inorganic Materials in Tsukuba, Japan.

Hydrogen is the key to growing diamond and not graphite under these conditions, Angus' early work showed. At the surface, the carbon lattice of diamond is decorated with "dangling bonds" that can potentially cross-link to reorganize the surface into more stable graphite. Capping these bonds with hydrogen prevents graphite formation and generates reactive surface sites for attachment of carbon radicals.

Apollo uses chemical vapor deposition to grow plates of very pure diamond (left) that can be cut and polished into beautiful gems (right).In Apollo's CVD reactor, hydrogen gas and methane are flowed through a chamber containing a diamond seed crystal (often a highly polished synthetic one produced by high-pre

ssure, high-temperature methods). The hydrogen gas is split into atomic hydrogen by the action of a hot filament or a microwave-generated plasma. The atomic hydrogen thus generated reacts with methane to give methyl radical and hydrogen gas. The carbon-containing radical species eventually deposit onto the diamond seed, forming new diamond carbon-carbon bonds. But the surface chemistry of how carbon atoms actually attach to the diamond lattice still remains murky, Linares notes.

Apollo's CVD method produces single-crystal diamond, just as nature does. But until relatively recently, most of the diamond grown by CVD methods was polycrystalline, not single-crystal. Polycrystalline diamond is a patchwork of minuscule diamond crystals (and sometimes tiny crystals of graphite). Because it retains many of naturally occurring single-crystal diamond's excellent properties, polycrystalline diamond has been targeted for a number of uses.

For instance, chemistry professor Robert J. Hamers of the University of Wisconsin, Madison, has developed a photochemical method for covalently linking DNA via an organic tether to the surface of polycrystalline boron-doped diamond films made by CVD. Recently, he and graduate student Wensha Yang found that the binding of complementary DNA strands to the DNA-labeled diamond surface can be detected directly by measuring the change in electrical properties of the diamond film. The direct electrical detection allowed by diamond eliminates the need for labor- and time-intensive labeling steps required by other biosensing methods.

And because semiconducting diamond can generate a wider range of potentials than other electrode materials, electrodes made of this material can be used to study redox reactions that can't be studied with conventional electrodes, notes assistant professor of chemical engineering Heidi B. Martin of Case Western. That and the many other excellent properties of diamond have led chemistry professor Greg M. Swain of Michigan State University and many other scientists to use CVD to grow polycrystalline boron-doped diamond electrodes that can detect--and in some cases degrade--redox-reactive organic contaminants in water supplies. In addition, Martin is using CVD to grow highly conductive boron-doped polycrystalline diamond microelectrodes that could directly sense a variety of redox-active neurotransmitters during neurotransmission. The diamond microelectrodes should be more sensitive, stable, and versatile than ones made of other materials, Martin says.

U.K.-based Element Six, formerly known as De Beers Industrial Diamonds, is already selling CVD-grown polycrystalline diamond films for various applications, notes Steven E. Coe, the firm's R&D manager. The company markets its polycrystalline diamond for use as heat spreaders in high-power electronic devices. It also uses the material to fashion surgical blades that are resistant to dulling and optical windows for high-powered CO2 lasers.

To make diamond by chemical vapor deposition, hydrogen gas and methane are flowed through a chamber containing a substrate. Heat or a microwave-generated plasma is used to split hydrogen gas into atomic hydrogen, which then reacts with methane to give methyl radical and hydrogen gas. The carbon-containing radical species eventually deposit as diamond onto the substrate.

NEVERTHELESS, using single-crystal diamond instead of polycrystalline diamond in such applications has advantages. Because the C—C bonds that hold its patchwork of tiny crystals together are weaker than C—C bonds in single-crystal diamond, polycrystalline diamond isn't quite as thermally conductive, as optically transparent, or as strong as single-crystal diamond. In fact, for some applications--particularly those such as electronics that require the highest carrier mobility--only single-crystal diamond will do, Linares tells C&EN. For diamond to live up to its promise as an alternative to silicon for fabricating electronic devices, "what's required is high-quality, single-crystal CVD diamond in usable sizes," Coe adds.

Coe and his colleagues at Element Six proved this was possible just over a year ago [Science, 297, 1670 (2002)] and now can grow high-quality, single-crystal diamond wafers that are 5 mm square. Linares tells C&EN that Apollo currently can grow high-quality, single-crystal diamond wafers that are about double that size. He predicts that within the next four years the company will be cranking out 4-inch square wafers.

Both Coe and Linares suggest that, thanks to its high thermal conductivity and electrical carrier mobility, single-crystal semiconducting diamond will be the ultimate material for fashioning high-powered electronic devices. Element Six is already making some simple prototype devices, such as switches, from p-type semiconducting diamonds, Coe says. But mo

st devices will require both hole-conducting (p-type) and electron-conducting (n-type) diamond semiconductors. The former is easy: Both Element Six and Apollo report that they can use their CVD methods to make boron-doped single-crystal diamond wafers that are excellent p-type semiconductors. Producing n-type semiconducting diamond has proven more challenging, however.

A number of potential n-type dopants have been investigated, most notably phosphorus. A group led by Hisao Kanda of Japan's National Institute for Materials Science has shown that doping diamond with phosphorus gives n-type semiconducting diamond. The team has gone on to show that phosphorus-doped and boron-doped diamond can be combined to make a simple electrical device called a p-n junction.

But so far neither phosphorus nor any other n-type dopant has demonstrated exactly the right electrical properties, according to Butler. Butler, Jacques Chevallier of the Laboratoire de Physique des Solides et de Cristallogénèse, in Meudon, France, and their colleagues recently reported that impregnating boron-doped CVD diamond with deuterium yields n-type semiconducting diamond [Nat. Mater., 2, 482 (2003)]. Despite this promising development, Angus--whose own lab is doping CVD diamond with a combination of boron and sulfur to get n-type semiconductivity--comments that "all of the n-type work, including ours, is interesting in a scientific sense but not yet practical for devices."

The payoff for such work is potentially huge: Today's microchips are running hotter and hotter because more and more transistors are being crammed onto them. If the trend continues, silicon may not be able to take the heat. Diamond could be the perfect solution.

Despite its superior combination of electrical, optical, thermal, and chemical properties, though, diamond may never totally replace silicon for two reasons: Silicon is both cheap and firmly entrenched in the computer industry. Still, Reza Abbaschian, a professor of materials science and engineering at the University of Florida, Gainesville, whose lab helped to perfect Gemesis' diamond-growing method, believes that "for certain specialized applications, such as devices that run at high power or high temperature, diamond may be just the ticket."

We is committed to the development and production of diamonds. It has mature products such as diamond heat sink, wafer-level diamonds, diamond coatings and other rich products, providing professional thermal management solutions for various fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message