Pos:

Home KnowledgeTechnologyDiamond substrate: the best material to solve high heat dissipation problemsWith the development of application requirements becoming increasingly clear, the performance requirements for high-power devices are becoming higher in the future. Although GaN based electronic devices can provide ultra-high current and power density performance, many failures in high-end electronic systems can be directly attributed to a lack of appropriate thermal management.

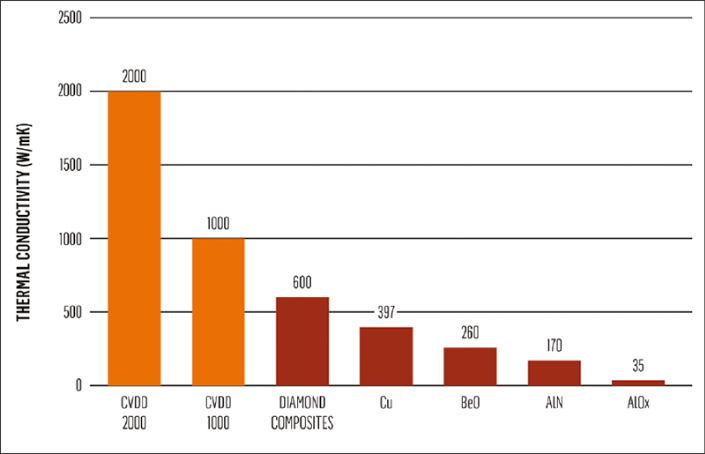

In traditional solutions, the integration of SiC (400 W/mK) substrate and GaN provides the best choice for GaN HEMT and MMIC technologies for high-power applications. However, despite the use of SiC substrates, sufficient heat dissipation remains the limiting factor determining maximum power dissipation in GaN based electronic devices. Therefore, long-term reliability is often achieved by reducing the maximum power dissipation index. Using CVD diamond (2000 W/mK) as a heat sink is a much better heat dissipation solution, and its power density may increase by three times or more compared to current top GaN devices.

Comparison between CVD diamond and "traditional" heat dissipation materials

Diamond has a series of remarkable characteristics, making it the most effective material for solving thermal management problems. CVD (Chemical Vapor Deposition) achieves control over grain size, grain purity, and grain interfaces, enabling the generation of high-quality and highly repetitive polycrystalline diamonds to meet the thermal conductivity requirements of special applications.

CVD diamond provides a more efficient, compact, and simplified solution for 5G and other high-power electronic systems. Using diamond grown using CVD technology as a high-performance heat sink can ensure the effective performance of many disruptive electronic components, from GaN solid-state RF X-band power amplifiers (PA) to advanced ASICs, to laser diodes, among others. After using CVD diamond heat sinks, the device can operate at higher power levels without increasing the operating junction temperature, thereby extending its service life and improving reliability.

CSMH is committed to the research of diamond and other heat sink materials, mastering internationally leading diamond thermal management products and solutions. It currently has core products such as wafer grade diamond, diamond heat sinks, diamond windows, and diamond heterojunction integrated composite substrates. Among them, the surface roughness of diamond wafer Ra<1nm; The thermal conductivity of diamond heat sinks is as high as 1000-2200W/m.k, and the technical indicators have reached the world's leading level. Diamond heat sink has been applied in many fields such as high-power electronic devices, 5G base stations, new energy vehicles, aerospace, etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message