Pos:

Home NewsCompany ProfileResearch progress and application of ultra wide band gap semiconductor diamond wafer and heat sinkRecently, hosted by the Talent Exchange Center of the Ministry of Industry and Information Technology and the Management Committee of Nanjing Jiangbei New Area, the second integrated Circuit Industry and Capital Innovation Forum and the Series of Events of Nanjing Innovation Week were held in Nanjing. This event invited relevant government leaders, industry experts, domestic and foreign innovation forces, investment institutions and excellent entrepreneurial teams to discuss the development trend of innovation and entrepreneurship, promote multi-party exchanges and cooperation, and conduct in-depth analysis and extensive discussion on hot and focal issues in the industry.

Zhang Xing, co-founder and CEO of us, was invited to participate in the online and offline communication meeting with the theme of "Sino-German semiconductor industry innovation" in the fourth branch meeting, and the representatives of Infineon, MSG Lithoglas GmbH and Senorics participated together. During the meeting, zhang, as a representative of the wide bandgap semiconductor materials enterprises share the ultra wide band gap semiconductor crystal king kong wafers and the research progress and application of heat sink piece, put forward that the heat dissipation problem of high power devices is to limit its application and the development bottleneck, diamond to its superior performance to become one of the most promising semiconductor materials, The technological process and difficulties of diamond and the solutions to these problems by combination electrodeposition are introduced emphatically.

GaN chip, advanced packaging and other industries are currently paying great attention to the heat dissipation of high-power devices. Diamond is very suitable for making high-power devices due to its excellent properties such as extremely high thermal conductivity, extremely high dielectric breakdown characteristics, extremely high power capacity, low dielectric constant, high saturated carrier speed and high carrier mobility.

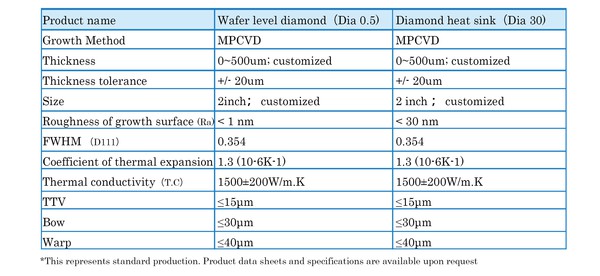

At present, the CVD team has made great progress in the CVD diamond process. The surface roughness of CVD diamond growing surface Ra < 1 nm, which has reached the world's leading level. As an advanced thermal management material, CVD diamond can be applied to military radar, optical module heat sink, laser heat sink, GaN Hemt and other devices, and has a broad application prospect in the future.

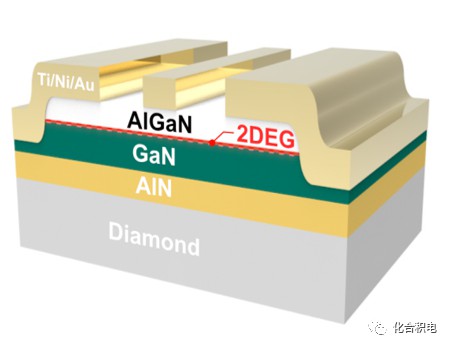

Compared with Si material, GaN is more resistant to high temperature and has higher power density output. Compared with SiC materials, GaN can be applied to high frequency scenarios, and has the cost advantage, so it has a wide range of uses in LED, laser, fast charging, inverter, radio frequency device, etc., but the heat dissipation problem has become one of the bottlenecks restricting the development of GaN. Based on the epitaxial GaN technology of polycrystalline Diamond substrate, CVD makes GaN on Diamond become a reality from an ideal. With the help of the high thermal conductivity of Diamond substrate, the power level of GaN can be greatly improved, the device life can be extended, the reliability can be improved, the manufacturing cost can be reduced, and the cooling effect and performance of GaN devices can be improved.

AlGaN/GaN 2DEG on Diamond

In terms of thermal management,We has launched a series of products, such as wafer grade diamond, diamond heat sink and metallized diamond.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message