Aging testing is one of the important means to improve product reliability. Through aging testing, problems and defects of products under various environmental conditions can be exposed, and these problems can be repaired and improved, thereby improving product reliability and service life. In aging testing, temperature plays a crucial role. If heat dissipation technology is not done well, it will directly affect device performance, lead to a decrease in lifespan and reliability, and even damage the chip. The ultra-high thermal conductivity of diamond will play an important role in aging test equipment.

Diamond has excellent properties such as wide bandgap, high thermal conductivity, high breakdown field strength, high carrier mobility, high temperature resistance, acid and alkali resistance, corrosion resistance, and radiation resistance. It is currently one of the most promising semiconductor materials, and its classic application scenario is in the field of thermal management. By utilizing the high thermal conductivity of diamond, the temperature thermal equilibrium time during the testing process can be shortened, and the efficiency of aging testing can be improved.

Welding the diamond layer onto the copper base can greatly improve the heat dissipation capacity and wear resistance of the copper base. The chip can be directly placed on the surface of the diamond layer on the copper base to meet the requirements of high-power chip aging testing, avoiding the use of soft solder melting or anti sticking causing chip scrap.

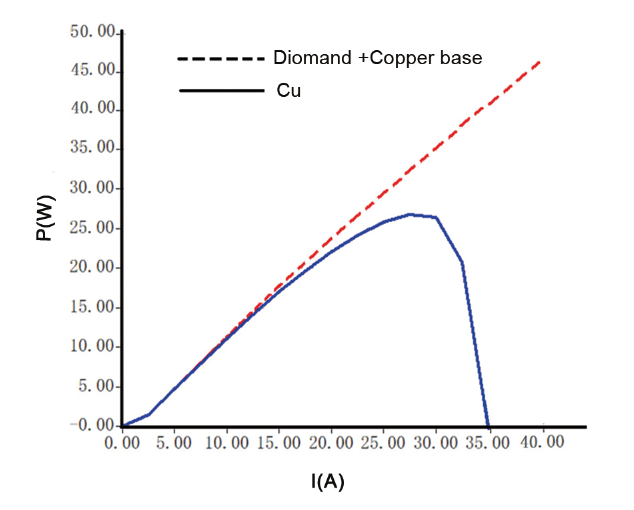

The chip aging test data shows that (the chip is in contact with the test surface using a crimping method), using a diamond+copper socket scheme, the chip test current is at 40A, and the chip power is still on the rise. However, when only copper is used, the current is at 30A, and due to heat dissipation issues, the power reverses, failing to meet the test requirements.

CSMH focuses on the production and research of diamond materials, mastering internationally leading diamond production processes, and possessing mature product systems and thermal management solutions. Among them, the surface roughness of diamond wafers is Ra<1nm, and the thermal conductivity of diamond heat sinks reaches 1000-2200W/(M.K). We can provide customized services, including diamond wafers, diamond heat sinks, diamond windows, and diamond heterojunction integrated composite substrates.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message