Pos:

Home KnowledgeTechnologyDiamond wafer are used for heat dissipation in high-density electronic devices, and diamond microchaAt present, the miniaturization and integration of electronic devices bring new challenges to thermal management. Hot spots have become a key thermal feature of today's high-power density electronics, such as central processing units, laser dioxides, and insulated gate bipolar transistors, where hot spots can have a heat flux of 1000 W/cm² or more. At such a high heat flux, insufficient heat dissipation can lead to an excessively high temperature increase, which can reduce equipment performance and accelerate equipment failure. Therefore, for high-density electronic devices, heat dissipation is the main research direction.

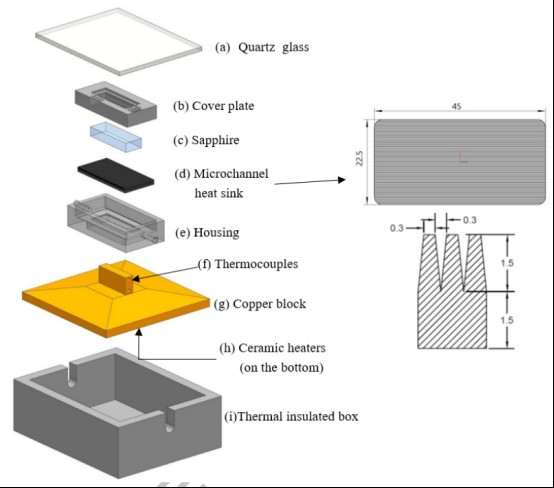

Figure 1 Test structure diagram

Figure 1 shows the structure of the test section, where a microchannel heat sink is placed. The evaporator designed for this study consists of a diamond microchannel radiator (d), a Mo-Nb alloy shell (b, e) and a transparent sapphire window (c), welded together by vacuum brazing technology, strictly sealed high-pressure ammonia, and detected leakage rates of less than 3.0×10-10 Pa·m3/s by helium mass spectrometry. The heat load is provided by the copper block. If the ceramic heater directly provides more than 25 W/cm2 of heat flow, excessive heat source temperature may damage the heater.With this in mind, we designed the copper block (g) as the heat transfer medium from the heater to the radiator, which has a large bottom area (80×80 mm2) but a small upper surface area (25×6 mm2), i.e. a direct heating area. Four 40×20mm2 ceramic heaters (h) are bonded to a fixed position at the bottom of the copper block using silicone rubber (GD414) and Ga-In alloy liquid metal (K-ZOON TG-2 type) as the interface filler to reduce the thermal contact resistance. The heater is powered by a DC power supply (Agilent 6675A DC, Agilent Technologies Inc.) with an adjustable voltage of 0-120V and a current of 0-18A. As the heat flow directional heat area decreases, the heat conducted by the ceramic heater to the radiator becomes more and more intense along the direction of the heat flow, and eventually accumulates on the upper surface.The upper surface of the copper block is attached directly to the base surface of the heat sink (45×22.5 mm2), which is a good simulation of the actual heat dissipation scenario under non-uniform high heat flow density. The interface is also filled with gallium-indium alloy liquid metal. Through the special design of the copper block, this study can obtain a high-density heat flow of up to 267 W/cm2 in the direct heating area without damaging the ceramic heater. The evaporator, copper block and ceramic heater are assembled together and placed in an insulated box (i) to prevent heat loss into the environment. The thermal conductivity of high foamed polyethylene wrapped outside the box is less than 0.034 W/m×K. Quartz glass (a) is draped over the top of the test area to provide a window for visualization. The high-speed camera is then placed in front of the window to record the flow boiling pattern during evaporation.

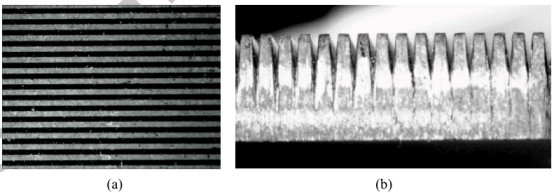

Figure 2 Shape of the microchannel (a) Top view (left) (b) Section view (right)

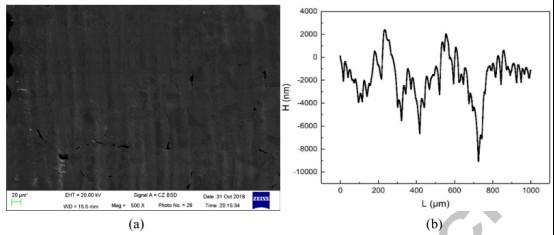

Surface roughness is an important parameter for characterizing flow boiling, especially microchannels. Before the experiment, the inner wall of the microchannel was observed under 500 × ZEISS EVO18 scanning electron microscopy, and the observed images are shown in Figure 2(a). The DEKTAK150 surface profiler measured a surface roughness ra of 2027 nm for the inner wall of the microchannel, and the distribution results are shown in Figure 2(b).

Fig. 3 Surface roughness of the inner wall of the microchannel (a) Microscopic topography of the surface (b) Qualitative measurement of surface roughness.

In contrast, it can be seen that after the use of diamond, the surface roughness of the microchannel is reduced, the surface flow boiling of the surface is reduced, and the temperature is reduced.

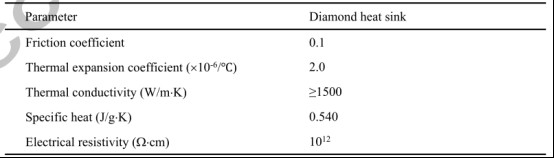

Table 1 Physical properties of radiators made of diamond

The thermal conductivity of the diamond radiator is not less than 1500W/m.k, while the thermal conductivity of synthetic diamond can be as high as 2000W/m.k. It can be seen that diamond is simply a heat dissipation material tailored for microchannels.

CSMH focuses on the research and development and production of the third generation of semiconductor material diamond, and vigorously promotes the commercial application of diamond-related products, there are diamond hot sink sheet, wafer-level diamond, diamond coating (GaN) and other products, diamond wafer Ra<1nm, diamond hot sink sheet thermal conductivity 1000-2000W/m.k, the use of diamond heat sinking (heat sink) of high-power semiconductor lasers have been widely used in optical communications, laser diodes, power transistors, electronic packaging materials, etc., and have been highly recognized by the industry.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message