Pos:

Home KnowledgeTechnologyBreakthroughs in Advanced Packaging Diamond Heat Dissipation TechnologiesDiamond is the highest thermal conductivity and low coefficient of thermal expansion among the known materials, and has good electrical insulation, which is very suitable for the application of electronic packaging materials. How to apply these advantages of diamond to the heat dissipation of electronic devices has become a hot research topic.

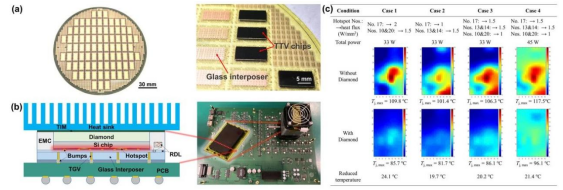

A Chinese research team has made another breakthrough in the field of integrated chip-diamond heat dissipation technology for advanced packaging glass interposer. The results show the team has overcome industry challenges such as microbump protection and wafer warping to successfully integrate a polycrystalline diamond substrate into the backside of a 2.5D glass interposer package chip, and used a thermal test chip (TTV) to study its heat dissipation characteristics. Using the ultra-high thermal conductivity of diamond, the integrated diamond thermal substrate reduces the maximum junction temperature of the chip by as much as 24.1 ℃ and the thermal resistance of the chip package by 28.5% when the hot spot power density of the chip is ~2 W/mm2. The advanced packaging chip-diamond has extremely superior thermal performance, and the advanced packaging integrated chip heat dissipation based on diamond substrate has significant application prospects.

Characterisation of polycrystalline diamond substrate integrated into the backside of glass adapter plate encapsulated chips and heat dissipation performance.

This research combines diamond low-temperature bonding with glass adapter plate technology, and for the first time realises the integration of polycrystalline diamond substrate into the backside of glass adapter plate encapsulated chip. This technical route is consistent with the development trend of miniaturisation of electronic equipment size and light weight, and at the same time, it is effectively compatible with the existing heat dissipation scheme, which has become an important breakthrough path to achieve efficient heat dissipation of the chip, and has promoted the industrialisation of diamond heat dissipation substrate in the integration of advanced encapsulated chips.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds, and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows, diamond hetero junction integrated composite substrates, etc. Among them, the thermal conductivity of diamond heat sinks is 1000-2200W/(m.k), and the surface roughness of diamond wafer Ra<1nm. lt has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message