Pos:

Home KnowledgeTechnologyElectrical Properties of High-Mobility Boron-Doped Single Crystal Diamond via Microwave Plasma Chemical Vapor DepositionBoron (B) is the most commonly used acceptor impurity in diamond. Its low activation energy (0.37 eV) allows for effective electrical manipulation of Boron-Doped Single Crystal Diamond, promising applications in high-power electronics, radio frequency power amplifiers, and deep ultraviolet optoelectronics.

The electrical properties of the samples were tested at room temperature using the four-point van der Pauw method. Based on the test results, the carrier concentration and mobility of the samples were plotted as a function of the boron-to-carbon atomic ratio in the feed gas, as shown in Figure 4(a). The results show that as the boron-to-carbon atomic ratio in the feed gas increases, the hole concentration in the Boron-Doped Single Crystal Diamond film increases, while the mobility exhibits the opposite trend. This is primarily due to the fact that increasing boron doping increases the number of acceptor impurity atoms and reduces the boron acceptor activation energy, which together lead to an increase in the hole concentration. The Coulomb interaction between the doped impurities and carriers makes them more easily scattered by ionized impurities, thus reducing their mobility. When the boron-carbon ratio is 10 ppm, the carrier mobility of the diamond sample reaches 1429 cm²/(V·s) at 4.8×10¹⁴ cm⁻³ (carrier concentration); while the carrier mobility of the heavily doped diamond sample is only 19.2 cm²/(V·s) at 3.5×10¹⁷ cm⁻³ (carrier concentration). This shows that the boron-carbon ratio significantly affects the electrical properties of Boron-Doped Single Crystal Diamond. Therefore, the doping concentration of Boron-Doped Single Crystal Diamond epitaxy can be controlled by adjusting the boron-carbon atomic ratio in the feed gas.

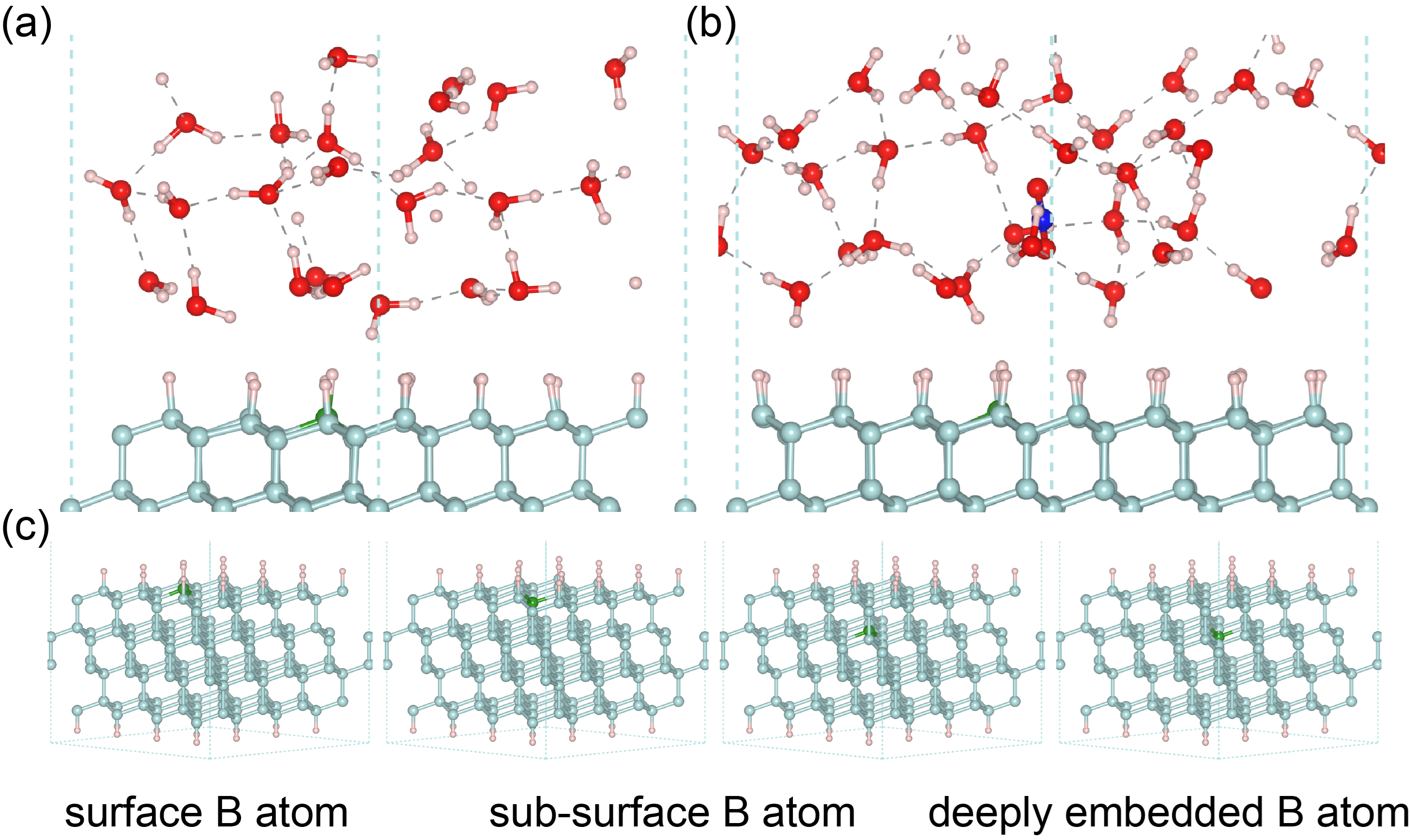

Key technical indicators of semiconductor power devices are primarily forward resistance and reverse breakdown voltage. Improving these indicators, in addition to designing a suitable device structure, is also crucial for enhancing the electrical properties of the doped diamond. Mobility is a key performance metric. Higher mobility means devices will more easily achieve higher response speeds and on-state conductivity. Figure 4(b) shows that the mobility of the samples grown in this work has reached a high level. Sample #1 achieved a mobility of 1429 cm²/(V·s) at a carrier concentration of 4.8×10¹⁴ cm⁻³, while sample #2 achieved a mobility of 1052 cm²/(V·s) at a carrier concentration of 1.5×10¹⁵ cm⁻³. Similar to the mechanism of sulfur-assisted boron-doped diamond, this is primarily due to the fact that the addition of the assist gas (oxygen) during growth enhances the plasma's etching of the non-diamond phase, reducing the likelihood of new defects during epitaxy and improving the crystal quality of the epitaxial layer. This, in turn, reduces the scattering effect of defects on carriers and enhances mobility.

In this work, boron-doped single-crystal diamond homoepitaxial thin films were grown using MPCVD. By controlling the B/C atomic ratio in the raw gas, the carrier concentration was regulated between 1014 and 1017 cm-3. Strategies including surface etching and backfilling, a two-step growth method, and low-temperature oxygen-assisted growth were proposed. The grown boron-doped single-crystal diamond has the advantages of high mobility and high thermal conductivity, making it very suitable as a material for high-frequency and high-power devices. In addition, due to the stability and radiation resistance of the diamond material itself, the grown boron-doped diamond is also an ideal material for making high-energy particle irradiation detectors. These devices will have a wide range of application scenarios in the future.

The boron-doped single-crystal diamond produced by CSMH can achieve doping from low concentration to high concentration. It has realized a uniform and controllable concentration and a customizable boron doping process.CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message