Pos:

Home KnowledgeTechnologyBeyond Cooling: Diamond Heat Sinks Are Reshaping the Future of High-End Medical DevicesIn the field of medical devices, efficient heat dissipation is not only critical to device performance, but also directly linked to patient safety and the efficacy of diagnosis and treatment. With the continuous advancement of medical technology, the power density of devices is constantly increasing, making heat dissipation a bottleneck restricting the development of many high-end medical devices.

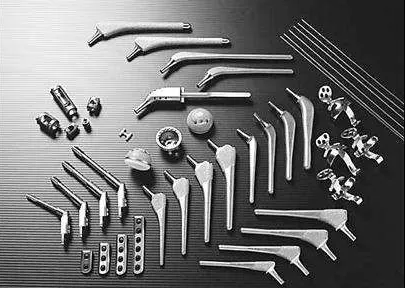

The application of diamond heat sinks is particularly prominent in high-power laser medical equipment. Modern laser surgical devices, ophthalmic treatment instruments and dermatological therapy equipment generally adopt high-power semiconductor lasers. These lasers generate a large amount of heat during operation; if the heat cannot be dissipated in a timely manner, it will lead to wavelength drift, reduced output power, or even permanent damage. Traditional heat dissipation materials such as copper and aluminum can no longer meet the growing heat dissipation demands. Thanks to their exceptional thermal conductivity, diamond heat sinks can quickly transfer the heat generated by lasers, ensuring that devices operate stably at optimal performance levels. For instance, laser surgical equipment needs to work continuously for tens of minutes, and any temperature fluctuation may affect cutting precision. Laser systems integrated with diamond heat sinks can control temperature variations within 0.5°C, significantly enhancing surgical safety.

Diamond heat sinks also play an irreplaceable role in medical imaging equipment. Components with high heat flux density are ubiquitous in this field, including X-ray tubes in CT scanners, gradient coils and radio-frequency amplifiers in MRI machines, and photomultiplier tubes in positron emission tomography (PET) systems. Take CT scanners as an example: their X-ray tubes can rapidly heat up to several hundred degrees Celsius while generating high-energy radiation. Traditional heat dissipation methods are not only inefficient, but may also cause structural damage to equipment due to mismatched thermal expansion coefficients. The thermal expansion coefficient of diamond heat sinks is close to that of semiconductor materials, allowing them to integrate seamlessly with semiconductor components in medical devices and avoid thermal stress issues caused by temperature changes. Studies have shown that CT equipment equipped with diamond heat sinks can extend the service life of X-ray tubes by over 30% while significantly improving image quality.

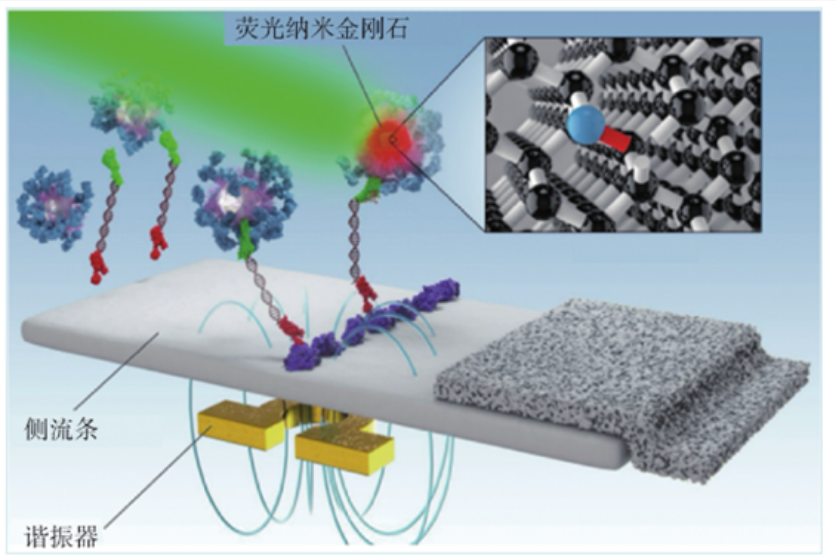

In the field of cutting-edge medical research, diamond heat sinks are driving breakthroughs in quantum medicine and brain-computer interface (BCI) technologies. Quantum dot fluorescence labeling is a key technology for early cancer diagnosis, but quantum dots are prone to "fluorescence quenching" as temperatures rise, resulting in signal attenuation. Diamond heat sinks can effectively maintain the stable operating temperature of quantum dots, increasing detection sensitivity by an order of magnitude. In the BCI field, high-density neural electrode arrays are essential for recording and decoding brain activities, but the heat generated by these microelectrodes during operation may damage fragile brain tissues. The miniaturized application of diamond heat sinks has enabled the development of "zero thermal damage" neural interfaces, opening up new avenues for the treatment of neurological disorders such as Parkinson’s disease and epilepsy.

Gene sequencers represent another typical application scenario for diamond heat sinks. Third-generation gene sequencing technology relies on fluorescence labeling and high-speed imaging, and detection chips generate substantial heat during operation. Temperature fluctuations directly impact sequencing accuracy, a requirement that traditional heat dissipation solutions struggle to meet. Gene sequencers equipped with diamond heat sinks can achieve temperature stability within ±0.1°C, raising the accuracy of single sequencing runs from 90% to over 99.9% and laying a solid technical foundation for precision medicine.

As medical devices become increasingly sophisticated and intelligent, heat dissipation is no longer a simple engineering issue, but a core technology that impacts device performance, patient safety, and even the revolution of diagnosis and treatment. With their outstanding performance, diamond heat sinks are providing reliable thermal management support for high-end medical devices such as high-power laser surgical equipment, medical imaging systems, and gene sequencers. As technology advances and costs decrease, this high-end technology once limited to the aerospace industry is gradually expanding into broader medical applications, offering critical support for precision medicine, minimally invasive surgery, and early disease diagnosis.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), which has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message