Diamond is a metastable allotrope of carbon. For electronics applications, the industry mainly uses synthetic diamonds, which are grown via a chemical vapor deposition (CVD) process.

There is interest in perhaps the ultimate power device–diamond. Diamond has a wide bandgap (5.45 eV), a high breakdown field (10MV/cm), and high thermal conductivity (22W/cmK). Silicon has a bandgap of 1.1 eV. Wide bandgap refers to higher voltage electronic band gaps in devices, which are larger than 1 electronvolt (eV).Diamond-related products include diamond heat sinks/wafer-level diamonds, etc.

It could take years before diamond FETs reach the mainstream. Over the years, a number of entities have produced diamond FETs, at least in the lab. For example, Waseda University in Japan, one of the leaders in the area, recently presented a paper on a diamond FET for 1,000-volt applications.

Instead of a traditional boron-doped p-type diamond FET, Waseda makes use of p-channel FETs, based on an H-terminated (C-H) diamond surface. In simple terms, when the hydrogen-terminated diamond is exposed to air, the C-H diamond FET becomes highly conductive at the surface.

To make diamond FETS, Waseda grows an undoped diamond layer on a diamond substrate using microwave plasma assisted CVD with a thickness of 0.5¼m. A key to the device is the formation of the dense surface holes (2D hole gas, 2DHG) on the top of the FET. Researchers use an atomic layer deposition (ALD) process to apply Al2O3 at 450°C to reproduce 2DHG without adsorbates.

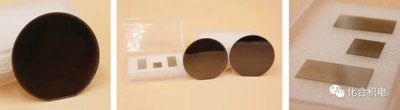

Diamond fins are popular because of their excellent thermal conductivity. UNICS specializes in providing diamond heat sink and other products, and provides professional diamond heat dissipation solutions for you.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message