Lasers operating in the 1300 and 1550nm wavelength band, capable of producing high output power that can be coupled into single-mode fibers, are of considerable interest for next-generation fiber lasers and amplifiers.1, 2 The major practical application of these devices is increased throughput of fiber-optic communication systems and extending the wavelength range of eye-safe, high-brightness laser sources to meet emerging requirements in biomedicine, industrial processing, night vision illumination, and so forth. High-power lasers emitting at these wavelengths are also expected to find wide use in frequency-doubled lasers emitting in the visible optical range to replace existing sources with low efficiency and low output power.3

Indeed, in the 1300–1500nm waveband the maximum output power that can be coupled into a single-mode fiber with existing edge-emitting lasers is about 0.5W,4 a factor of two to three lower than with gallium arsenide (GaAs)-based edge-emitting lasers operating around 1μm. This is because the material gain of indium aluminum GaAs/indium phosphide (InAlGaAs/InP) quantum wells (QWs)—in which electrons and holes (positive charge carriers) recombine to produce photons—is smaller than the material gain of GaInAs/GaAs QWs. One effective way of increasing output power in combination with high-quality beams involves using optically-pumped vertical external cavity surface-emitting lasers (VECSELs). We previously developed VECSELs emitting in the 1300 and 1550nm range that show output power levels in excess of 1W.5 This performance improvement is due to the application of AlGaAs/GaAs wafer-fused distributed Bragg reflectors (DBRs)—i.e., mirrors—to replace InP-based DBRs with inferior optical and thermal properties.

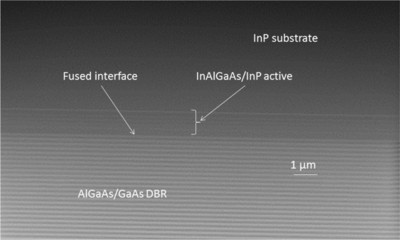

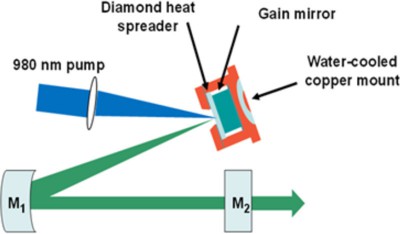

We subsequently used the wafer-fusion process to produce defect-free large-area gain mirrors. In this method, we bring the InAlGaAs/InP active wafer into contact with the GaAs/AlGaAs DBR mirror wafer at 600°C and apply pressure.6 After cooling, we complete the process by selectively etching the InP wafer (see Figure 1). We combined these gain mirrors with intracavity , and with curved and output coupling mirrors, to build optically pumped VECSELs: see Figure 2. 7–10

Figure 1. Scanning electron micrograph of a wafer-fused gain mirror.

Figure 2. Schematic of the cavity of a vertical external surface-emitting laser (VECSEL). M1: Curved mirror. M2: Output coupling mirror.

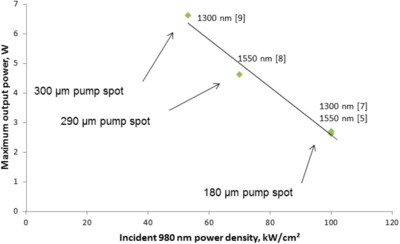

Figure 3 summarizes the maximum output power levels reached with 1300 and 1550nm wafer-fused VECSELs with different pump-spot sizes. The maximum output power scales with spot size: a 2.5 increase in size corresponds to 2.5 increase in output power. In addition, higher output power is reached at lower pump-power density levels because of increased laser efficiency. We found that VECSELs with a lower pump-spot size diameter of 180μm show a very good M2 (beam quality factor, or degree of imperfection) of less than 1.5. We used these devices for pumping Raman fiber lasers that achieved 1.1W output power at 1380nm with pumping at 1300nm10 and 0.5W at 1600nm with pumping at 1500nm.11 We employed higher-power devices with larger pump-spot sizes of around 300μm in intracavity frequency-doubled VECSELs that exhibited 1W output power at 785nm (1570nm doubled)8 and 3W at 650nm (1300nm doubled).9

Figure 3. Maximum output power of wafer-fused VECSELs versus the incident 980nm power density.

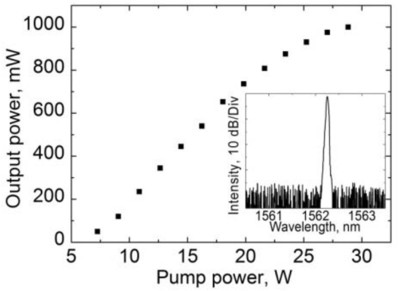

Generally, in VECSELs with intracavity diamond heat-spreaders, the emission spectra have multiple emission lines resulting from the diamond Fabry-Pérot etalon. Recently, we modified the VECSEL cavity by introducing an additional intracavity wavelength selection mechanism that enabled 1W single-frequency operation at 1562nm (see Figure 4) with 18MHz line-width and coherence length longer than 5km.12

Figure 4. Output power for single-frequency regime as a function of pump power.

In conclusion, our wafer-fusion fabrication approach has produced state-of-the-art performance of 1300–1500nm waveband optically-pumped VECSELs. We expect this technology to boost the development of new types of fiber lasers and amplifiers, frequency-doubled lasers, and high-power single-frequency lasers in the important wavelength range of low-loss single-mode silica fibers. Further design optimization of our wafer-fused gain mirrors should enable an increase in output power to 10W and more.

We have now been diamond heat sink, wafer level diamond products, used in semiconductor lasers, resistor, large power LED chip, high power devices, gallium nitride epitaxial growth, satellite hot plate reinforcement, power components, microwave, millimeter wave radar (MMIC) operating power amplifier, transmitters, RF power amplifier, filter, high power laser weapons, etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message