Pos:

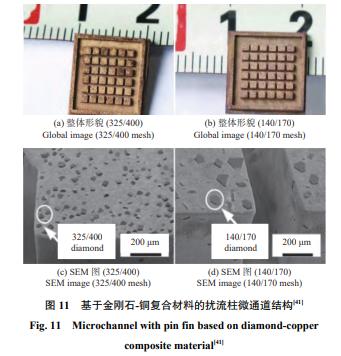

Home KnowledgeTechnologyApplication of Diamond composite materials in Microchannel Heat DissipationDiamond-reinforced metal matrix composites can enable heat sinks to have larger sizes and thicknesses at relatively low costs. Moreover, the thermal expansion coefficient of the composites can be adjusted by modifying the proportion of the diamond reinforcement phase. Leveraging these advantages, researchers have turned their attention to diamond-reinforced metal matrix composites and attempted to fabricate surface microchannel structures on such materials. They successfully prepared a copper-based diamond composite with a thermal conductivity of 614.87 W/(m·K), and utilized the UV-LIGA process to create cross-shaped microchannels on the composite surface, where the microchannels have a width of 250 μm and a depth of 500 μm, as shown in the figure.

A copper-boron matrix diamond composite heat sink with a thermal conductivity of 850 W/(m·K) was prepared by the gas pressure infiltration method, as shown in Figure 12. Its heat dissipation performance was tested under three cooling modes—natural cooling, forced air cooling, and forced water cooling—by comparing it with pure copper and pure aluminum heat sinks of the same size. The experimental results indicate that as the heat source power increases, the heat dissipation effect of the composite becomes more significant. Under the forced water cooling mode, the composite fin heat sink exhibits a lower overall temperature and a more uniform temperature distribution.

The laser direct energy deposition (LDED) technology was employed to directly print copper matrix diamond composite microchannel heat sinks through metal additive manufacturing. The diamond used had a particle size of 105 μm, a surface coated with a TiO₂-TiC layer, and a volume fraction of 25%. The thermal conductivity of the composite reached 330 W/(m·K). This study provides a new approach for the preparation of microchannel heat dissipation devices based on diamond-reinforced metal matrix composites.

With the development of composite synthesis processes, the performance of the obtained diamond-reinforced metal matrix composites has been continuously improved. Although the research on microchannel heat dissipation based on diamond-reinforced metal matrix composites is still in its initial stage, it has already achieved efficient heat dissipation with a heat flux density of 1.0 kW/cm² or higher, indicating extremely broad application prospects.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.Among these, diamond-copper composite materials have been applied in fields such as AI chips, servers, optical communication, and lasers.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message