Pos:

Home KnowledgeTechnologyApplication of Boron-Doped Diamond Probe Chip in High-Resolution Electrical Characterization via Reverse-Probe Sample ScIn the era where the size of semiconductor devices continues to shrink below 10 nanometers, electrical characterization technologies are facing severe challenges: although traditional Scanning Probe Microscopes (SPMs) can achieve nanoscale resolution, their operation that relies on manual probe replacement severely limits measurement efficiency. Especially for technologies like Scanning Spreading Resistance Microscopy (SSRM), the probe must simultaneously meet the requirements of ultra-high mechanical strength (withstanding a contact pressure of 10 GPa), nanoscale sharpness (tip radius < 5 nm), and high electrical conductivity. However, the existing Coated Diamond Tips (CDTs) and Full Diamond Tips (FDTs) all have performance shortcomings. More problematically, the improvement of probe sharpness is often accompanied by increased wear, which further intensifies the need for frequent replacement.

To address this bottleneck, researchers have innovatively proposed the Reverse-Probe Sample Scanning Probe Microscope (RTS SPM) architecture—fixing the sample on a cantilever without a probe to scan a fixed probe array, thereby achieving high-throughput measurement through rapid probe switching. Nevertheless, the core bottleneck of this technology lies in the lack of a suitable probe chip: the existing silicon-based array probes have insufficient sharpness, and the preparation process of traditional single-tip diamond probes cannot be directly applied to high-density array integration.

The preparation process of the new probe chip is as follows: first, an inverted pyramid silicon mold is prepared by KOH anisotropic etching; then, a boron-doped diamond film is grown; next, array release is achieved by combining a metal electroplated support film and selective silicon substrate etching; finally, nanoscale sharpened multi-tip structures are generated on the pyramid substrate through self-patterned dry etching. After process optimization, the probe array density reaches 792 tips per chip, the minimum tip radius is 2.7 nm, and the spacing of 25-30 μm meets the safety scanning requirements of the RTS cantilever.

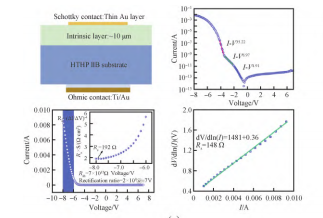

The research results show that the High-Performance Full Diamond Tip (HFDT) chip exhibits an excellent dynamic range (10¹⁶-10¹⁹ carriers/cm³) in the measurement of p-type silicon step calibration samples, confirming its electrical conductivity and mechanical stability. In the GaAs nanoridge waveguide structure, the HFDT probe successfully resolved the nanoscale heterointerfaces. The comparative experiment with the CDT chip is even more convincing: when measuring a FinFET with a 28 nm gate length, the HFDT chip reduced the gate width measurement error from the blurred imaging of the CDT to an accurate 27 nm, and clearly presented the source-drain epitaxy (S/D epi) doping diffusion profile, which is crucial for device modeling.

The breakthrough of this research lies in the first successful transplantation of HFDT technology to the RTS probe chip architecture. It solves film stress deformation through a four-anchor design and realizes large-scale nanoscale tip preparation using self-patterned etching. Compared with traditional CDT chips, the HFDT chip improves the SSRM spatial resolution to a level equivalent to that of conventional SSRM while retaining the 5-fold throughput advantage of the RTS technology.

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message