Pos:

Home KnowledgeTechnologyBoron-doped single-crystal diamond has great potential as the future of semiconductor devicesWhen a small amount of boron or phosphorus impurities are doped into diamond, in addition to possessing all the properties of conventional diamond, it also endows diamond with semiconductor characteristics — a crucial step for the application of diamond in electronic components.

Boron-doped diamond has increasingly become a research and development hotspot in functional diamond due to its excellent electrochemical performance and thermal stability. Pure diamond is an insulator with no free electrons in its crystal lattice; it has a band gap of 5.5 eV and a resistivity generally reaching 10¹³ Ω·cm at room temperature. In contrast, boron-doped diamond is a semiconductor material, and some of its properties far surpass those of monocrystalline silicon and other wide-band-gap semiconductor materials. Relevant research findings indicate that the AC impedance of boron-doped diamond is relatively large at low frequencies — especially when the AC frequency is approaching 0, the AC impedance tends to be infinite. At high frequencies, however, its AC impedance approaches 0.

Compared with conventional diamond, the surface initial oxidation temperature of boron-doped single-crystal diamond is increased by approximately 180℃. When insulated at 1000℃ for 30 minutes in an air medium, the wear ratio of conventional single-crystal diamond decreases by three-fifths, while that of boron-doped single-crystal diamond only decreases by one-third. This indicates that the heat resistance of boron-doped single-crystal diamond is better than that of conventional single-crystal diamond.

The oxidation resistance of boron-doped diamond is also related to the boron content inside the crystal. As the boron content in the diamond crystal increases, the surface initial oxidation temperature also rises accordingly. However, the boron content in diamond is not the higher the better. When the boron content in diamond is too low, its effect on improving and enhancing the oxidation resistance of the diamond crystal is not obvious; when the boron doping amount is too high, the oxidation resistance of diamond deteriorates.

Boron-doped diamond has excellent wear resistance and grindability, and can be used to grind hard and tough materials. Generally, it can be applied as wear-resistant coatings, drill bits, abrasives, cutting tools, etc. Experiments show that the grinding ratio of self-sharpening boron-doped diamond is 22% higher than that of ordinary diamond, the rising slope of spindle power is 38% smaller, the grinding process is more stable, the bonding agent has stronger holding force, and the grinding wheel can maintain continuous sharpness.

Generally speaking, the mechanical strength, compressive strength, and other properties of boron-doped diamond are all better than those of conventional diamond. Existing reports show that after vacuum calcination, the static pressure strength of boron-doped diamond decreases to 98.39% of its original strength, and the reduction range is much smaller than that of ordinary diamond — this indicates that the thermal stability of boron-doped diamond is significantly superior. The static pressure strength of boron-doped single-crystal diamond at different temperatures in air is higher than that of conventional single-crystal diamond, and the reduction range of strength is smaller, demonstrating better thermal stability. This is because boron atoms form new C-B bonds with carbon atoms inside the crystal, and there are no extra valence electrons to bond with external electron-deficient atoms, resulting in an extremely stable crystal state.

Impact toughness measurement is one of the important methods to test the quality level of diamond. The impact toughness values of boron-doped single-crystal diamond at different temperatures are all higher than those of conventional diamond, and the reduction range of impact toughness is smaller throughout the tested temperature range. At the same time, black boron-doped diamond tools have good impact toughness; for example, boron-doped diamond turning tools are less likely to experience edge chipping during intermittent cutting under load.

As the hardest substance in nature, diamond possesses high hardness, high strength, and other physical and chemical properties. On this basis, boron doping converts it from an insulator to a semiconductor with semiconductor characteristics. Meanwhile, its excellent thermal stability and outstanding mechanical properties expand its applications in the fields of industry and science and technology. With the continuous advancement and development of technology, boron-doped diamond has great potential as the future of semiconductor devices.

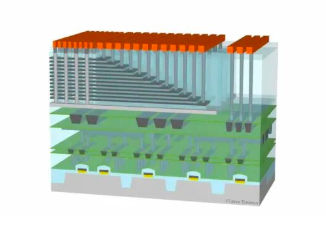

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message