Pos:

Home KnowledgeTechnologyDiamond Heat Sink Substrates: The "Thermal Management Revolution" for Leapfrog Improvements in Laser PerformanWith the rapid development of laser technology, lasers are increasingly emerging as the core engine of modern industry and cutting-edge science and technology, spanning applications from precision micromachining and high-power weapon systems to optical fiber communications and medical devices. However, as laser power continues to rise and application scenarios become more stringent, thermal management has become a critical bottleneck restricting laser performance, reliability, and service life. Against this backdrop, diamond heat sink substrates—boasting extraordinary properties such as ultra-high thermal conductivity, excellent electrical insulation, and superior mechanical strength—are spearheading a profound "thermal management revolution", delivering a disruptive solution for breakthrough improvements in laser performance.

The core of a laser lies in its pump source (e.g., laser diode chips) and gain medium. During high-power operation, a large portion of the input electrical energy (typically over 50%) is converted into waste heat, causing a sharp rise in chip junction temperature. This temperature increase triggers a cascade of adverse effects. Therefore, efficiently and rapidly dissipating heat from the laser’s active region is the cornerstone of maintaining high-efficiency, stable, and long-lifetime laser operation. Traditional heat sink materials such as copper (with a thermal conductivity of approximately 400 W/m·K) and copper-tungsten alloys (180–240 W/m·K) are no longer capable of meeting the thermal management demands of lasers with kilowatt-level, megawatt-level, or even higher power densities.

Diamond heat sink substrates achieve "source thermal reduction" by acting as the primary heat dissipation pathway, either through direct bonding to laser chips (e.g., metallized eutectic bonding, surface-activated bonding) or tight packaging.

High-Power Semiconductor Lasers (HPLD) and Laser Bar Arrays

This is the most mature and high-impact application field for diamond heat sinks. A single high-power laser diode bar can achieve a continuous output power of several hundred watts with extremely high heat flux density. Integrating diamond substrates as the chip’s substrate or heat sink delivers the following benefits:

Significant Junction Temperature Reduction: Compared with copper heat sinks, junction temperature can be lowered by over 30–50°C.

Enhanced Output Power and Efficiency: Under the same temperature rise conditions, higher injection currents are allowed to boost output power; alternatively, operating voltage can be reduced to improve electro-optical conversion efficiency (typically by several percentage points).

Improved Beam Quality and Spectral Characteristics: More uniform temperature distribution mitigates the thermal lensing effect and stabilizes the output wavelength.

Extended Service Life: Lifespan is increased from thousands of hours to tens of thousands of hours, significantly reducing maintenance costs.

Edge-Emitting Lasers (EEL) and Vertical-Cavity Surface-Emitting Lasers (VCSEL)

For single-chip EELs, diamond heat sinks can be used in C-mount packaging to achieve high-efficiency heat dissipation. In the VCSEL field—especially for high-power-density VCSEL arrays used in 3D sensing and lidar applications—diamond’s excellent lateral thermal conductivity effectively homogenizes the temperature across individual array elements, preventing "hotspots" and ensuring consistent and stable array emission.

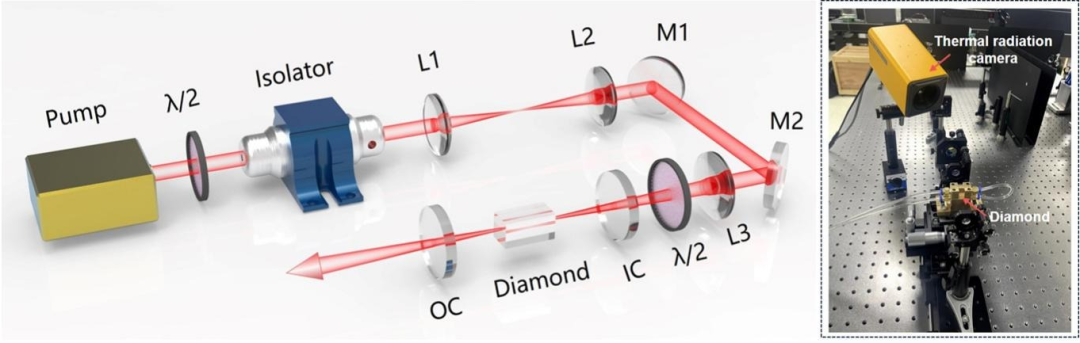

Pump Modules for Solid-State Lasers and Fiber Lasers

As the core pump source for high-power solid-state lasers (e.g., diode-pumped solid-state lasers, DPSSL) and fiber lasers, laser diode modules integrated with diamond heat sinks provide more stable and reliable pump light, thereby indirectly enhancing the performance and reliability of the entire laser system. Diamond windows can also be used as output windows for high-power lasers; their high thermal conductivity and low absorption rate enable them to withstand ultra-high power densities.

Emerging Ultraviolet (UV) and Deep Ultraviolet (DUV) Lasers

UV lasers based on materials such as aluminum gallium nitride (AlGaN) face more acute thermal challenges. Diamond not only has ultra-high thermal conductivity but also exhibits good transparency in the UV band. It can serve as a "transparent heat sink" that simultaneously fulfills dual functions of heat dissipation and light output window, opening up new avenues for the development of deep ultraviolet devices.

The role of diamond in the laser industry is evolving from a simple "heat sink" to a "multi-functional integrated substrate". Future development directions include:

On-Chip Thermal Management Integration: Exploring heterogeneous integration of diamond thin films directly beneath the gain region during laser chip fabrication to achieve "in-situ" ultra-efficient heat dissipation.

Optical-Thermal-Electrical Co-Design: Leveraging diamond’s high thermal conductivity, high electrical resistivity, and tunable optical properties (e.g., color center engineering via doping) to design novel laser architectures, enabling synergistic optimization of thermal management, optical confinement, and electrical isolation.

Integration of Wide-Bandgap Semiconductors with Diamond: The combination of third-generation semiconductors (e.g., GaN-on-Diamond) and diamond is regarded as one of the ultimate solutions for realizing ultra-high-power-density electronic and optoelectronic devices, which will greatly advance the development of high-power lidar, 5G/6G radio frequency devices, and other fields.

The application of diamond heat sink substrates marks the evolution of laser thermal management technology from "incremental improvement" to "transformative innovation". It will continue to drive laser technology toward a future of higher power, greater precision, and enhanced performance, illuminating the path for human exploration and innovation.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), which has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message