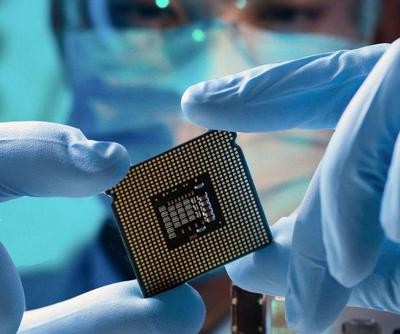

With the advancement of third-generation semiconductor application technologies represented by wide-bandgap compounds such as silicon carbide, gallium nitride, diamond, and aluminum nitride, 5G, millimeter wave communications, new energy vehicles, photovoltaic power generation, aerospace and other strategies are emerging The performance of the industry's key core devices will be qualitatively improved.

When the first- and second-generation semiconductor materials are gradually approaching their physical limits, the third-generation semiconductor materials, which are expected to break through the bottleneck of traditional semiconductor technology, become the darling of industry development.

In fact, the reason why domestic semiconductor materials are divided into "generations" is somewhat due to the three industrial revolutions that have come with the large-scale application of semiconductor materials.

The first generation of semiconductor materials is represented by silicon (Si), which replaced bulky electron tubes and promoted the rapid development of the microelectronics industry centered on integrated circuits.

The second-generation semiconductor materials are mainly gallium arsenide (GaAs), indium antimonide (InSb), etc. Indium phosphide semiconductor lasers are key components of optical communication systems, and high-speed gallium arsenide devices have opened up new industries for optical fiber and mobile communications. .

The third-generation semiconductor materials represented by silicon carbide (SiC) and gallium nitride (GaN) have effectively promoted the development of semiconductor lighting, display, electric vehicles and other industries.

From the perspective of the three important parameters of semiconductor materials, the third-generation semiconductor materials have electron mobility (high-frequency working performance under low-voltage conditions), saturation drift rate (high-frequency working performance under high-voltage conditions), and band gap (the device’s Withstand voltage performance, maximum operating temperature and optical performance) are better than silicon devices in three indicators.

Among them, the most noticeable is the "Wide Band-Gap (WBG)" of the third-generation semiconductor. The advantage of the high band gap is that the device is resistant to high voltage and high temperature, and has high power, anti-radiation, strong electrical conductivity, fast working speed and low working loss.

But the superiority of the parameters does not mean that one generation of semiconductor materials is better than one generation. In fact, the first, second, and third-generation semiconductor materials each have their own suitable application areas. For a long time in the future, these three-generation semiconductor materials will coexist.

Although silicon materials do not have such great parameters, there is currently no semiconductor material that can compete with it in terms of reliability and overall performance. As the "ultimate semiconductor", diamond is expected to be widely used in many application fields.

The 2021 top ten technology trends released by Alibaba Dharma Academy put "the third generation of semiconductors ushering in an explosion of applications" at the top.

Dharma Institute believes that in the next five years, the third-generation semiconductor materials will achieve breakthroughs in materials growth, device preparation and other technologies. Electronic devices based on third-generation semiconductor materials will be widely used in 5G base stations, new energy vehicles, UHV, Scenarios such as data centers greatly reduce overall energy consumption.

It is foreseeable that with the expansion of demand for third-generation semiconductors in markets such as 5G and new energy vehicles, and continuous breakthroughs in preparation technology, especially large-scale material growth technology, the cost-effectiveness of third-generation semiconductors will also be improved.

We focuses on the R&D and production of third-generation semiconductor materials and devices. At present, there are diamond heat sinks, wafer-level diamond substrates, metallized diamonds, silicon-based aluminum nitride and other products, which are available in batches. Details are welcome. Contact.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message