Pos:

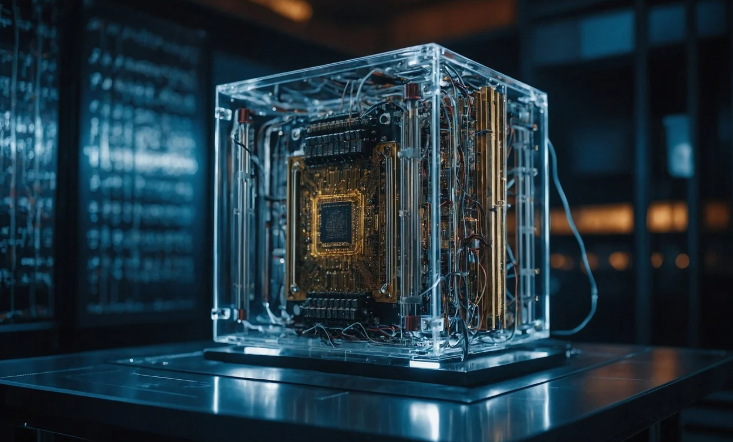

Home KnowledgeTechnologyDiamond Heat Sink : The Ideal Thermal Interface and Substrate Material for Next-Generation ChipsIn today’s era of rapidly advancing semiconductor technology, every leap in CPU performance is accompanied by a dramatic surge in heat generation. As manufacturing processes edge closer to physical limits, the number of transistors per unit area grows exponentially, and the resulting "thermal barrier" is emerging as a bottleneck restricting the improvement of computing performance. Diamond is quietly reshaping the technical landscape of CPU heat dissipation and has now become a new hope for solving chip thermal challenges.

Diamond’s outstanding performance in thermal management stems from its unparalleled physical properties. In nature, diamond boasts a thermal conductivity of up to 2200 W/(m·K) — five times that of copper, four times that of silver, and over ten times that of aluminum. Behind this remarkable figure lies diamond’s perfect crystal structure: each carbon atom is bonded to four adjacent atoms via strong covalent bonds, forming an extremely stable tetrahedral structure. This allows lattice vibrations (phonons) to propagate almost unimpeded, enabling ultra-high thermal conduction efficiency.

Beyond its exceptional thermal conductivity, diamond also features a low coefficient of thermal expansion (0.8×10⁻⁶/K), high dielectric strength (10⁷ V/cm), and excellent chemical stability. In CPU thermal management scenarios, these properties translate into multiple advantages: efficient heat transfer capability, thermal expansion performance matching silicon chips, and the ability to directly contact chips as an electrical insulator. These combined characteristics make diamond the ideal thermal interface material (TIM) and heat sink substrate material.

In CPU cooling systems, diamond heat sink plates are mainly applied in three key areas: as a thermal interface material between the chip and heat sink, as an integrated heat spreader (IHS) for chip packaging, and as a localized heat sink for high-power regions.

As a thermal interface material, diamond plates replace traditional thermal greases or phase-change materials, reducing interface thermal resistance by more than 60%. Intel’s laboratory tests show that CPUs using diamond thermal interface materials can achieve a 10–15°C lower core temperature under high loads compared to those using conventional materials, which directly translates to higher and more stable boost frequencies.

At the chip packaging level, diamond heat spreaders have been adopted in the high-performance computing sector. Some models of IBM’s POWER series processors utilize diamond composite heat spreaders, enabling a 20% increase in thermal design power (TDP) while keeping chip temperatures within safe limits. A more innovative approach is to use diamond as the chip substrate: through nanobonding technology, the chip’s transistor layer is directly transferred onto a diamond substrate, achieving the shortest possible heat dissipation path. DARPA research indicates that this structure can reduce local hotspot temperatures by over 40%.

With heterogeneous integration and chip stacking (3D IC) becoming mainstream trends, diamond heat sink plates play an especially prominent role in interlayer thermal management. AMD has explored diamond interposers in its 3D V-Cache technology, effectively resolving the "thermal coupling" issue of stacked chips and increasing L3 cache capacity threefold without compromising thermal performance.

Practical application data demonstrates that diamond heat sink plates deliver significant improvements to CPU performance. In the server CPU segment, chips adopting diamond cooling solutions can boost sustained all-core frequencies by 15–25% or reduce cooling system energy consumption by 20–30%. For overclocking enthusiasts, diamond cooling modules lower extreme overclocking temperatures by 10–20°C, setting multiple world records.

In terms of energy efficiency, diamond thermal management technology reduces CPU power consumption by 8–12% at equivalent performance levels, which has far-reaching implications for the operational costs of data centers and supercomputers. Take a 10-megawatt data center as an example: after adopting a diamond cooling solution, it can save over $500,000 in annual electricity costs and reduce carbon emissions by approximately 3,000 tons.

Diamond heat sink plates not only represent the current pinnacle of CPU thermal management but also signal the development direction of next-generation chip cooling technologies. As 5G, artificial intelligence, and high-performance computing impose ever-stricter demands on chip heat dissipation, diamond — the "king of thermal management" — is poised to usher in a new era of cooling technology.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), which has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message