Pos:

Home KnowledgeTechnologyDiamond composite materials have become the core breakthrough for the fourth-generation heat sink materials.Heat dissipation heat sinks are a rigid demand for electronic devices and a key factor supporting the improvement of equipment performance. For every 10°C increase in the temperature of an electronic device, its service life decreases by 50%. The performance of heat sink materials determines the performance and reliability of the device. With the continuous increase in power and integration of equipment such as drones, robots, and AI computing devices, the demand for high-performance heat sink materials has become increasingly urgent.

Traditional heat sink materials (such as W/Cu, Mo/Cu, and SiC/Al) generally have a thermal conductivity of less than 200 W/(m·K), which makes it difficult to meet the heat dissipation requirements of high-power devices (such as GaN and SiC). Carbon materials represented by diamond and graphene, with their ultra-high thermal conductivity (diamond reaches 2200 W/(m·K)) and low coefficient of thermal expansion (diamond is only 1.2×10⁻⁶/K), have become the core breakthrough for the fourth-generation heat sink materials.

Ultra-High Thermal Conductivity

In electronic equipment, heat dissipation is a crucial issue. As the integration level of electronic equipment continues to improve, the power density of chips becomes higher and higher, and the heat generated also increases. If this heat cannot be dissipated in a timely and effective manner, the performance of the electronic equipment will be seriously affected, and it may even lead to equipment damage. The ultra-high thermal conductivity of diamond-copper makes it highly effective in the field of heat dissipation.

Taking 5G base stations as an example, the high data rate and low latency characteristics of 5G communication technology require components such as radio frequency chips in base stations to process large amounts of data, thereby generating a great deal of heat. Traditional heat dissipation materials are difficult to meet the heat dissipation needs of 5G base stations. However, heat dissipation components made of diamond-copper can quickly conduct heat away, ensuring the stability and reliability of base stations during high-frequency and high-power operation, and greatly improving communication quality and efficiency. According to relevant data, after using diamond-copper heat dissipation components, the average operating temperature of 5G base stations can be reduced by 25%, and power consumption can be reduced by 10%.

In terms of computer CPU heat dissipation, diamond-copper also performs exceptionally well. CPUs generate a lot of heat during operation. If the heat cannot be dissipated in a timely manner, the CPU will experience overheating and frequency reduction, which affects the operating speed of the computer. Heat dissipation fins made of diamond-copper can more efficiently transfer the heat generated by the CPU, maintaining the CPU in a low-temperature operating state and effectively improving the performance and stability of the computer. Compared with traditional pure copper heat dissipation fins, the use of diamond-copper heat dissipation fins can reduce the CPU temperature by 10-20°C, thereby providing a larger overclocking space for the CPU and improving the overall performance of the computer.

Low Coefficient of Thermal Expansion

The low coefficient of thermal expansion is another important characteristic of diamond-copper, which is of great significance for ensuring the stability and reliability of electronic devices. In electronic devices, differences in the coefficient of thermal expansion of different materials may lead to thermal stress when the temperature changes, thereby affecting the performance and service life of the device.

Taking satellite electronic equipment as an example, when a satellite operates in space, it experiences huge temperature changes, ranging from high temperatures when exposed to direct sunlight to low temperatures in the shadow, with a temperature difference of up to several hundred degrees Celsius. Under such extreme temperature conditions, the materials of electronic equipment must have good dimensional stability to ensure the normal operation of the equipment. The low coefficient of thermal expansion of diamond-copper results in minimal dimensional changes when the temperature changes. This allows it to achieve a good match with other materials in satellite electronic equipment, effectively avoiding stress damage caused by thermal expansion and contraction, and improving the reliability and service life of satellite electronic equipment.

In semiconductor devices, the low coefficient of thermal expansion of diamond-copper also plays a key role. Semiconductor chips are usually composed of a variety of materials, each with different coefficients of thermal expansion. When the chip is working, due to the increase in temperature, different materials expand to different degrees, generating thermal stress, which may cause problems in the circuit connections inside the chip and affect the performance of the chip. However, when diamond-copper is used as the packaging material or heat dissipation substrate of the chip, its low coefficient of thermal expansion can match the coefficient of thermal expansion of the semiconductor chip, reducing the generation of thermal stress and ensuring the stable operation of the chip.

High Hardness and Wear Resistance

In some extreme working conditions, materials need to have high hardness and wear resistance to ensure the normal operation and service life of equipment. Relying on its high hardness and excellent wear resistance, diamond-copper has been widely used in fields such as aerospace and automobile manufacturing.

In the aerospace field, components of aircraft need to withstand the effects of various complex factors such as air friction during high-speed flight, mechanical vibration, and radiation in the space environment. The high hardness of diamond-copper enables it to resist air friction and the impact of small meteorites, and its excellent wear resistance ensures the performance stability of components during long-term use. For example, in components such as the wing edge protectors of aircraft and the precision instrument brackets of satellites, the use of diamond-copper materials can effectively reduce weight while improving the wear resistance and reliability of the components, ensuring the safe operation of aircraft and satellites in harsh space environments.

In the field of automobile manufacturing, components such as engine pistons and cylinders are subject to high temperatures, high pressures, and high-speed friction during operation. The high hardness and wear resistance of diamond-copper make it an ideal material for manufacturing these components. Engine components made of diamond-copper can significantly improve the wear resistance and fatigue resistance of the components, reduce engine wear and failures, extend the service life of the engine, and at the same time improve the efficiency of the engine and reduce fuel consumption and emissions.

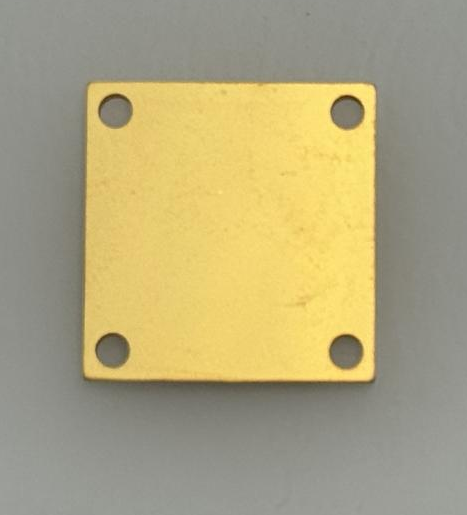

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), and the surface roughness of diamond wafer a<1nm.It has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message