![]() With the advent of various new renewable energy sources and the emerging need to deliver and convert energy more efficiently, power electronics have received unprecedented attention in recent years. For the last several decades, Si- based power devices have played a dominant role in power conversion electronics. Wide bandgap semiconductor material based power electronics, such as those employing GaN and SiC, are expected to handle more power with higher efficiency than Si-based ones. GaN exhibits higher saturation velocity than Si. However, the thermal conductivity of GaN is low for power conversion systems. Moreover, it is currently difficult to obtain a thick and high quality GaN layer. SiC has its own native substrate, but it has inferior performance matrices (e.g., Johnson’s figure of merit) versus GaN. In comparison, diamond exhibits most of the critical material properties for power elec- tronics, except for its small substrate size at present. Diamond has a wide bandgap, high critical electric field, high carrier mo- bility, high carrier saturation velocities, and the highest thermal conductivity among all available semiconductor materials.Due to its superior electrical properties, the thickness of the highest quality diamond required to block an equivalent amount of voltage is approximately one-fifth to one-fourth thethicknesses of GaN or SiC. In particular, the superior thermal conductivity of diamond could greatly simplify the design of heat dissipation and hence simplify entire power electronics modules. Therefore, diamond is considered the best material candidate for power electronics in terms of power switching efficiency, reliability, and system volume and weight. However, besides the lack of large area single crystalline diamond (SCD) substrate, SCD is ultra-stable and chemically inert to most reac- tive reagents, due to the strong σ-bonds formed between adjacent carbon atoms, making substitutional doping very difficult. Because of the doping difficulty, the majority of diamond-based diodes reported to date are Schottky diodes.

With the advent of various new renewable energy sources and the emerging need to deliver and convert energy more efficiently, power electronics have received unprecedented attention in recent years. For the last several decades, Si- based power devices have played a dominant role in power conversion electronics. Wide bandgap semiconductor material based power electronics, such as those employing GaN and SiC, are expected to handle more power with higher efficiency than Si-based ones. GaN exhibits higher saturation velocity than Si. However, the thermal conductivity of GaN is low for power conversion systems. Moreover, it is currently difficult to obtain a thick and high quality GaN layer. SiC has its own native substrate, but it has inferior performance matrices (e.g., Johnson’s figure of merit) versus GaN. In comparison, diamond exhibits most of the critical material properties for power elec- tronics, except for its small substrate size at present. Diamond has a wide bandgap, high critical electric field, high carrier mo- bility, high carrier saturation velocities, and the highest thermal conductivity among all available semiconductor materials.Due to its superior electrical properties, the thickness of the highest quality diamond required to block an equivalent amount of voltage is approximately one-fifth to one-fourth thethicknesses of GaN or SiC. In particular, the superior thermal conductivity of diamond could greatly simplify the design of heat dissipation and hence simplify entire power electronics modules. Therefore, diamond is considered the best material candidate for power electronics in terms of power switching efficiency, reliability, and system volume and weight. However, besides the lack of large area single crystalline diamond (SCD) substrate, SCD is ultra-stable and chemically inert to most reac- tive reagents, due to the strong σ-bonds formed between adjacent carbon atoms, making substitutional doping very difficult. Because of the doping difficulty, the majority of diamond-based diodes reported to date are Schottky diodes.

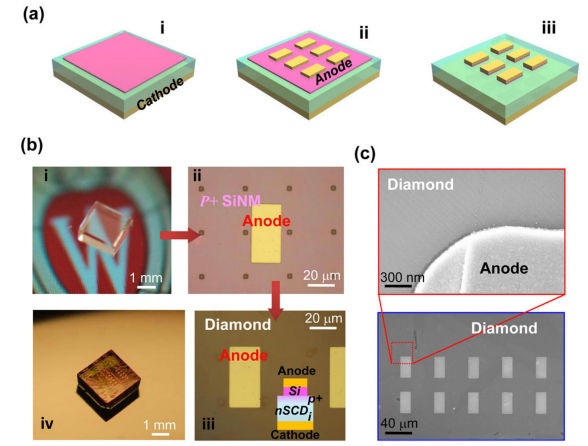

Here we demonstrate a very simple, yet viable method for selective boron doping in natural SCD (nSCD) via an easy thermal diffusion process at a much lower temperature than those used in any other doping methods. We use heavily doped silicon nanomembranes (SiNMs), which are now easily accessible, as our dopant carrying medium. Standalone SiNM, since its first appearance in 2005, has been extensively inves- tigated. The processing of SiNM, including transferring, doping, and bonding, can be readily carried out with conven- tional processing tools. The SiNM is typically released in thin single-crystal silicon sheets, e.g., from a silicon-on-insulator (SOI) wafer, with thicknesses ranging from a few nanometers up to microns. The thinness of SiNM brings in a number of electronic and mechanical properties that are not possessed by its rigid counterparts (i.e., bulk Si). These unique properties have been extensively harnessed in recent years. A summary of the detailed processing methods of nanomembranes, including their creation, manipulation, etc., and their signifi- cant applications can be found elsewhere.

In this work, we first exploit the bonding advantages of SiNMs. In comparison with a regular/bulk Si substrate that is rigid and rather difficult to bond to diamond, the bonding force of SiNMs is much stronger than rigid Si due to its thin thickness. As described earlier, the bonding force increases exponentially with the reduction of Si thickness, which is a unique and important property of flexible SiNM. The ultra- mechanical flexibility of SiNM also allows much more conformal and higher fidelity bonding and better surface roughness tolerance when bonding with diamond, both of which facilitate intimate contacts between SiNM and dia- mond (nearly 100% bonding yield without using any adhe- sives and no limitation on SiNM’s size or shape). Also, due to the thinness of SiNM, we are able to exploit it for dopant carrying. SiNM, like bulk Si, can be heavily doped via con- ventional ion implantation and post-implant thermal anneal- ing without destroying its single crystal structure. Unlike bulk Si, SiNM can be easily heavily doped across its full thickness due to its thinness. A detailed description of the method to realize SiNM full-thickness heavy doping can be found from recent publications.Heavily boron doped thin SiNM was bonded to diamond to serve as the dopant-carrying medium for thermal diffusion in this work. As detailed in the supplementary material (Fig. S1), the prepa- ration and application of SiNM as a dopant carrying medium for diamond are relatively easy and straightforward. It should also be noted that heavily doped SOI wafer is also commer- cially available and that the doping process described here (in supplementary material) can be considerably simplified if using such SOI wafer.

Besides the process simplicity, the SiNM based thermal diffusion doping method leads to effective, uniform, and selective heavy doping in SCD. No graphitization is induced even on the diamond surface as long as it is covered by SiNM. Without involving high temperature or high vacuum furnace, the doping process can be readily realized using conventional rapid thermal annealing (RTA) process, which is widely accessible in comparison with ion implantation and in-situ doping methods. In addition, the doping method proves to be very effective in forming a shallowly doped p- type layer in diamond, which is sufficient for most device applications, while keeping its single crystallinity intact.

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message