The quality of diamond films and the boron concentration in the films were analyzed and characterized using SEM, Raman spectroscopy, SIMS, and Hall effect measurements.

For the boron-doped diamond film with a thickness of 700 nm, the boron concentration (measured by Secondary Ion Mass Spectrometry, SIMS) and Hall mobility (at 20°C) were determined to be 10¹⁸/cm³ and 80 cm²/(V·s), respectively, while the carrier concentration (measured via Hall effect) was 10¹⁶/cm³.

The experimental results indicate that boron doping can improve the quality of diamond films and enhance their oriented growth. Additionally, the introduction of boron acts as a catalyst, increasing the film growth rate.

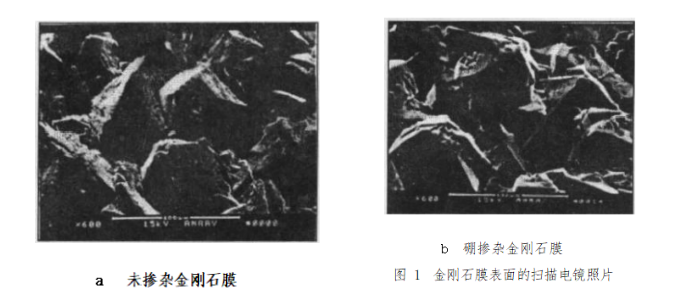

Figure 1 shows the scanning electron microscopy (SEM) images of the diamond film surface. In the figure, panels (a) and (b) represent the surface morphologies of the undoped and boron-doped diamond films, respectively. Both films exhibit densely distributed square or rectangular crystal facets with relatively uniform arrangement on the Si(100) substrate, featuring a compact structure and relatively intact crystal facets. The films are polycrystalline, composed of oriented small grains with a size of approximately 2 μm, thus achieving high-quality locally heteroepitaxial oriented diamond films.

Figure 2 presents the relationship between the Raman spectra (of both Si and the diamond film) and the measurement angle, obtained by rotating the sample. The results indicate that the boron-doped diamond film remains a highly oriented heteroepitaxial diamond film, suggesting that boron doping exerts little influence on the epitaxial growth of the diamond film.

Raman spectroscopy is highly sensitive to structural changes in diamond films and stands as one of the most powerful tools for analyzing diamond films. After high-concentration boron doping, significant changes occur in the Raman spectrum, indicating substantial structural alterations in the diamond film.

Figure 3 displays the Raman spectra of the diamond films, where spectrum (a) corresponds to the undoped sample, and spectra (b), (c), (d), (e), and (f) correspond to boron-doped samples. For sample (a), in addition to the characteristic diamond peak at 1332 cm⁻¹, there is an extremely broad peak at 1550 cm⁻¹. In contrast, samples (b) and (c) exhibit only a sharp characteristic peak at 1332 cm⁻¹, with the peak at 1550 cm⁻¹ essentially disappearing.

A comparison of the Raman spectra between doped and undoped diamond films reveals that the broad, weak peak at 1550 cm⁻¹ (attributed to amorphous carbon in the undoped diamond film) vanishes under low boron doping concentrations (10¹⁸ cm⁻³ and 10¹⁹ cm⁻³). This demonstrates that the prepared boron-doped diamond films possess high quality, consistent with the boron doping effect. Specifically, low-concentration boron doping is beneficial for improving the lattice structure of diamond films and enhancing their overall quality.

However, with the increase in boron doping concentration—such as (d) 10²⁰ cm⁻³, (e) 10²¹ cm⁻³, and (f) 5×10²¹ cm⁻³—the characteristic peak of diamond at 1332 cm⁻¹ shifts toward lower wavenumbers and exhibits asymmetric broadening. The maximum shift reaches 7.7 cm⁻¹, and the broadening (maximum full width at half maximum, FWHM) is 14 cm⁻¹. Additionally, the peak at 1200 cm⁻¹ (caused by disordered bonding) intensifies, indicating an increase in the disordered phase of the diamond film. The increase in the FWHM of the 1332 cm⁻¹ characteristic peak suggests a rise in dislocation density, which is mainly concentrated at grain boundaries and promotes the relaxation of grain boundaries. Defects in the film, such as dislocations and vacancies, tend to move along grain boundaries, generating tensile stress.

Generally speaking, impurities in the film induce intrinsic compressive stress, while defects (e.g., vacancies, dislocations, grain boundaries) generate tensile stress. The internal stress in the diamond film causes a difference between the position of the characteristic peak in the diamond Raman spectrum and the standard 1332 cm⁻¹ peak of high-quality natural single-crystal diamond. Under compressive stress, the diamond Raman peak shifts to higher wavenumbers; under tensile stress, it shifts to lower wavenumbers. The downward shift of the characteristic Raman peak of doped diamond with increasing boron doping concentration indicates that the tensile stress in the boron-doped diamond film increases. The total stress is tensile stress, and both stress and strain strengthen as the boron doping concentration rises. When the boron concentration in the film increases from 0.1% to 1.6%, the internal stress increases from 0.6 GPa to 16 GPa. At low boron doping concentrations, the short-range nature of interatomic interactions leads to grain boundary relaxation, which generates stress. With further increases in doping concentration (i.e., heavy doping), internal stress is mainly caused by the increase in defect density and the hindrance of grain boundary migration. When the substrate temperature exceeds 850 °C, boron diffuses, causing the coalescence and aggregation of holes, which can reduce internal stress. However, since further migration of diffusion-induced relaxation increases internal stress, the overall reduction in film stress is negligible.

Under the action of internal stress, the diamond film undergoes deformation. The variation of strain with boron doping concentration is consistent with that of stress—both increase as the boron doping concentration rises. Experiments show that when the boron doping concentration is 5×10²¹ cm⁻³, the maximum deformation of the film reaches 1.72%. Strain and deformation simultaneously alleviate stress, and a balance is eventually achieved. If the strain energy exceeds the interface energy between the film and the substrate grains, the film will crack or peel off.

Under tensile stress, the lattice constant of diamond changes, and this change is also related to the boron concentration. High-resolution XRD analysis reveals that the lattice constant increases with increasing boron doping concentration, and this increase is more significant in HFCVD than in MWCVD. When the boron doping concentration is 5×10²¹ cm⁻³, the lattice constant becomes 0.3574 nm, which is a 0.2% increase compared to the 0.3566 nm lattice constant of natural diamond.

SEM and XRD analyses further indicate that the grain size also changes with the doping concentration: as the doping concentration increases, the grain size decreases, the density of grain boundaries in the film increases, and the stress in the film rises.

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message