Nowadays, the semiconductor industry is in a critical period of transition, the semiconductor field dominated by silicon is facing a bottleneck of high power density, high frequency, high temperature, high radiation and other conditions; the third generation of semiconductors along the way to GaN and SiC as the representative of the development of new materials to promote the power devices continue to move forward to the direction of high power, miniaturization, integration and multi-functionality, but the key characteristics of the heat dissipation, energy efficiency and other key features are still the future development direction

Diamond refers to raw, unpolished diamonds. So, as a new semiconductor material that has come into the limelight, what is the appeal of “diamond” chips? Behind the infinite possibilities, progress and challenges exist side by side.

Known as “nature's hardest substance” diamond, not only amazing hardness, but also has excellent thermal conductivity, very high electron mobility, with high pressure, large radio frequency, low cost, high temperature and other multiple excellent performance parameters, as well as other excellent physical properties.

In addition, diamond has excellent physical properties, with good light transmission and refractive index in the optical field, suitable for the research and development of optoelectronic devices; electrically, its insulating properties and dielectric constant enable it to play a stable role in complex circuits; in terms of mechanical properties, high strength and wear resistance to ensure that the chip is able to withstand extreme working conditions.

These properties make diamond show great potential in the field of chip manufacturing, and are often used for heat dissipation in high power density and high frequency electronic devices. It plays an important role in the development of 5G/6G communications, microwave/millimeter wave integrated circuits, and detection and sensing. Diamond semiconductor is considered to be a promising new semiconductor material, and is regarded as the “ultimate semiconductor material” by the industry.

By using diamond electronics, not only can the thermal management needs of conventional semiconductors be alleviated, but these devices are also more energy efficient and can withstand higher breakdown voltages and harsh environments.

For example, in electric vehicles, diamond-based power electronics enable more efficient power conversion, longer battery life, and shorter charging times; in telecommunications, there is a growing demand for high-frequency and high-power devices, especially in the deployment of 5G and higher-level networks. Single-crystal diamond substrates provide the necessary thermal management and frequency performance to support next-generation communications systems, including RF switches, amplifiers, and transmitters; and in consumer electronics, single-crystal diamond substrates can drive the development of smaller, faster, and more efficient components for smartphones, laptops, and wearable devices, leading to new product innovations and improving the overall performance of the electronic device market.

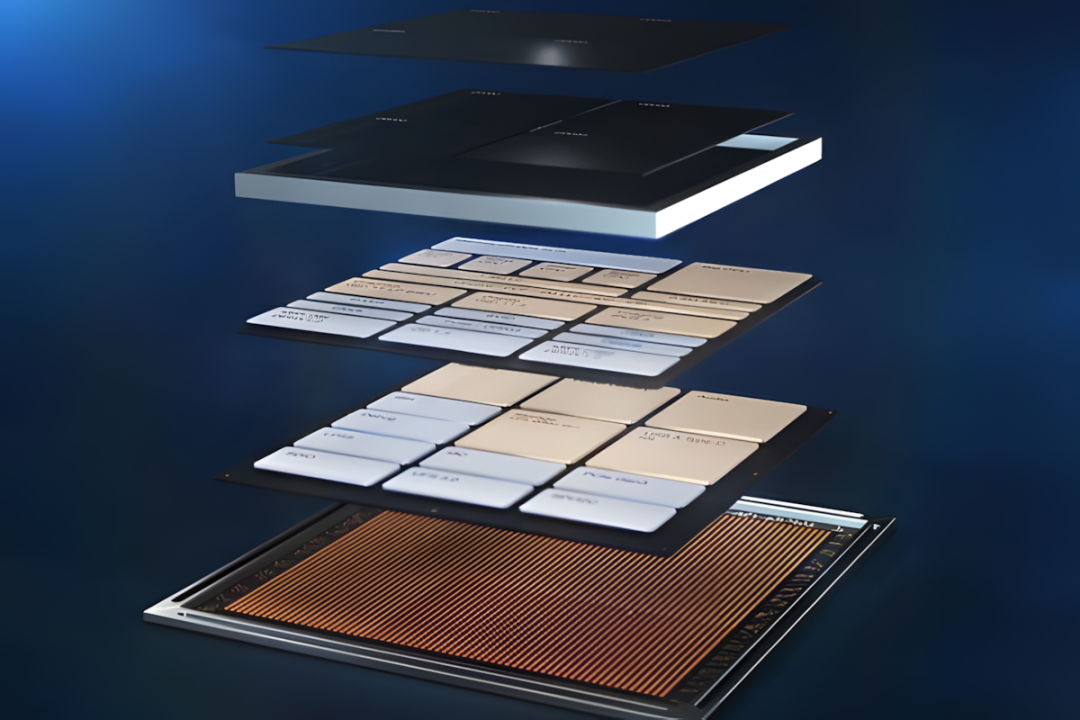

According to market research firm Virtuemarket, the global diamond semiconductor substrates market was valued at USD 151 million in 2023 and is expected to reach USD 342 million by the end of 2030. It is forecas to grow at a CAGR of 12.3% from 2024-2030. Driven by characteristic advantages and broad prospects, diamond has already demonstrated great potential and value in several segments of the semiconductor industry chain. From heat sinking, packaging to micro-nanofabrication, to BDD electrodes and quantum technology applications, diamond is gradually penetrating into various key areas of the semiconductor industry, promoting technological innovation and industrial upgrading.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds, and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows, diamond hetero junction integrated composite substrates, etc. Among them, the thermal conductivity of diamond heat sinks is 1000-2200W/(m.k), and the surface roughness of diamond wafer Ra<1nm. lt has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message