Usually you see ultra-high-power devices still working in an orderly manner, what is the first thing you think of? Is it the high-precision connection between parts, or the clear division of labor between the primary and secondary systems, or the difficulty of the task? According to statistics, power device failures caused by thermal concentration account for 55% of the total failure rate, and the thermal design of products has a crucial impact on the reliability of products. Semiconductor devices are small in size and have a long life, in addition to the field of communication, they can also be applied in radar, sound measurement, and medical treatment, but studies have found that heat dissipation affects the life and use of semiconductor devices. In addition, the CPU temperature is too high will cause the computer to automatically shut down, blue screen, crash, computer stuttering, etc., long-term temperature is too high, affecting its service life. Whether it's high-power devices or power electronics, thermal management is especially important.

Diamond's band gap width, high thermal conductivity, high breakdown field strength, high carrier mobility, high temperature resistance, acid and alkali resistance, corrosion resistance, radiation resistance, superior performance makes it play an important role in high power, high frequency, high temperature field, etc., and its classic application scenarios include diamond thermal management materials.

The advantages of diamond are as follows:

Extremely high thermal conductivity: thermal conductivity 2200W/m.K, diamond has the highest thermal conductivity at room temperature.

Extremely high dielectric breakdown characteristics: the breakdown electric field is 107V/cm, which is 50 times that of GaAs, 2 times that of GaN, and 2.5 times that of SiC.

Extremely high power capacity: the allowable power consumption capacity is more than 2500 times that of Si material; It is especially suitable for the production of high-power electronic devices.

Low dielectric constant: The dielectric constant is 5.7, which is about 1/2 of GaAs, which is less than half of InP.

High Saturated Carrier Speed: Saturated carrier velocities are 12.7 times faster than GaAs, Si, or InP, and maintain high rates as the electric field strength increases.

High carrier mobility: The electron mobility is 4500c㎡/(V·s), which is higher than most materials, suitable for making high-frequency electronic devices.

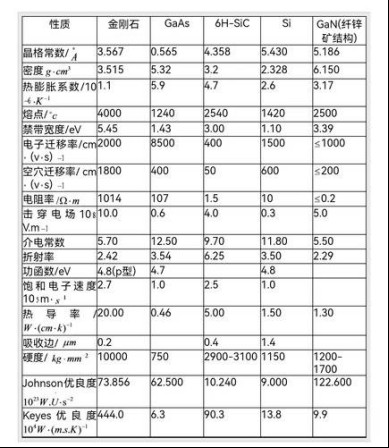

Figure 1 Characteristics of diamond and other heat dissipation materials

Diamond sinking effectively solves heat dissipation problems and improves the performance of high-power devices in the same size. Currently, CVD diamond thermal blankets can be widely integrated into thermal solutions in three ways:

1. Independent individual diamond units are joined by metallization and welding, e.g. with Ti/Pt/Au sputtered deposited metal and AuSn eutectic welding);

2. Prefabricated wafers support multiple devices, enabling device manufacturers to process wafers in large batches (e.g. metallization and placement). After such additional steps are completed, these chips can serve as substrates for individual subassemblies.

3. Direct use of diamond coating.

CSMH is a high-tech enterprise focusing on the research and development and production of third-generation (wide bandgap band) semiconductor substrate materials and devices, and is committed to becoming the world's leading wide bandgap semiconductor materials and devices company. We have always adhered to the concept of customer first, to provide customers with the best products and services. At present, the company has realized the large-scale production of diamond and aluminum nitride related products, the existing diamond wafer Ra<1nm, diamond hot sinks thermal conductivity 1000-2000W/m.k, and GaN on diamond, Diamond on GaN, diamond-based aluminum nitride and other products. And has been widely used in 5G base stations, lasers, new energy vehicles, new energy photovoltaics and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message