Pos:

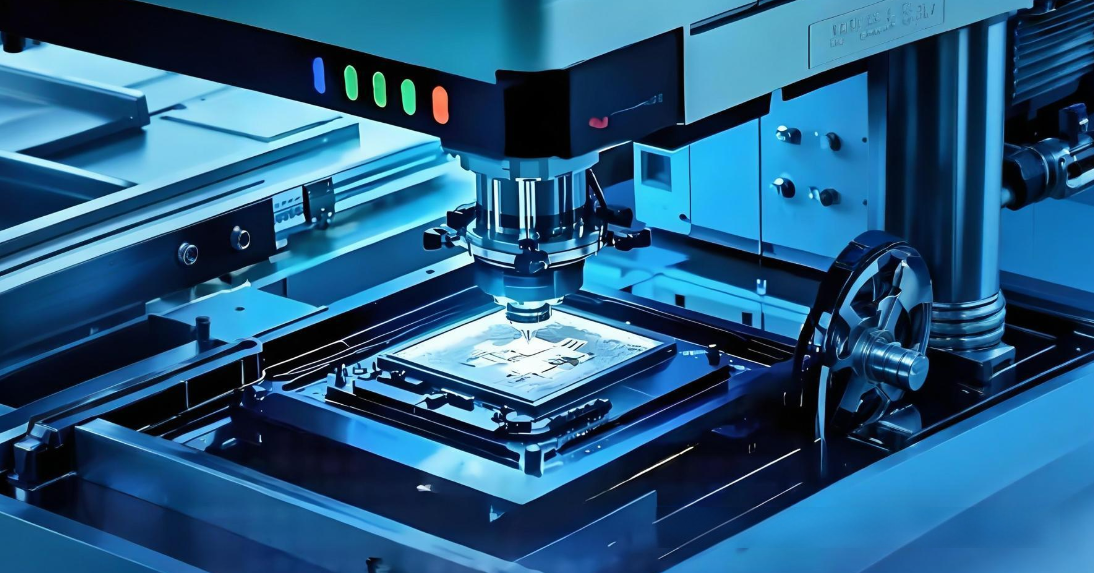

Home KnowledgeTechnologyDiamond Heat Sink: The Core Solution to Thermal Management Challenges in Advanced Lithography MachinesAs semiconductor processes evolve to the 3nm and below nodes, lithography machines, the core equipment for chip manufacturing, are facing unprecedented thermal management challenges. EUV lithography machines require the cooling water temperature fluctuation to be controlled within ±0.001℃, and traditional copper-based heat dissipation materials can no longer meet the heat dissipation demands under ultra-high power density. Relying on its exceptional physical properties, the diamond heat sink has become an ideal solution to break through the heat dissipation bottleneck of lithography machines.

Diamond is naturally insulating, eliminating the risk of electric leakage; meanwhile, it features high hardness, radiation resistance, and high temperature resistance (>1000℃), making it suitable for the long-term stable operation of lithography machines in high-power, high-frequency, and high-temperature environments.

1. Heat Dissipation for Laser Light Source Systems

The laser light source of a lithography machine is the primary source of heat generation. Using diamond heat sinks as the heat dissipation substrate for laser diodes can reduce the laser junction temperature by 30-50%, significantly improving the stability of output power and the lifespan of devices. Compared with traditional SiC-based GaN devices, diamond-based GaN devices can achieve a 20% improvement in RF performance, and the temperature change from the GaN channel to the bottom of the substrate is reduced by 80℃.

2. Thermal Management for Optical Systems

Optical components such as the projection objective lens of lithography machines have extremely high requirements for temperature stability. Diamond heat sinks are integrated on the back of optical modules through low-temperature bonding technology, enabling temperature control precision of ±0.002℃.

3. Wafer Stage Temperature Control

The wafer stage needs to maintain extremely high temperature stability during the exposure process. As the heat dissipation substrate of the wafer stage, diamond heat sinks can quickly conduct away high-density heat, ensuring that the temperature fluctuation of the wafer surface is controlled within ±0.01℃, thus guaranteeing the exposure uniformity of photoresist and the precision of patterns.

The surface of diamond heat sinks undergoes precision polishing and metallization treatment. Water-guided laser processing technology can achieve a surface roughness of Ra≤0.3μm with a heat-affected zone of less than 5μm, completely avoiding the formation of a graphitization layer. Metallization with transition layers such as titanium and chromium enables high-strength bonding with chips, with a bonding strength of over 50MPa.

Diamond heat sinks are directly bonded to chips using a low-temperature bonding process, shortening the heat conduction path. Nanoscale interface regulation reduces the chip thermal resistance by 28.5%, providing a new approach to solve the heat dissipation challenges of 3D integrated chips.

Alternatively, diamond-copper composite heat sinks can be constructed, which combine high thermal conductivity with good processability. By adjusting the diamond volume fraction, high thermal conductivity and adjustable thermal expansion are achieved to meet the requirements of system heat dissipation and assembly processes. The thermal conductivity of diamond/copper composites can reach 630.3W/m·K, with a bending strength of up to 283.7MPa, and the thermal conductivity only decreases by 1% after 100 thermal shock cycles.

Another option is to integrate diamond heat sinks with microchannel liquid cooling systems to build an active heat dissipation solution. Through the circulation of cooling fluid in microchannels, ultra-high heat flux density dissipation capacity is achieved. This solution can support the power consumption of a single cabinet in AI data centers to increase from 30kW to 100kW, and GPUs must be equipped with diamond heat sinks.

With its ultra-high thermal conductivity, excellent thermal expansion matching, and electrical insulation, the diamond heat sink has become the optimal solution for heat dissipation in high-power electronic equipment such as lithography machines. Through breakthroughs in key technologies including MPCVD technology, zero-warpage processes, and microchannel structure design, diamond heat sinks have achieved stable mass production and been successfully applied in key components of lithography machines such as laser light sources, optical systems, and wafer stages. As semiconductor processes advance to more advanced nodes, diamond heat sinks will play an increasingly important role in the thermal management of lithography machines, providing strong material support for the technological progress of the semiconductor industry.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond composite materials,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), which has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message