Pos:

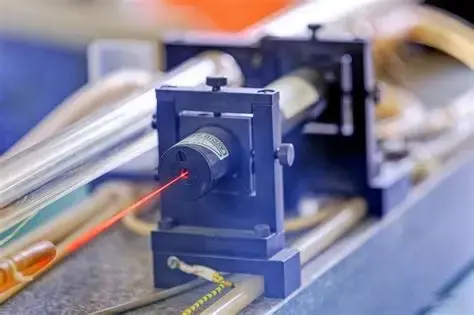

Home KnowledgeTechnologyDiamond Heat Sinks: The Core Thermal Management Solution Empowering Performance Breakthroughs in Semiconductor LasersAs semiconductor lasers evolve toward higher power, greater density, and longer lifespans, thermal management has become a critical bottleneck restricting their performance limits. During high-power operation, non-radiative recombination losses and Joule heating in the active region of laser chips cause a sharp rise in junction temperature, triggering a series of issues such as wavelength red shift, reduced electro-optical conversion efficiency, and increased threshold current—severely compromising device reliability and service life. Leveraging its exceptional thermal properties, diamond heat sinks are transforming from replacements for traditional thermal materials into a core enabler of technological innovation in semiconductor lasers, driving laser applications to expand into more extreme scenarios.

The core advantages of diamond heat sinks stem from their unique material characteristics. At room temperature, diamond exhibits a thermal conductivity of up to 2000-2200 W/m·K. This ultra-high thermal conductivity enables rapid heat dissipation from the chip's active region, reducing the junction temperature by more than 30-50°C and freeing up ample space for power enhancement. Meanwhile, diamond's coefficient of thermal expansion (CTE) is highly compatible with semiconductor chip materials such as GaAs and InP, effectively mitigating thermal stress caused by CTE mismatches during packaging and significantly improving the long-term stability of devices. In addition, its combined properties of high electrical insulation, chemical stability, and mechanical strength allow it to adapt to complex packaging environments and harsh operating conditions, achieving multi-functional integration of heat dissipation, electrical isolation, and structural support.

Diamond heat sinks demonstrate precise adaptability and significant performance improvements across diverse application scenarios of semiconductor lasers. In the field of high-power semiconductor lasers (HPLDs) and bar arrays, the continuous output power of a single laser diode bar has exceeded several hundred watts, resulting in extremely high heat flux density. Diamond heat sinks achieve direct bonding with chips through metallized eutectic soldering or surface activated bonding (SAB) technologies, constructing an efficient primary thermal dissipation pathway. Application data shows that compared with copper-tungsten heat sinks, diamond heat sinks reduce device thermal resistance by 24% and thermal stress by 42%. This not only extends the laser lifespan from several thousand hours to tens of thousands of hours but also enables higher output power or lower operating voltage under the same temperature rise conditions, with electro-optical conversion efficiency optimized by several percentage points.

For edge-emitting lasers (EELs) and vertical-cavity surface-emitting lasers (VCSELs), diamond heat sinks offer more flexible application forms. In the coplanar packaging (C-mount) of single-tube EELs, diamond heat sinks achieve efficient heat dissipation through compact structural design. In high-power VCSEL arrays for 3D sensing and lidar applications, their excellent lateral thermal conductivity effectively homogenizes the temperature of array elements, avoiding the formation of "hot spots" and ensuring the consistency of beam output and wavelength stability. In the pump modules of solid-state lasers and fiber lasers, laser diode modules adopting diamond heat sinks deliver more stable pump light, indirectly enhancing the output stability and reliability of the entire laser system. Additionally, diamond window wafers can serve as output windows for high-power lasers, withstanding extremely high power densities due to their low absorption characteristics. In the emerging field of ultraviolet (UV) and deep ultraviolet (DUV) lasers, diamond combines high thermal conductivity with UV transparency, acting as a "transparent heat sink" that simultaneously fulfills the functions of heat dissipation and light output window—providing a new path for performance breakthroughs in AlGaN-based devices.

In the future, diamond heat sinks will develop toward multi-functional integration and deep fusion. On-chip thermal integration technology is expected to realize heterogeneous integration of laser chips with diamond thin films during the manufacturing stage, constructing an "in-situ" ultra-high-efficiency thermal dissipation structure. Opto-thermal-electrical co-design will fully utilize the tunable optical properties of diamond to achieve synergistic optimization of thermal management, optical confinement, and electrical isolation. The combination of wide-bandgap semiconductors and diamond (e.g., GaN-on-Diamond) is emerging as the ultimate solution for realizing ultra-high power density optoelectronic devices, which will drive technological revolutions in fields such as high-power lidar and 5G/6G communications. With the maturation of preparation processes and the reduction of costs, diamond heat sinks will transform from a "performance upgrade option" into a "standard component" for high-power semiconductor lasers, continuously illuminating the cutting-edge paths of laser technology innovation and industrial applications.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), which has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message