Pos:

Home KnowledgeTechnologyDiamond Heat Sinks: A High-Performance Material Innovation in the Medical Laser FieldAs we all know, the core of a laser requires an extremely high energy density, and during this process, a large amount of heat is generated by the equipment. Thanks to the unique physical properties of diamond, it boasts significant advantages in medical laser applications. Moreover, stability and safety are also crucial factors in medical laser systems. Therefore, diamond is bound to have its distinct highlights in the future of medical laser applications.

Medical laser devices impose extremely stringent requirements on the optical transmission efficiency, thermal stability, biocompatibility, and mechanical strength of core materials, and diamond precisely offers comprehensive performance advantages:

Ultra-High Optical Transparency: Diamond achieves an optical transmittance of 80%–95% across a broad spectral range from ultraviolet to infrared. Particularly for the near-infrared bands (e.g., 1064nm, 1319nm) and ultraviolet bands (e.g., 266nm) commonly used in medical lasers, it exhibits almost zero absorption loss. This minimizes laser energy attenuation and ensures treatment precision.

Extreme Thermal Conductivity: With a thermal conductivity of 2000–2500 W/(m·K), diamond is 5 times that of copper and over 10 times that of sapphire. It can rapidly dissipate localized high temperatures generated during laser operation, preventing thermal deformation or burnout of the material itself. Meanwhile, it reduces heat diffusion to surrounding biological tissues, lowering the risk of postoperative damage.

Excellent Biocompatibility: Chemically stable, diamond does not react with human tissues or bodily fluids and is non-cytotoxic. Its surface can be easily modified to achieve bioinertness or specific adsorption, avoiding immune rejection or inflammatory responses in implantable applications.

Ultra-High Mechanical Strength: Boasting a Mohs hardness of 10, diamond features exceptional compressive strength and wear resistance. It can withstand harsh operating conditions of medical laser equipment, such as high-frequency vibrations and high-pressure sterilization (e.g., autoclave sterilization), significantly extending the service life of components.

Corrosion and Radiation Resistance: Diamond has strong resistance to acids, alkalis, organic solvents, and other corrosive substances. It also tolerates long-term laser irradiation without performance degradation, making it suitable for the stable long-term operation of high-power medical laser systems.

(I) Core Components of Laser Surgical Instruments

Light-Guiding Components for Laser Scalpels: Traditional optical fibers used in laser scalpels are prone to high-temperature aging, wear, and fracture. In contrast, light-guiding rods and windows made of diamond enable efficient laser energy transmission and rapid heat dissipation through their high optical transmittance and thermal conductivity. They are especially suitable for high-power laser procedures such as tumor ablation and minimally invasive hepato-biliary surgery, reducing intraoperative energy loss and the risk of instrument failure.

Laser Focusing Lenses and Mirrors: In ophthalmic procedures including phacoemulsification for cataracts and refractive surgeries (e.g., femtosecond laser myopia correction), diamond focusing lenses can precisely focus laser beams into micron-scale spots while rapidly dissipating heat at the focal points, preventing thermal damage to corneal or lens tissues. Diamond mirrors ensure the stability of laser optical paths and enhance surgical precision by virtue of their high reflectivity and wear resistance.

(II) Laser Treatment Devices for Dermatology and Dentistry

Dermatological Laser Treatments: In applications such as laser spot removal, hair removal, and scar revision, high-power lasers tend to cause overheating on the surface of treatment heads, compromising therapeutic outcomes. Diamond optical windows enable efficient heat dissipation while maintaining uniform laser beam output. They are particularly applicable to high-end devices like picosecond lasers and fractional lasers, improving the safety and comfort of treatments.

Dental Laser Cutting Probes: Dental lasers are widely used for tooth preparation, caries treatment, and periodontal disease repair. Laser probes coated with diamond maintain stable shapes when in contact with hard dental tissues, thanks to their high hardness and wear resistance. Meanwhile, their superior thermal conductivity rapidly dissipates heat generated during cutting, avoiding damage to dentin and dental pulp nerves.

(III) Implantable Laser Treatment Devices

In fields such as interstitial tumor irradiation and chronic pain laser therapy, implantable laser devices need to operate inside the human body for extended periods. Miniature laser emitters encapsulated in diamond can protect internal core components via their biocompatible outer shell, while enabling precise conduction of laser energy. This prevents corrosion by bodily fluids or tissue reactions, making them suitable for minimally invasive treatment of deep-seated tumors such as prostate cancer and pancreatic cancer.

(IV) Heat Dissipation and Protection Components for Laser Medical Equipment

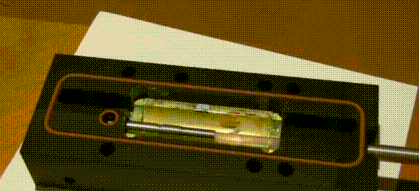

Core components of high-power medical laser systems, such as laser generators and resonant cavities, generate substantial heat during operation. Diamond heat sinks and heat dissipation substrates can rapidly conduct heat away through their extreme thermal conductivity, maintaining stable operating temperatures of equipment and preventing fluctuations in laser output power. In addition, protective windows made of diamond films can block contaminants in medical environments (e.g., dust, bodily fluids) from eroding core laser components without interfering with laser transmission.

In the future, the application of diamond in the medical laser field will move toward greater precision, miniaturization, and intelligence:

In ophthalmology, diamond microlenses will support ultrashort-pulse lasers to achieve cell-level precision treatment.

In oncology, diamond-encapsulated targeted laser devices will enable precise targeted ablation of tumors.

In minimally invasive surgery, integrated instruments combining diamond’s light-guiding, heat-dissipating, and sensing functions will further enhance surgical precision and safety.

With its unique optical, thermal, mechanical, and biocompatibility advantages, diamond has become the core material support for the upgrading of medical laser technology.

As synthetic technologies and processing techniques continue to advance, the application scenarios of diamond in medical lasers will expand further. It will not only drive performance innovations in medical laser equipment but also provide safer, more efficient, and more precise solutions for clinical treatments, injecting new momentum into the development of global healthcare.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite substrates,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), which has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message