Pos:

Home KnowledgeTechnologyDiamond Enhances the Overall Performance and Heat Dissipation of High-Power Semiconductor Laser ArraysVertical-Cavity Surface-Emitting Lasers (VCSELs) possess advantages such as symmetric light beams, low threshold current, high-speed modulation, single longitudinal mode operation, no catastrophic optical mirror damage, and ease of fabricating dense two-dimensional arrays. They are widely used in fields including laser pumping, infrared laser light sources, optical storage, three-dimensional sensing, and optical detection.

Among the high thermal conductivity materials currently under development, diamond is more suitable for high-power devices and extremely complex environments due to its hardness, insulation, and stability. The combination of its unique lattice structure and strong covalent electronic bonds results in a large capacity for heat conduction through phonons. Additionally, its low dielectric loss, low friction coefficient, transparency over a wide spectral range, high hardness, chemical inertness, and variable thermal expansion coefficient enable it to effectively eliminate shear stress. Therefore, diamond exhibits remarkably prominent advantages in thermal management.

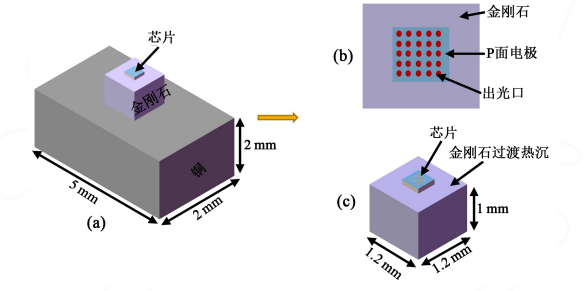

The advantage of using a diamond transition heat sink lies in its ability to rapidly conduct the heat generated by the chip to the copper heat sink while maintaining electrical insulation from the copper heat sink, thereby facilitating the design of large-area packaging structures. To investigate the impact of the diamond transition heat sink on the temperature of VCSEL arrays, finite element analysis was employed to simulate and study the heat dissipation performance of VCSEL arrays after the integration of the transition heat sink. The temperature uniformity among the array units was evaluated by examining the temperature difference between the maximum and minimum temperatures in the laser array.

For the VCSEL array with a traditional packaging structure, the maximum temperature reached 39.882°C and the minimum temperature was 36.237°C, resulting in a temperature difference of 3.645°C among the light-emitting units. The highest temperature was located at the center of the light-emitting units, while the lowest temperature was at the edges. Heat generated by the light-emitting units accumulated in the central region, leading to the highest temperature at this location. After incorporating the diamond transition heat sink, the maximum temperature of the array decreased to 38.856°C, the minimum temperature dropped to 35.547°C, and the temperature difference among the light-emitting units narrowed to 3.309°C.

Therefore, compared with the traditional packaging structure, the diamond transition heat sink not only reduces the temperature of the VCSEL array but also decreases the temperature difference between the maximum and minimum temperatures of the light-emitting units. This is because the heat generated inside the array is primarily conducted from the chip to the heat sink through thermal conduction. Using diamond as the transition heat sink enables rapid dissipation of the heat generated by the chip, additionally increasing the heat dissipation paths of the packaging structure and weakening the thermal crosstalk between adjacent light-emitting units.

Utilizing diamond—an ultra-high thermal conductivity material—as a heat sink can improve the thermal conduction efficiency of high-power semiconductor lasers by 1.5 to 2.0 times compared to traditional heat sinks. Furthermore, employing diamond as the heat sink for high-efficiency quantum dot-based vertical external cavity surface-emitting lasers (VECSELs) enhances the temperature uniformity of the active region. Thus, diamond exhibits significant advantages in improving thermal conduction.

If diamond (a high thermal conductivity material) is combined with copper (a traditional thermal conductive material) to fabricate a composite heat sink, it not only increases the thermal conductivity but also modifies the heat flow direction inside the heat sink. This plays a crucial role in reducing the thermal crosstalk effect between the light-emitting units of VCSEL arrays, thereby significantly enhancing the performance of the lasers.

CSMH uses the MPCVD method to prepare large-sized and high-quality diamonds,and currently has mature products such as diamond heat sinks, diamond wafers, diamond windows,diamond hetero junction integrated composite substrates,etc.Among them,the thermal conductivity of diamond heat sinks is 1000-2200w/(m.k), and the surface roughness of diamond wafer a<1nm.It has been applied in aerospace, high-power semiconductor lasers, optical communication, chip heat dissipation, nuclear fusion and other fields.

闽ICP备2021005558号-1

闽ICP备2021005558号-1Leave A Message